Industrial smelting and casting rotary furnaces differ from other types of furnaces in several key ways. Below are the main differences:

1. Design and Structure

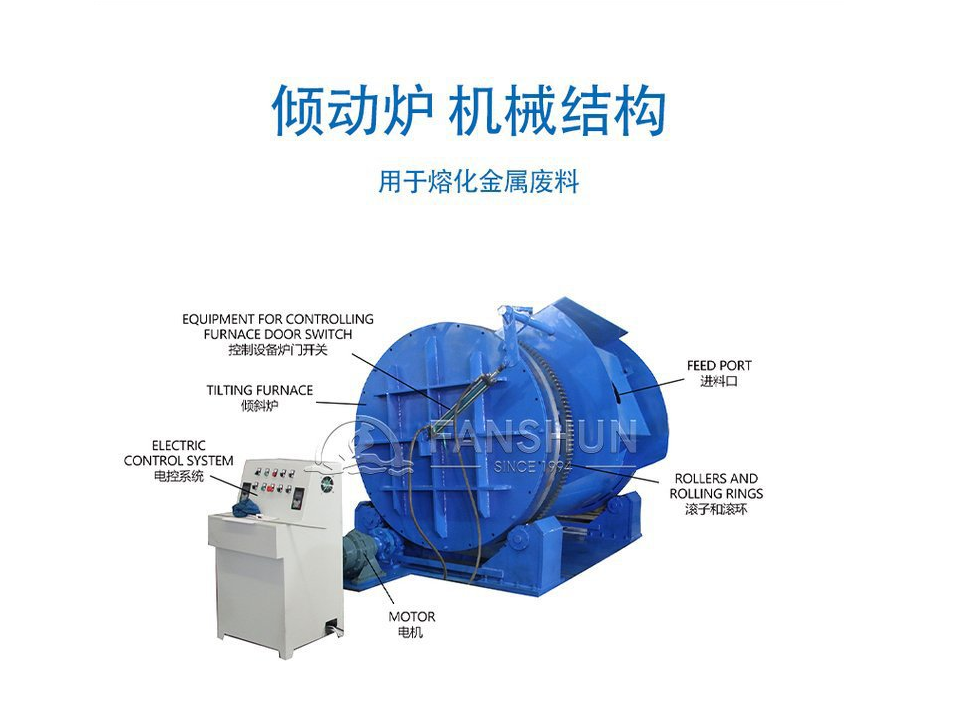

Rotary Furnaces: These are cylindrical furnaces that rotate around a central axis. This rotation allows the material inside to continuously mix and tumble, which leads to more uniform heating and melting.

Other Furnaces (such as electric arc furnaces, crucible furnaces, induction furnaces, etc.): These are typically stationary, with the material remaining in place once inside. Mixing may be achieved through gas injection, mechanical stirring, or other methods.

2. Heating Efficiency

Rotary Furnaces: The rotation and tumbling of materials improve heat transfer efficiency, making these furnaces particularly suitable for smelting metals with impurities or for recycling non-ferrous metals. The continuous motion helps prevent the formation of hotspots and ensures uniform melting.

Other Furnaces: For example, induction furnaces use electromagnetic induction to generate heat directly within the metal, which is highly efficient for melting high-purity metals quickly. Electric arc furnaces use an electric arc to generate heat, which is suitable for large-scale steel production.

3. Applications

Rotary Furnaces: Commonly used for smelting scrap metals with impurities (e.g., aluminum scrap, copper scrap) and for metal recycling. The rotating design is advantageous for mixing and separating impurities, making them ideal for the recycling industry.

Other Furnaces: Induction furnaces are better suited for rapid heating and refining of non-ferrous metals and steel. Electric arc furnaces are predominantly used for steelmaking in large-scale industrial settings.

4. Operation and Control

Rotary Furnaces: Require precise control of rotation speed, tilt angle, and heat input to optimize the smelting process. The rotating mechanism increases the complexity of operation and maintenance.

Other Furnaces: Induction furnaces and electric arc furnaces are generally simpler to operate, mainly involving power control and electromagnetic regulation to adjust heating intensity.

5. Energy Consumption and Environmental Impact

Rotary Furnaces: Often use natural gas, heavy oil, or pulverized coal as fuel, which can result in higher energy consumption. However, the rotating motion helps reduce harmful gas emissions and enhances smelting efficiency.

Other Furnaces: Induction and electric arc furnaces primarily use electricity, which can be more energy-efficient and result in lower pollution compared to fuel-based furnaces.

6. Cost and Maintenance

Rotary Furnaces: Typically have a more complex design and higher initial investment costs. However, they are versatile and can handle a wide range of raw materials. Maintenance mainly involves repairing and replacing refractory linings.

Other Furnaces: Furnaces like crucible and induction types have relatively lower initial costs but are limited in their applications. Maintenance needs are generally focused on electrical components and the crucibles themselves.

Summary

Rotary furnaces excel in handling materials with impurities and providing uniform heating and mixing, making them ideal for metal recycling and smelting applications. Other types of furnaces, like induction and electric arc furnaces, have their own strengths, particularly in refining high-purity metals, rapid heating, and large-scale steel production. Each type of furnace serves specific needs depending on the nature of the material and the desired outcome.