The cathode plate production line is a cutting-edge system designed for the efficient and high-quality production of copper cathode plates. These plates are the final product of a series of intricate processes that begin with copper ore and result in pure electrolytic copper plates. This production line is vital in the refining of copper ore into copper cathode plates, which are then used in various industrial applications, from electronics to construction. The production line is designed to handle large-scale operations, ensuring a consistent output of high-purity copper cathode plates.

Technical Advantages

High Efficiency:

The cathode plate production line is engineered to maximize efficiency at every stage of production. From the initial processing of copper ore to the final electrolysis, each component of the production line is optimized for speed and precision, ensuring a high yield of copper cathode plates.

Advanced Electrolytic Process:

Utilizing state-of-the-art technology, the production line excels in the electrolysis phase, where copper ore is transformed into pure copper cathode plates. The process is finely tuned to minimize impurities, resulting in high-quality electrolytic copper plates that meet industry standards.

Durable Anode Plates:

The production line is equipped with robust anode plates that contribute to the longevity and efficiency of the electrolysis process. These anode plates are designed to withstand the harsh conditions of electrolysis, ensuring a longer operational life and consistent quality of the copper cathode plates.

Energy Efficiency:

In today's environmentally conscious market, energy efficiency is a key consideration. The cathode plate production line is designed to minimize energy consumption, making it an eco-friendly option for large-scale copper production. This not only reduces operational costs but also aligns with global sustainability goals.

Automated Operations:

The production line incorporates advanced automation technologies that reduce the need for manual intervention. This not only increases safety but also enhances the precision of the production process, ensuring that every copper cathode plate produced is of the highest quality.

Application Areas

The cathode plate production line has wide-ranging applications across various industries. The high-purity copper cathode plates produced are essential in the following sectors:

Electronics:

Copper cathode plates are a crucial component in the manufacturing of electronic devices. The high conductivity and purity of the electrolytic copper plates make them ideal for use in wiring, circuit boards, and other electronic components.

Construction:

In the construction industry, copper cathode plates are used in plumbing, roofing, and cladding. Their durability and resistance to corrosion make them a preferred choice for various structural applications.

Energy and Power Generation:

Electrolytic copper plates are used in the production of power cables and transformers, playing a vital role in energy distribution and transmission systems.

Automotive Industry:

The automotive sector relies on copper cathode plates for the production of electrical systems in vehicles, including wiring harnesses and electric motor components.

Telecommunications:

Copper cathode plates are also used in the manufacturing of telecommunication cables, ensuring reliable and high-speed data transmission.

Operation Process

The operation process of the cathode plate production line is meticulously designed to ensure efficiency and high-quality output. The process involves several key stages:

Ore Processing:

The process begins with the extraction and processing of copper ore. The ore is crushed and ground to liberate the copper minerals, which are then concentrated and purified through flotation.

Smelting and Refining:

The concentrated copper ore undergoes smelting to produce copper anodes, which contain impurities. These anodes are then subjected to electrolysis, where the copper is further purified.

