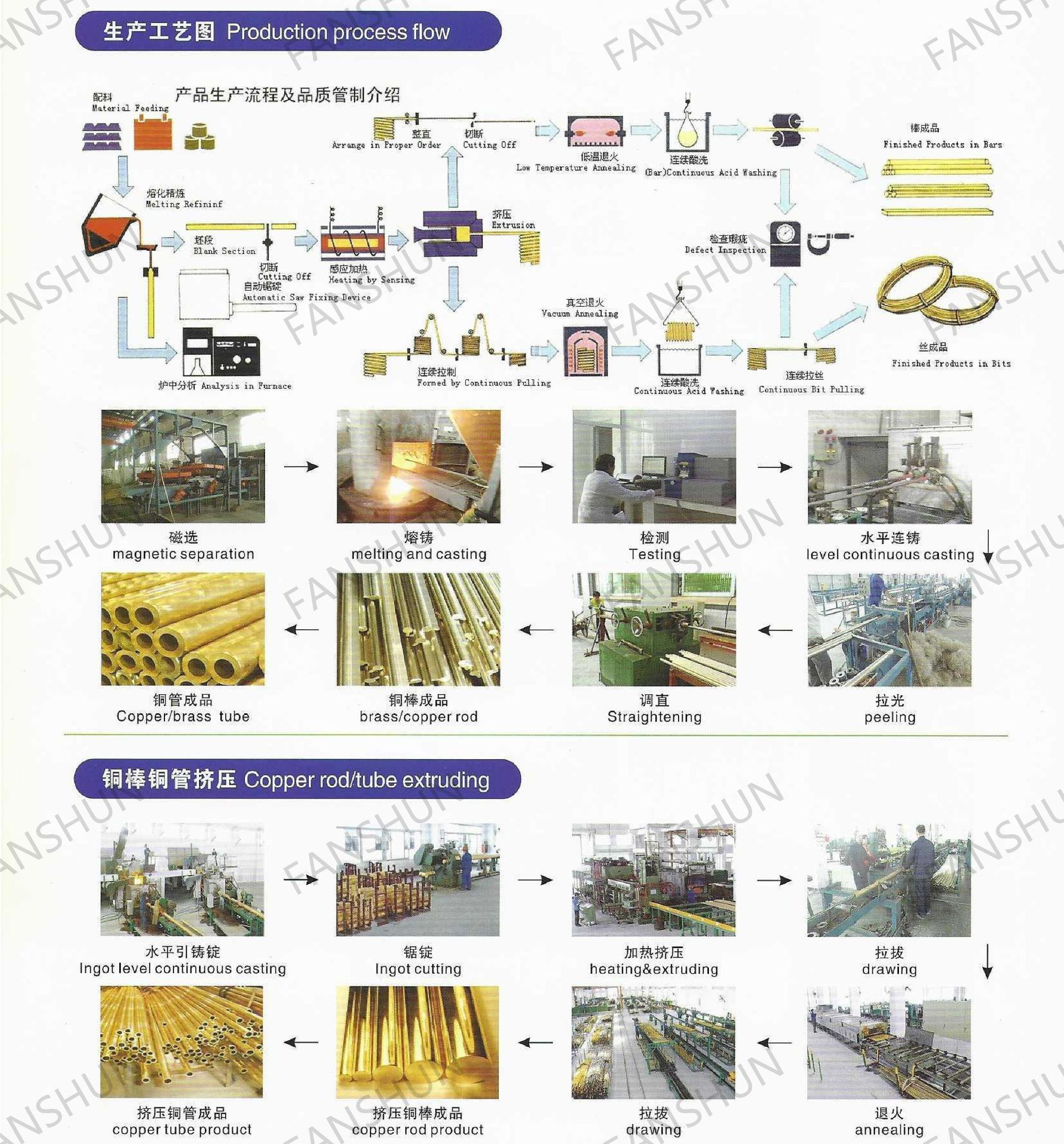

Melting Furnace: The process begins with melting high-purity copper in a melt furnace. A reverberatory furnace or induction furnace is commonly used to melt the copper, often from cathode copper or recycled scrap.

Upward Continuous Casting Machine: The molten copper is cast into thick copper rods using an upward continuous casting system. This casting method ensures the production of copper rods with high purity and precise dimensions, which are critical for air conditioning pipes.

Rolling Mill: After casting, the thick copper rods are rolled in a rolling mill to reduce their diameter and achieve the desired thickness.

Drawing Machine: The rolled copper rods are drawn through a series of dies in a hydraulic or mechanical drawing machine to reduce the rod’s diameter further. The process is done progressively to create pipes with the required thickness and diameter for air conditioning systems.

The drawing process makes the copper pipes thin-walled and suitable for use in air conditioning units.

Annealing Furnace: After the drawing process, the copper pipes are often annealed in an annealing furnace to soften the material, improve ductility, and remove internal stresses. Annealing is crucial for making the copper pipes malleable, which is necessary for bending and installation in air conditioning units.

Continuous Annealing: Some production lines use continuous annealing to ensure consistent heating of copper pipes while maintaining their desired mechanical properties.

Cleaning Process: The copper pipes undergo a cleaning process to remove any surface impurities, residues, or oxides that may have formed during the production stages.

Coating (Optional): Depending on the customer’s requirements, the copper pipes may be coated with protective layers or treated to enhance corrosion resistance or appearance, though this is optional for air conditioning copper pipes.

Sizing and Straightening: The pipes are passed through sizing and straightening machines to ensure that they meet precise dimensional requirements, including uniform diameter, thickness, and straightness.

Cutting Machine: The copper pipes are then cut to the desired lengths using automatic cutting machines to meet the specifications needed for air conditioning systems. The lengths vary depending on the application and installation requirements.

Surface Polishing and Inspection: The pipes may undergo surface polishing to improve their appearance and ensure a smooth finish, which is essential in certain HVAC systems. A final inspection is carried out to check for defects and ensure dimensional accuracy.

Coiling: The pipes are coiled into specific lengths for easier transportation and installation. Coiling also reduces the chances of damage during transport.

Packaging: The coiled or straight pipes are then packaged according to customer requirements, often in protective covers or spools to prevent damage during shipment.

ACR (Air Conditioning and Refrigeration) Pipes: These pipes are specially designed for refrigeration and air conditioning systems, with precise internal diameters to accommodate refrigerants.

Soft Copper Tubing: This type is more flexible and used where pipes need to bend without fittings, such as in residential HVAC systems.

Hard Copper Tubing: Rigid copper pipes used where straight lines of piping are required, such as in commercial air conditioning installations.

High Thermal Conductivity: Copper is ideal for transferring heat, which is essential for efficient air conditioning systems.

Corrosion Resistance: Copper pipes resist corrosion, which is important in air conditioning systems where pipes are exposed to moisture and chemicals.

Durability: Copper is highly durable and can withstand high pressure, making it suitable for long-term use in HVAC systems.

Flexibility: Copper pipes can be easily bent or shaped, which is necessary for fitting into tight spaces in HVAC units.

An air conditioning copper pipe production line is an intricate process involving melting, casting, drawing, annealing, and finishing to produce high-quality copper pipes for HVAC applications. These pipes are critical components in air conditioning and refrigeration systems, and the production line ensures that they meet strict standards for durability, corrosion resistance, and heat transfer efficiency.