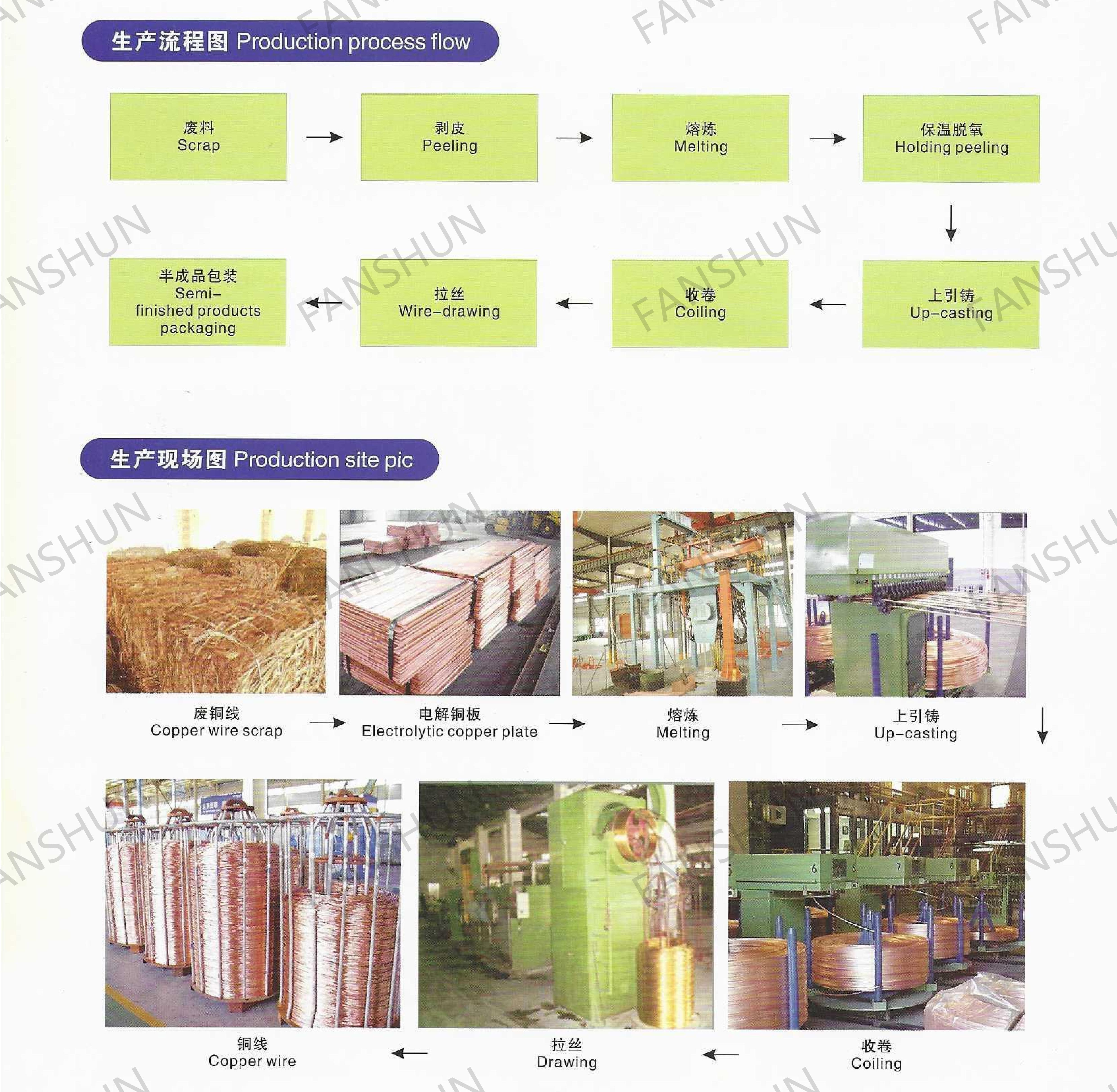

| In the realm of copper processing, the journey from discarded materials to refined products involves a series of crucial steps. At the forefront of this process is the copper slag smelting furnace. These copper slag smelting furnace are instrumental in the initial stage of recycling, where copper slag, a byproduct of various copper manufacturing processes, is melted down to extract usable copper.

