Title: Technological Breakthroughs in Horizontal Continuous Casting Machines: A New Era for Manufacturing

In recent years, the manufacturing sector has witnessed remarkable advancements in various technologies, particularly in the realm of horizontal continuous casting machines. These innovations not only enhance production efficiency but also contribute to improved product quality, making horizontal casting machines indispensable in modern manufacturing processes.

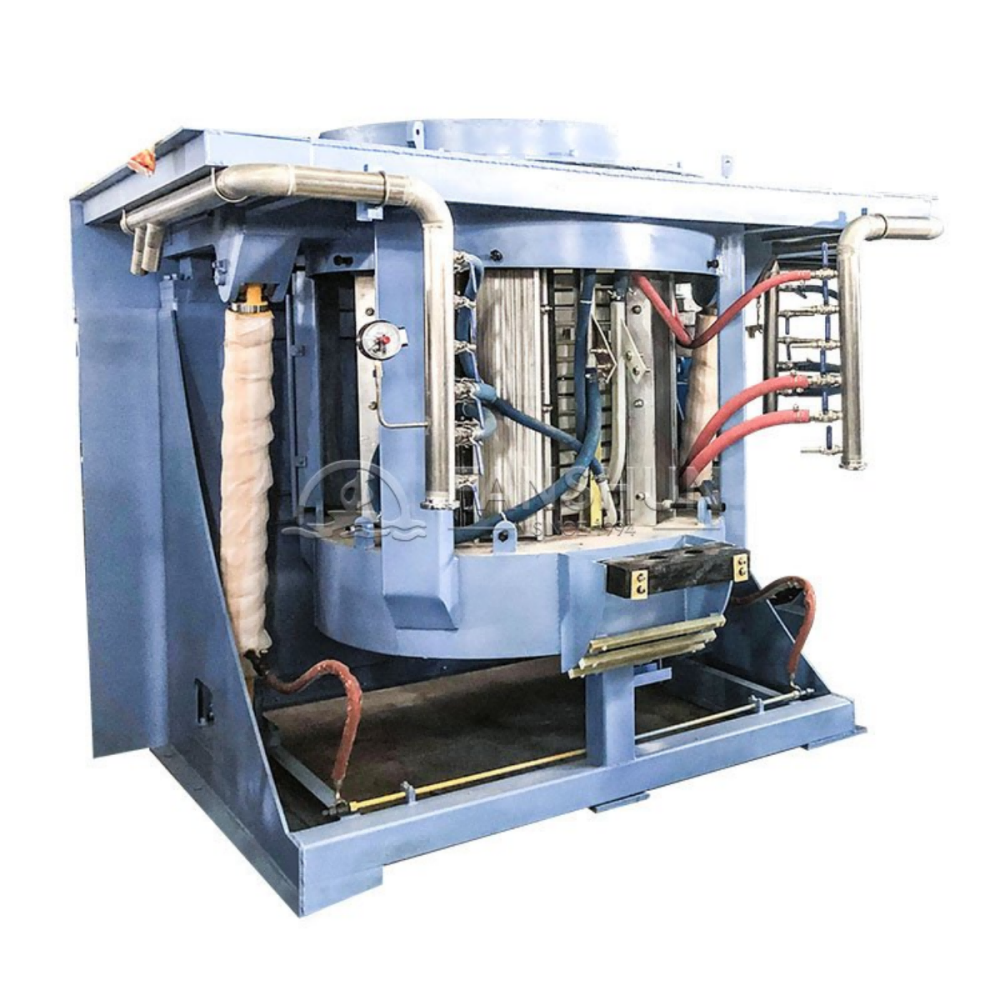

Horizontal continuous casting machines are designed to convert molten metal into solid metal forms through a continuous casting process. This method has gained popularity due to its ability to produce high-quality products with minimal waste. The technological breakthroughs in horizontal casting machines have been driven by several factors, including the demand for higher production rates and the need for greater flexibility in manufacturing processes.

One significant development is the improvement in automation within horizontal casting lines. Manufacturers are increasingly adopting advanced automation technologies that enable real-time monitoring and control of the casting process. These systems ensure optimal temperature control, precise pouring, and continuous feedback on product quality. As a result, the efficiency of horizontal continuous casting equipment has significantly increased, allowing for higher throughput and reduced operational costs.

Moreover, advancements in materials science have played a crucial role in enhancing the performance of horizontal casting machines. The use of high-performance alloys and innovative coatings has improved the durability of casting molds, reducing wear and tear and extending their operational lifespan. This has led to fewer interruptions in production and lower maintenance costs, making horizontal continuous casting machines more economically viable.

Another notable breakthrough is the integration of data analytics and artificial intelligence into horizontal continuous casting machines. These technologies enable manufacturers to analyze vast amounts of data generated during the casting process. By leveraging predictive analytics, companies can anticipate potential issues before they arise, allowing for proactive maintenance and minimizing downtime. This not only enhances the reliability of horizontal casting systems but also optimizes overall production efficiency.

The environmental impact of manufacturing processes is another area where technological advancements in horizontal continuous casting equipment have made significant strides. New energy-efficient designs and technologies are being implemented to reduce energy consumption and lower emissions during the casting process. This aligns with the growing global emphasis on sustainability and responsible manufacturing practices.

Furthermore, innovations in the design of horizontal casting lines have enabled manufacturers to achieve greater flexibility in their operations. Modern horizontal continuous casting machines can accommodate a wider range of materials and sizes, allowing for the production of various metal products without the need for extensive reconfiguration. This adaptability is essential in today's fast-paced manufacturing environment, where customer demands can change rapidly.

As we look to the future, the development of horizontal continuous casting machines is expected to continue evolving. Research and development efforts are focused on further enhancing the efficiency and sustainability of these systems. Emerging technologies, such as additive manufacturing and hybrid casting processes, are being explored to complement traditional casting methods, opening new avenues for innovation.

In conclusion, the advancements in horizontal continuous casting machines represent a significant leap forward for the manufacturing industry. With improved automation, enhanced materials, and the integration of data analytics, horizontal casting machines are poised to play a critical role in meeting the demands of modern production. As manufacturers embrace these technological breakthroughs, the future of horizontal continuous casting equipment looks promising, paving the way for increased efficiency, reduced environmental impact, and greater flexibility in manufacturing processes.

The ongoing commitment to innovation in horizontal casting machines will undoubtedly shape the landscape of manufacturing for years to come, making it an exciting time for industry stakeholders and end-users alike.