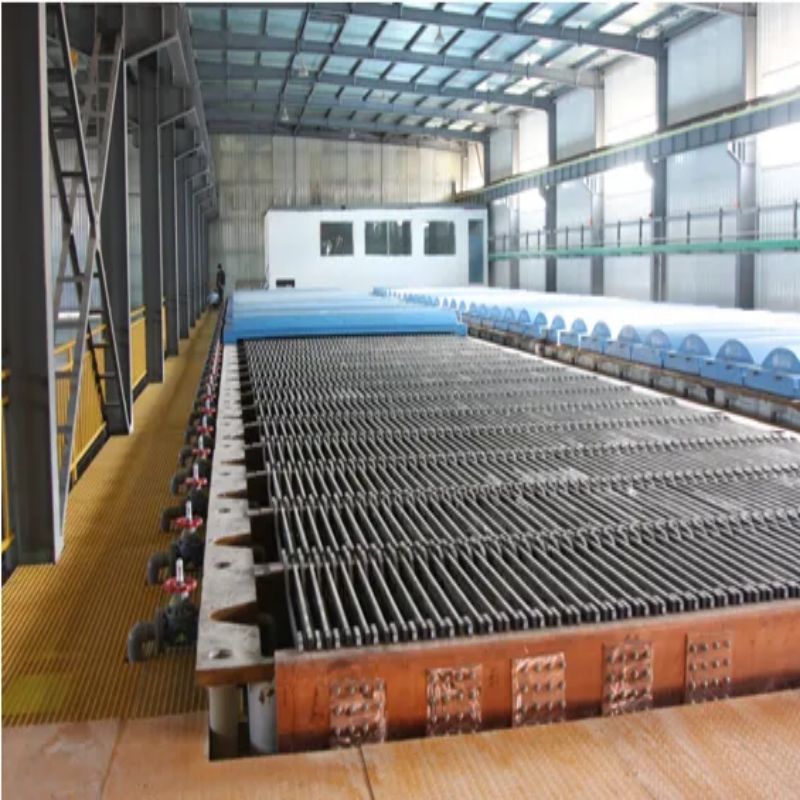

Electrolysis:

During electrolysis, the anode plates are submerged in an electrolyte solution, and an electric current is applied. Copper ions from the anode dissolve into the solution and deposit onto the cathode, forming pure copper cathode plates.

Final Processing:

After electrolysis, the copper cathode plates are removed, cleaned, and inspected for quality. They are then cut and shaped according to customer specifications before being packaged for shipment.

Customer Feedback

Customers who have implemented the cathode plate production line in their operations have reported significant improvements in productivity and product quality. Here are some of the key feedback points:

Improved Purity:

Customers have praised the production line for its ability to produce copper cathode plates with exceptional purity, meeting stringent industry standards and exceeding expectations in terms of quality.

Operational Efficiency:

The automated features and energy-efficient design of the production line have resulted in reduced operational costs and increased output, making it a cost-effective solution for large-scale production.

Consistent Quality:

The durability of the anode plates and the precision of the electrolysis process have ensured consistent production of high-quality electrolytic copper plates. Customers have noted a significant reduction in defects and rework, contributing to overall operational efficiency.

Ease of Maintenance:

The production line's design allows for easy maintenance and minimal downtime, which has been a major advantage for customers looking to maximize their production schedules.

Market Prospects

The market prospects for the cathode plate production line are highly promising, driven by the increasing demand for copper cathode plates across various industries. Several factors contribute to the positive outlook for this production line:

Growing Demand for Copper:

As the global demand for copper continues to rise, the need for high-quality copper cathode plates is expected to increase. This production line is well-positioned to meet this demand, offering manufacturers the ability to produce large volumes of electrolytic copper plates efficiently.

Expansion of Industrial Applications:

The expansion of industries such as electronics, construction, and telecommunications is driving the demand for copper cathode plates. The versatility and reliability of the cathode plate production line make it an ideal solution for manufacturers looking to serve these growing markets.

Sustainability and Environmental Responsibility:

With a focus on sustainable and environmentally responsible manufacturing practices, the cathode plate production line offers an energy-efficient solution that reduces the environmental impact of copper production. This aligns with global trends toward sustainability and offers a competitive edge in the market.

Technological Advancements:

The continuous development of new technologies and materials is expected to drive the demand for high-purity copper cathode plates. The production line's advanced technology ensures that manufacturers can stay ahead of industry trends and meet the evolving needs of their customers.

Global Market Expansion:

The global market for copper cathode plates is expanding, with significant growth opportunities in regions such as Asia, Europe, and North America. The cathode plate production line offers manufacturers the ability to serve a diverse range of markets, ensuring a strong presence in the global copper industry.

In conclusion, the cathode plate production line is a state-of-the-art solution for the production of high-quality copper cathode plates. With its advanced technology, energy efficiency, and wide-ranging applications, this production line is poised to play a key role in the future of copper production. Whether you're looking to increase your production capacity, improve product quality, or reduce operational costs, the cathode plate production line offers the capabilities you need to succeed in today's competitive market.