The Copper slag smelting furnace is vital in recycling copper. Copper slag smelting furnace melts down copper slag, extracting usable copper. This copper is then shaped into oxygen-free copper bars, crucial for high-conductivity applications in electronics and telecommunications. The Copper slag smelting furnace ensures efficient utilization of copper resources.

Another essential component of copper processing is the iron rod straightening machine. This iron rod straightening machine ensures that copper rods, a fundamental building block in many industries, are shaped to precise specifications, ready to be utilized in construction, electrical wiring, and other applications.

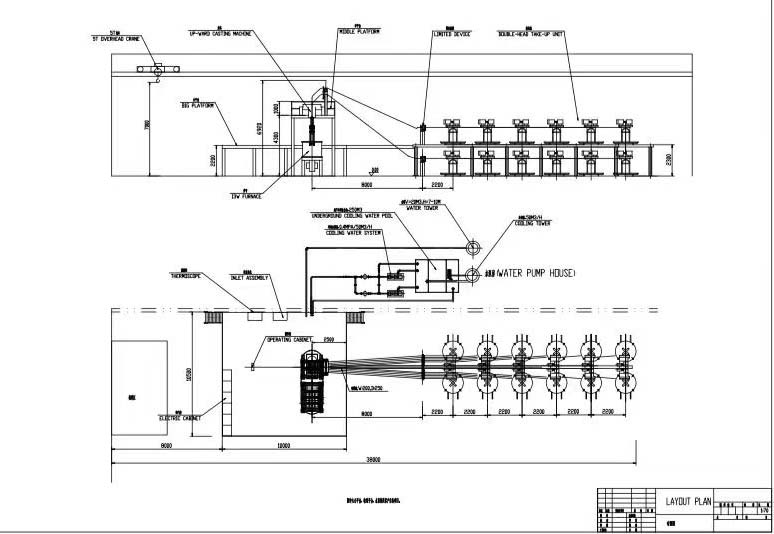

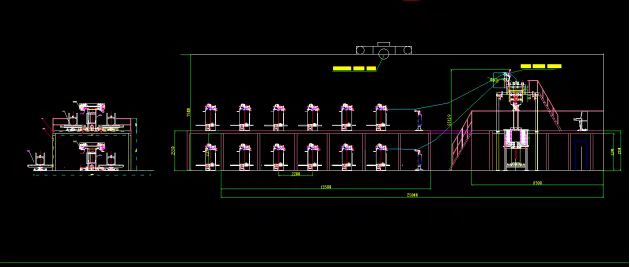

Moreover, copper can also be processed into bronze wire, which finds applications in art, sculpture, and electrical conductivity due to bronze wire unique properties. Bronze wire production is another significant aspect of utilizing refined copper materials effectively. In the realm of advanced manufacturing, oxygen-free copper bar up casting production lines represent cutting-edge technology. These oxygen-free copper bar up casting production lines ensure the production of high-quality copper bars with minimal oxygen content, enhancing the material's conductivity and durability. Oxygen-free copper bars are highly sought after in industries requiring superior electrical conductivity, such as electronics and telecommunications. The Scrap copper melting furnace is essential for recycling copper. Scrap copper melting furnace melts scrap copper to produce oxygen-free copper bars. These bars are prized for their high conductivity and durability, serving diverse industries. The Scrap copper melting furnace plays a key role in sustainable copper production. In summary, the journey from copper slag to oxygen-free copper bars involves several key processes, including smelting, refining, shaping, and advanced casting. Each step contributes to the efficient utilization of copper resources and the production of high-quality materials essential for various industries. The Oxygen free copper bar up casting production line stands as a pinnacle in this process, epitomizing innovation and excellence in copper manufacturing technology. |