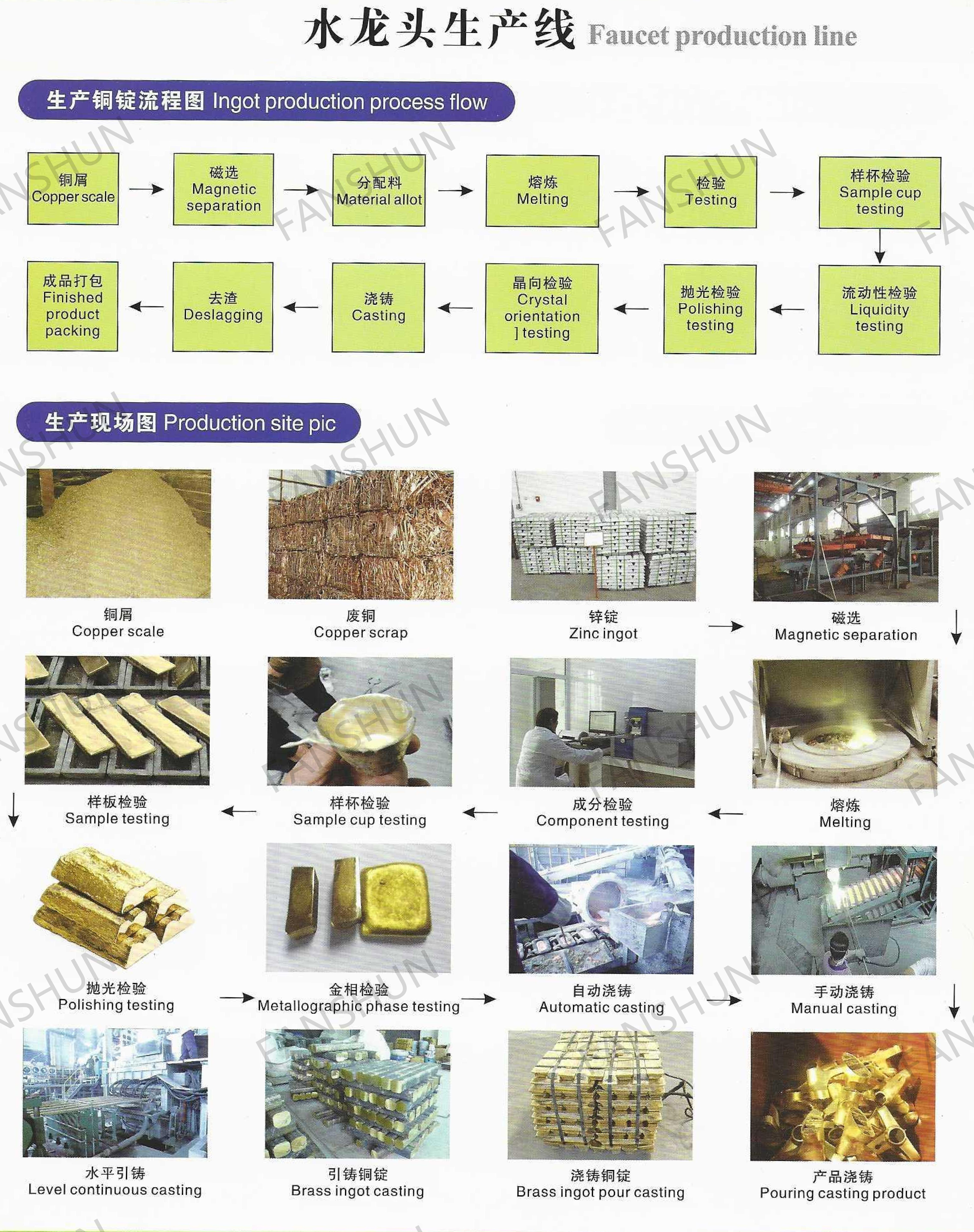

3D Animation Preview

| More information about the 3D animation,please "contact us". |

Equipment Configuration Reference

| Magnetic Separator | Vibratory Feeder | Mixer | Furnace | Casting Machine | Environmental Equipment(optional) |

