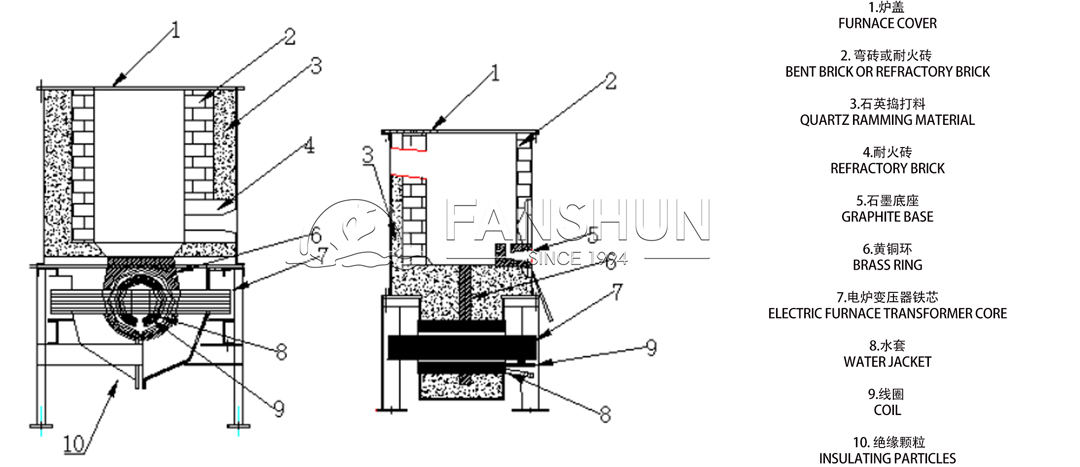

The Power frequency induction copper melting furnace is a highly efficient tool for melting copper rods. Using electromagnetic induction,Power frequency induction copper melting furnace rapidly heats the metal, ensuring precise temperature control. Power frequency induction copper melting furnace is widely used in metallurgical processes for its reliability and energy efficiency in copper melting operations. Hold furnaces play a crucial role in the melting process, Hold furnaces controlled environment ensures consistency and quality in casting operations,Hold furnaces making it indispensable in metallurgical production.Hold furnaces precise temperature control ensures uniformity and quality in production. Hold furnaces ensure consistency in metal quality and facilitate seamless production processes. Iron furnaces are another type commonly used in metal rod melting operations. These Iron furnaces are versatile and can handle a wide range of metal types, including iron and steel, Iron furnaces making them indispensable in foundries and manufacturing facilities.The Iron furnace ensures reliability and precision in metallurgical operations.

The Casting Copper and Aluminum Metal Melting Induction Furnace represents a modern approach to metal melting, utilizing electromagnetic induction to generate heat within the metal itself. Casting Copper and Aluminum Metal Melting Induction Furnace utilizes electromagnetic induction to efficiently melt copper and aluminum. Casting Copper and Aluminum Metal Melting Induction Furnace ensures precise temperature control, making it indispensable in casting operations for high-quality metal products.

The Die casting furnace Scrap metal aluminum melting furnace are specialized in melting aluminum for die casting operations. These Die casting furnace Scrap metal aluminum melting furnaces efficiently melt scrap aluminum, ensuring material reuse and reducing waste. Die casting furnace Scrap metal aluminum melting furnaces are integral to sustainable metal production and uphold efficiency in die casting processes. In summary, metal rod melting furnaces come in various types, each tailored to specific metal melting requirements. Whether it's the Power frequency induction copper melting furnace, hold furnace, iron furnace, Casting Copper and Die casting furnace Scrap metal aluminum melting furnace, each plays a vital role in the efficient and precise melting of metals for casting and fabrication applications. |