Brass and red copper (pure copper or copper alloys with a high copper content, such as oxygen-free copper) are widely recognized for their antioxidant properties, meaning they resist oxidation and corrosion better than many other metals. Here's why both materials are known for these qualities:

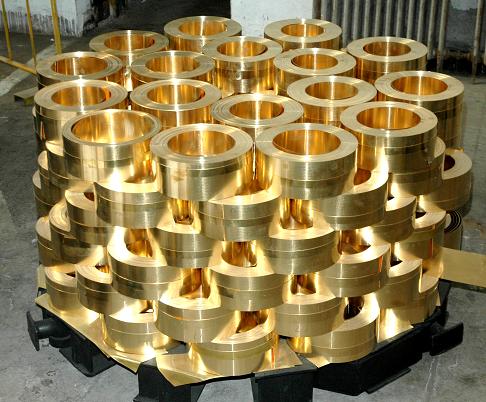

Brass

Brass is an alloy primarily composed of copper and zinc, with the potential addition of other elements like lead, aluminum, or tin to enhance specific properties.

Reasons Brass is More Antioxidant:

Corrosion Resistance:

Brass is known for its natural corrosion resistance, particularly against tarnishing and oxidation. The zinc content in brass creates a protective layer of zinc oxide on the surface when exposed to air, which slows down further oxidation.

Durability in Various Environments:

Brass is highly resistant to atmospheric corrosion, making it ideal for use in marine, outdoor, and industrial environments where resistance to moisture, water, and air is crucial.

Patina Formation:

Over time, brass develops a patina, a greenish or brownish layer that forms as a result of oxidation. This patina provides a protective barrier that further prevents corrosion, unlike rust in steel, which can degrade the metal.

Resistance to Dezincification:

Special types of brass, such as dezincification-resistant (DZR) brass, have a higher resistance to corrosion in harsh conditions, like those involving water with high chloride content.

Red Copper (Pure Copper or High-Copper Alloys)

Red copper, often referred to as pure copper or high-copper alloys like oxygen-free copper, is highly valued for its exceptional electrical and thermal conductivity, as well as its resistance to oxidation.

Reasons Red Copper is More Antioxidant:

Natural Oxidation Layer:

Pure copper forms a natural oxide layer when exposed to oxygen. This layer, called copper oxide, is relatively stable and protects the underlying metal from further corrosion. Unlike iron rust, which flakes away and exposes new layers of metal to corrosion, copper oxide adheres tightly to the surface and shields the metal beneath.

High Copper Content:

High-purity copper, like oxygen-free copper (99.99% copper), has fewer impurities, which contributes to its enhanced resistance to oxidation. The lack of oxygen and impurities makes it less susceptible to forming non-protective corrosion products.

Resistance to Industrial and Environmental Pollutants:

Copper is resistant to various industrial pollutants, chemicals, and salts, especially when alloyed with other elements like silver or tin. This makes copper an excellent choice for environments exposed to pollutants, seawater, or acids.

Patina Development:

Like brass, copper develops a patina (a greenish layer of copper carbonate or sulfide) over time, which is aesthetically appealing and acts as a protective shield against further oxidation. This is particularly beneficial for architectural applications and artworks.

Comparisons and Applications

Brass:

Applications: Fittings, valves, musical instruments, marine hardware, and decorative items.

Advantages: Highly resistant to corrosion, durable in outdoor environments, and has a pleasant golden color.

Drawbacks: Can suffer from dezincification in certain environments, especially where the zinc component is compromised.

Red Copper:

Applications: Electrical components, plumbing, roofing, architectural elements, and high-end electronics.

Advantages: Excellent electrical and thermal conductivity, highly resistant to oxidation, and forms a protective patina.

Drawbacks: It can tarnish and change color over time (which some may find undesirable), and it is softer than brass, making it less suitable for high-wear applications.

Conclusion

Both brass and red copper are more antioxidant compared to many other metals due to their unique properties. Brass, with its zinc content, is highly resistant to tarnishing and corrosion, while red copper forms a stable oxide layer that protects against further oxidation. The choice between these materials depends on the specific application requirements, including conductivity, corrosion resistance, strength, and aesthetic considerations.