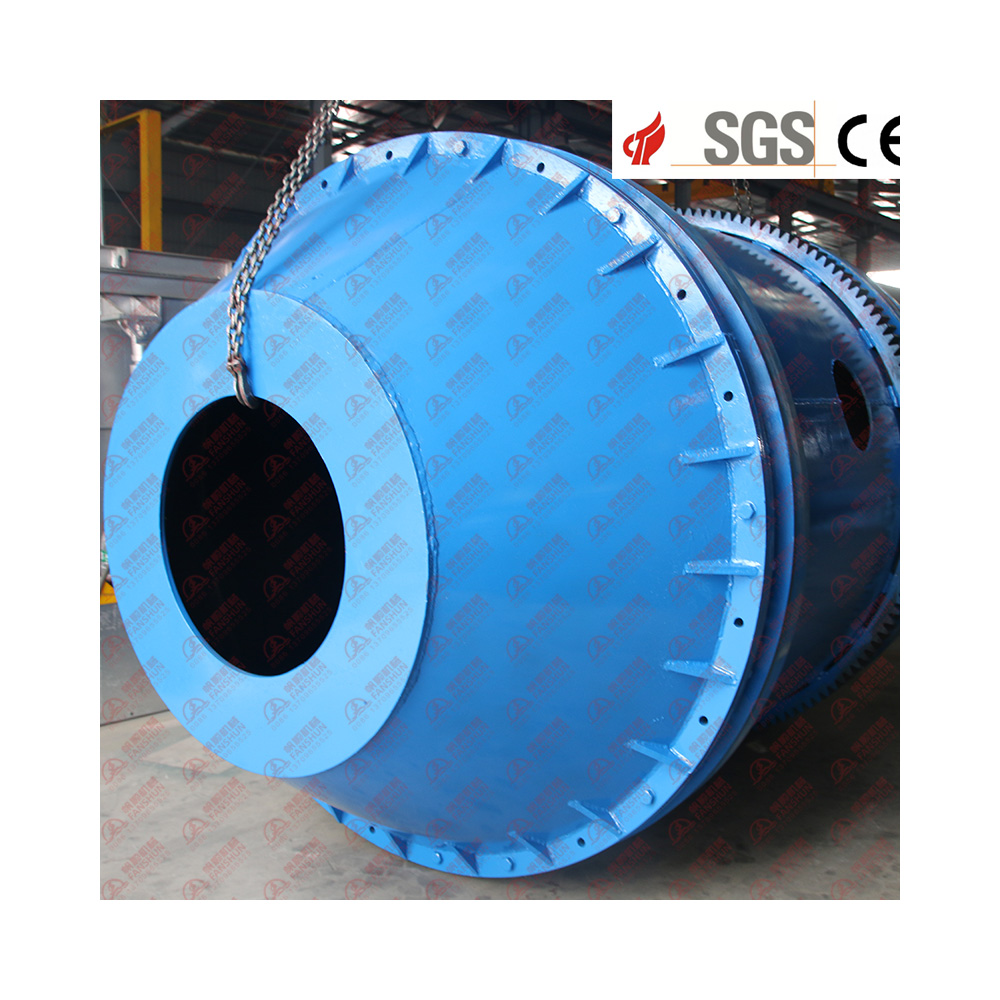

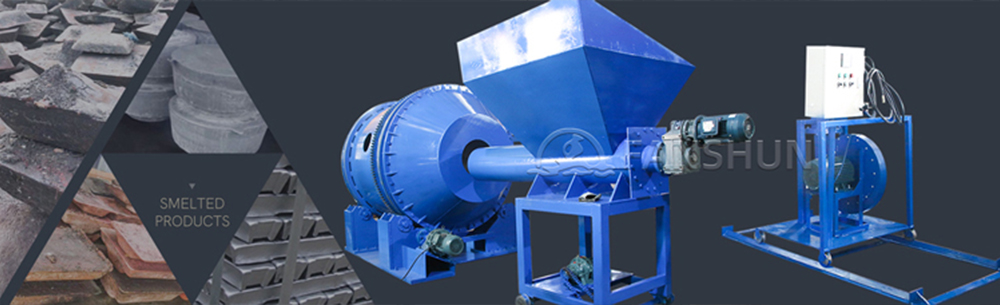

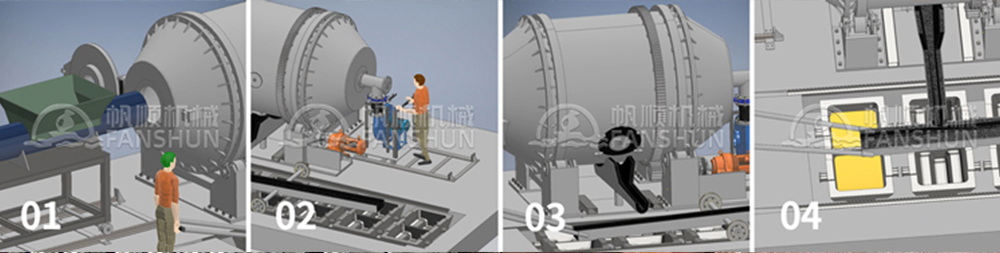

In modern metalworking industries, the efficient production of molten metals relies on a variety of specialized equipment, including the Rotary Melt furnace equipment, tilting rotary furnace, crucible tilting melting furnace, rotary furnace for aluminium melting, and rotary aluminum melting furnace. From the adaptable Rotary Melt furnace equipment to the precision of the tilting rotary furnace and crucible tilting melting furnace, each component plays a crucial role in the metal melting process, offering flexibility and reliability. The crucible tilting melting furnace and rotary aluminum melting furnace are both utilized for the melting of aluminum, offering efficient and versatile solutions for various industrial applications. Specifically engineered for aluminium melting, both the rotary furnace for aluminium melting and the rotary aluminum melting furnace utilize rotating mechanisms to guarantee thorough and uniform melting, meeting the exacting standards of modern metalworking industries. |