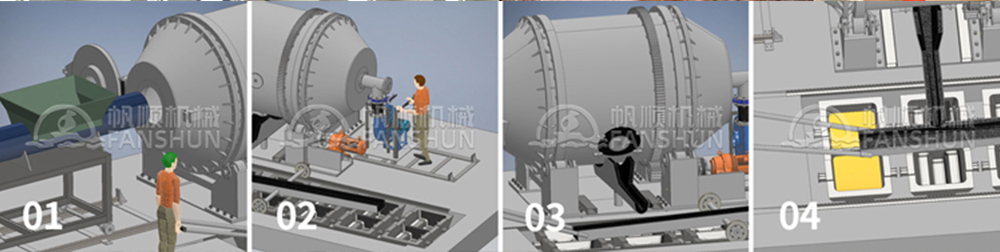

The production process for refining metals relies on a series of rotary furnaces: the Copper refining rotary furnace, Automatic tilting furnace, Rotary calcination furnace, and Rotary furnace, with a specific focus on the Rotary furnace for aluminium melting.The Copper refining rotary furnace serves as a primary tool for purifying copper, melting down raw materials to eliminate impurities. Complementing this, the Automatic tilting furnace streamlines the process by automatically tilting to pour molten copper into molds or casting equipment, enhancing efficiency. Automatic tilting furnaces are typically large, industrial-grade machines equipped with a tilting mechanism that allows them to automatically pour molten material.The Automatic tilting furnace revolutionizes metal processing.Meanwhile, the Rotary calcination furnace facilitates the conversion of various materials through controlled heating, crucial for pre-treatment processes in metal refinement. The Rotary calcination furnace, with its rotating design, facilitates controlled heating for material conversion.The generic Rotary furnace serves multifaceted roles in different stages of production, offering flexibility and adaptability.Lastly, the Rotary furnace for aluminium melting specializes in melting aluminium, ensuring precise temperature control and efficient melting processes. The Rotary furnace for aluminium melting employs its rotating mechanism to efficiently and precisely melt aluminium. |