Copper Tube Drawing Machine: How Does It Craft Precision in Every Pipe?

In the world of metalworking and manufacturing, precision is paramount. Among the many machines that contribute to this precision, the Copper Tube Drawing Machine stands out as a critical piece of equipment. This machine, along with its counterparts like the Copper Tube Stretching Machine, Copper Tube Wire Drawing Machine, Copper Tube Stretching Equipment, and Copper Tube Wire Drawing Equipment, plays a vital role in shaping copper tubes with unmatched accuracy and consistency. But how exactly does it achieve this level of precision? Let’s dive into the fascinating world of copper tube manufacturing.

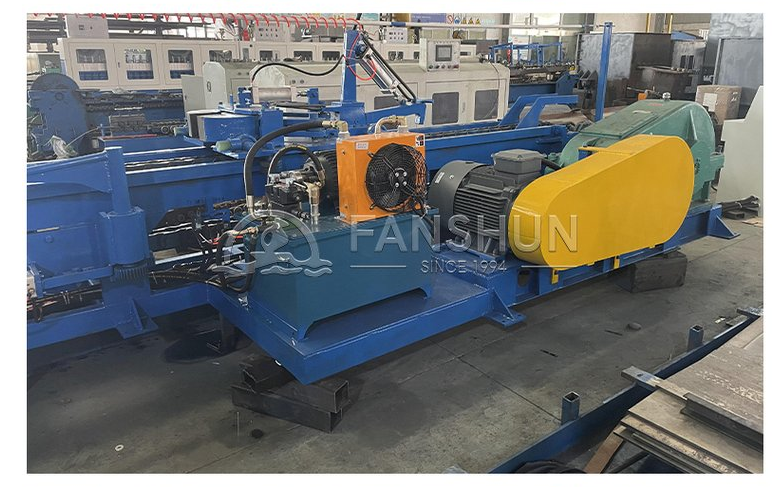

The Role of the Copper Tube Drawing Machine

The Copper Tube Drawing Machine is the backbone of copper tube production. It is designed to transform raw copper materials into perfectly shaped tubes with precise dimensions. The process involves pulling a copper billet or pre-formed tube through a series of dies to reduce its diameter and achieve the desired thickness. This machine ensures that every pipe meets strict quality standards, making it indispensable in industries such as HVAC, plumbing, and refrigeration.

What sets the Copper Tube Drawing Machine apart is its ability to maintain uniformity across long lengths of tubing. Whether it’s for small-diameter tubes used in medical equipment or larger pipes for industrial applications, this machine delivers consistent results. Its advanced control systems and precision-engineered components ensure that each tube is crafted to exact specifications.

The Complementary Role of the Copper Tube Stretching Machine

While the Copper Tube Drawing Machine focuses on reducing diameter and wall thickness, the Copper Tube Stretching Machine takes the process a step further. This equipment is used to elongate the copper tubes, ensuring they meet specific length requirements without compromising their structural integrity. The stretching process also enhances the mechanical properties of the copper, making it more durable and resistant to stress.

The Copper Tube Stretching Machine works in tandem with the drawing machine to produce tubes that are not only precise in diameter but also in length. This synergy between the two machines is crucial for applications where dimensional accuracy is critical, such as in the automotive and aerospace industries.

Precision Redefined: The Copper Tube Wire Drawing Machine

For applications requiring even finer dimensions, the Copper Tube Wire Drawing Machine comes into play. This specialized equipment is designed to produce ultra-thin copper tubes and wires, often used in electronics and telecommunications. The machine achieves this by drawing the copper through progressively smaller dies, resulting in tubes with diameters as small as a fraction of a millimeter.

The Copper Tube Wire Drawing Machine is a testament to the advancements in metalworking technology. Its ability to produce such fine tubes with high precision has revolutionized industries that rely on miniaturized components. From circuit boards to fiber optics, the applications of these finely drawn tubes are virtually limitless.

The Importance of Copper Tube Stretching Equipment

In addition to the drawing and wire drawing machines, Copper Tube Stretching Equipment plays a crucial role in the production process. This equipment is used to ensure that the tubes maintain their shape and dimensions during the stretching process. By applying controlled tension, the Copper Tube Stretching Equipment prevents defects such as warping or uneven thickness, which could compromise the quality of the final product.

The integration of Copper Tube Stretching Equipment into the production line enhances the overall efficiency of the manufacturing process. It allows manufacturers to produce longer tubes with consistent quality, reducing waste and improving productivity.

The Versatility of Copper Tube Wire Drawing Equipment

Finally, the Copper Tube Wire Drawing Equipment deserves special mention for its versatility. This equipment is capable of handling a wide range of copper alloys, each with its unique properties and applications. Whether it’s pure copper for electrical wiring or copper-nickel alloys for marine applications, the Copper Tube Wire Drawing Equipment ensures that every tube meets the required specifications.

The adaptability of the Copper Tube Wire Drawing Equipment makes it a valuable asset in industries that demand high-performance materials. Its ability to process different alloys with precision has opened up new possibilities for innovation in fields such as renewable energy and advanced electronics.

Conclusion

The Copper Tube Drawing Machine, along with the Copper Tube Stretching Machine, Copper Tube Wire Drawing Machine, Copper Tube Stretching Equipment, and Copper Tube Wire Drawing Equipment, represents the pinnacle of precision engineering in metalworking. These machines work together to produce copper tubes that meet the highest standards of quality and performance. From HVAC systems to cutting-edge electronics, the impact of these machines is felt across a wide range of industries.

As technology continues to evolve, so too will the capabilities of these remarkable machines. With their ability to craft precision in every pipe, they are shaping the future of manufacturing and paving the way for new innovations. Whether it’s through the Copper Tube Drawing Machine or the Copper Tube Wire Drawing Equipment, one thing is clear: precision is not just a goal—it’s a guarantee.