Application

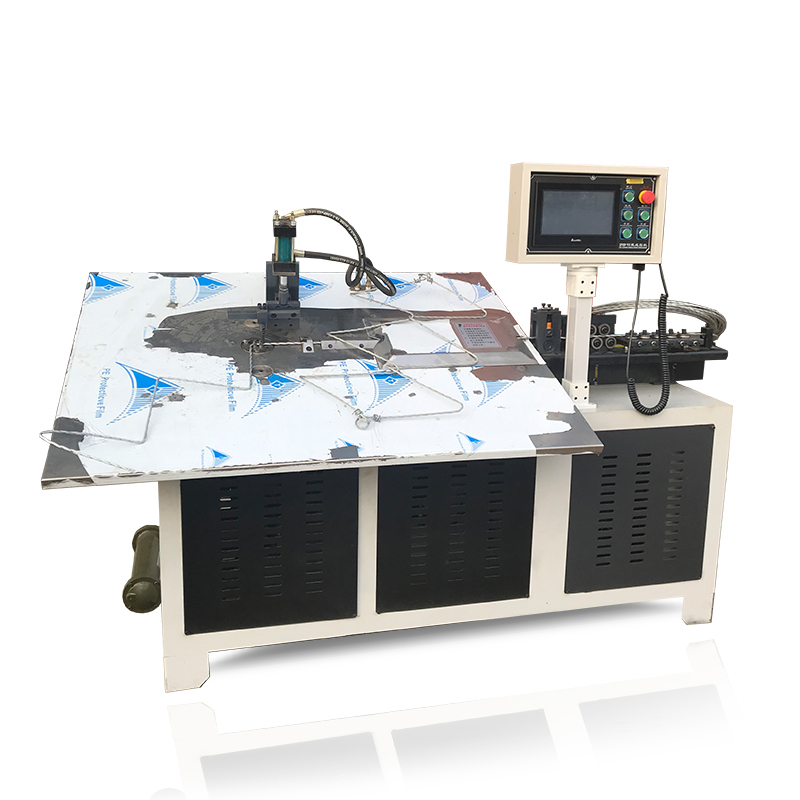

2D CNC FULLY AUTOMATIC WIRE BENDING MACHINE

General Description:

2D CNC Fully Automatic Wire Bending Machine is mainly used for bending and forming various metal wire into different shape in two-dimensional.

The wire feeding and rotary bending system both adopt servo motor,significantly improves the precision of the product, and increases the speed and flexibility of machine effectively,furthermore greatly improves the production efficiency.

According to the characteristics of wire processing, various kinds and shapes,we specially design the controlling system with a memory storage function,which can save more than 100sets of processing program for different products, can optionally select any one of them when needed.

Main Technical Parameters:

Model No. | WB2-6MM | WB3-10MM |

Main Parameters |

Input Voltage | 220V, 380V, 415V,480V, 50/60HZ, 3P |

Wire Diameter Range | 2-6MM | 3-10MM |

Max Wire Feeding Instruction Value | 10000MM | 10000MM |

Mini Wire Feeding Instruction Value | 0.01MM | 0.01MM |

Max Wire Feeding Speed | 70M/Min | 50M/Min |

Wire Feeding Accuracy | ±0.2mm | ±0.2mm |

Max Bending Speed | 100Turns/Min | 100Turns/Min |

Bending Accuracy | ±0.5mm | ±0.5mm |

Machine Dimension | L:280*W:90*H:170cm | L:370*W:120*H:180cm |

Machine Weight | 950KG | 1500KG |

Functions

Main Features and Functions:

1.A full range of CNC Programmable wire bending machines for two-dimensional wire bending and forming, is manufactured according to European machine standards;

2.Heavy duty mechanical structures and minimum setup requirements due to reasonably design.

3.Friendly man-machine interface, user friendly programming, easy to operate.

4.Two groups of strong roller subassemblies powered with a servomotor ensure accurate wire feeding and excellent straightening.

5.Automatic wire straightening, feeding, forming and recording the amount.The wire product size and parameters and presetting quantity,can also change and modify during producing.

6.Available for forming and bending different diameter of steel wire,iron wire, stainless steel wire, copper and aluminum wire,also other metals,which shape is round, flat, square, hexagonal, etc.Widely used in the industry of wire products, fan nets, handicrafts, lampshades etc...