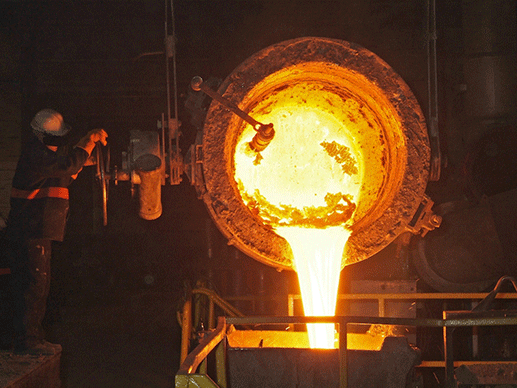

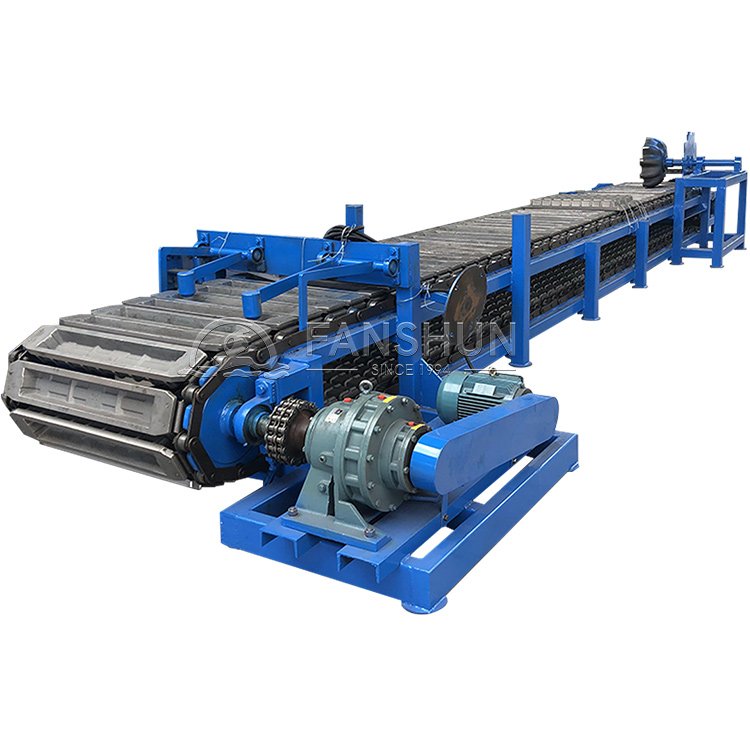

| At the heart of the production line is the Copper Melting Furnace. This Copper Melting Furnace is responsible for heating raw copper materials to a molten state, preparing them for casting. The Copper Melting Furnace must maintain a consistent temperature to ensure the copper melts uniformly, which is essential for producing high-quality copper ingots. In this process, the Copper Furnace—a more general term for the various types of furnaces used—plays a vital role. The Copper Furnace is specifically designed to handle the high temperatures required to melt copper efficiently. Once the copper is melted in the Copper Melting Furnace, it is transferred to the Copper Ingot Casting Machine. This machine is the core of the Copper Ingot Casting Line for Faucet Production. The Copper Ingot Casting Machine takes the molten copper from the Copper Furnace and carefully pours it into molds to form copper ingots. The precision of the Copper Ingot Casting Machine is crucial, as it determines the shape, size, and overall quality of the copper ingots. The Copper Ingot Casting Machine is designed to handle the high demands of continuous production, ensuring that each copper ingot meets the exact specifications required for faucet manufacturing. The Copper Ingot Casting Machine is equipped with advanced controls to monitor the casting process, ensuring that the molten copper is poured at the right rate and temperature to produce copper ingots with a consistent quality. The entire process, from the Copper Melting Furnace to the Copper Ingot Casting Machine, is optimized to produce copper ingots that are free from impurities and defects. These copper ingots are then used in the production of faucets, where the purity and consistency of the copper are critical to ensuring the final product's durability and appearance. In summary, the Copper Ingot Casting Line for Faucet Production relies on a series of highly specialized equipment, including the Copper Melting Furnace, Copper Furnace, and Copper Ingot Casting Machine. These components work together to produce high-quality copper ingots that are essential for faucet manufacturing, ensuring that each faucet meets the highest standards of quality and durability. The efficiency and precision of the Copper Ingot Casting Machine, along with the reliable performance of the Copper Melting Furnace and Copper Furnace, are key to the success of this production line. |

| Magnetic Separator |

| Vibratory Feeder |

| Mixer |

| Furnace |

| Casting Machine |

| Environmental Equipment |