What are the characteristics of different types of furnaces?

In the realm of metal processing and manufacturing, Electric Arc Furnace, Die Casting Furnace, Scrap Metal Aluminum Melting Furnace, Crucible Furnace, High-Temperature Box Resistance Furnace, and Die Cast Natural Gas Furnace are employed to cater to specific melting and casting needs. The Electric Arc Furnace, Die Casting Furnace, Scrap Metal Aluminum Melting Furnace, Crucible Furnace, High-Temperature Box Resistance Furnace, and Die Cast Natural Gas Furnace stand out for their distinctive features and applications. This article delves into the characteristics, advantages, and applications of these furnaces, offering a comprehensive understanding of their roles in modern metallurgy.

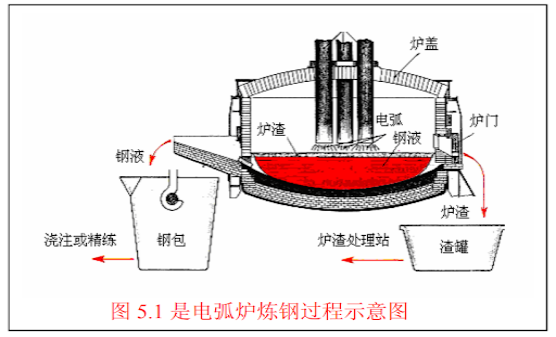

Electric Arc Furnace

The Electric Arc Furnace (EAF) is a pivotal tool in the steel industry, known for the Electric Arc Furnace efficiency and versatility in producing steel from scrap metal or direct reduced iron. The primary mechanism of the Electric Arc Furnace involves the use of electric arcs to generate the necessary heat for melting the metal. Electrodes are inserted into the furnace, and an electric current is passed through them, creating arcs that generate intense heat.

Characteristics:

1. High Efficiency: Electric Arc Furnaces are highly efficient in energy consumption, particularly when recycling scrap steel. They offer a significant advantage in terms of reduced energy use compared to traditional blast furnaces.

2. Flexibility: Electric Arc Furnaces can process a wide range of scrap materials and are adaptable to different types of steel production.

3. Environmental Impact: Modern Electric Arc Furnaces are designed to minimize emissions and improve environmental performance, aligning with industry regulations and sustainability goals.

Applications: The Electric Arc Furnace is primarily used for steelmaking, including the production of carbon steel, alloy steel, and stainless steel. It is favored for the Electric Arc Furnace’s ability to produce high-quality steel with minimal impurities.

Die Casting Furnace

The Die Casting Furnace is essential in the production of precision metal parts used in various industries, including automotive, aerospace, and consumer goods. Die casting involves forcing molten metal into a mold cavity under high pressure, allowing for the creation of complex shapes with fine details.

Characteristics:

1. Temperature Control: Die Casting Furnaces are equipped with precise temperature control systems to ensure consistent metal quality and minimize defects.

2. High Throughput: Die Casting Furnaces are designed for high production rates, making them suitable for manufacturing large quantities of parts in a short period.

3. Material Versatility: Die Casting Furnaces can handle a range of non-ferrous metals, including aluminum, zinc, and magnesium alloys.

Applications: Die Casting Furnaces are used for producing high-volume, precision parts such as engine components, housings, and fittings. The ability to achieve tight tolerances and complex geometries makes Die Casting Furnaces indispensable in modern manufacturing.

Scrap Metal Aluminum Melting Furnace

The Scrap Metal Aluminum Melting Furnace is specifically designed for melting aluminum scrap and producing molten aluminum for further processing. This type of the Scrap Metal Aluminum Melting Furnace is crucial for recycling aluminum, which is both economically beneficial and environmentally friendly.

Characteristics:

1. Energy Efficiency: The Scrap Metal Aluminum Melting Furnaces are engineered to maximize energy efficiency, often utilizing advanced technologies to recover and reuse heat.

2. Contaminant Management: The Scrap Metal Aluminum Melting Furnace ’ s Effective management systems are in place to handle contaminants in scrap aluminum, ensuring the production of high-quality molten metal.

3. Temperature Precision: The Scrap Metal Aluminum Melting Furnace maintain precise temperatures,which is essential for optimal aluminum melting and alloying.

Applications: The Scrap Metal Aluminum Melting Furnace is used primarily in aluminum recycling facilities. The Scrap Metal Aluminum Melting Furnaces produce molten aluminum for casting into ingots, billets, or other forms. The ability of the Scrap Metal Aluminum Melting Furnace is recycle aluminum scrap,which helps reduce the overall environmental impact and lower production costs.

Crucible Furnace

The Crucible Furnace is a versatile melting device used for small to medium-scale metal processing. The Crucible Furnace employs a crucible, a container capable of withstanding high temperatures, to melt metals. The Crucible Furnace is commonly used in laboratories, small foundries, and specialized applications.

Characteristics:

1. Compact Design: Crucible Furnaces are typically smaller in size, making them suitable for operations with limited space or lower production volumes.

2. Variety of Fuels: Crucible Furnaces can be powered by electricity, gas, or other fuel sources, offering flexibility based on operational requirements.

3. Precision Melting: Crucible Furnaces are designed for precise control over the melting process, allowing for the production of high-quality metal alloys.

Applications: Crucible Furnaces are used for melting various metals, including precious metals, ferrous and non-ferrous alloys. Crucible Furnaces are often employed in jewelry making, small-scale casting, and experimental metal processing.

High Temperature Box Resistance Furnace

The High Temperature Box Resistance Furnace is a specialized furnace designed for applications requiring extremely high temperatures. The High Temperature Box Resistance Furnace utilizes electrical resistance heating elements to achieve and maintain the high temperatures needed for certain industrial processes.

Characteristics:

1. Temperature Range: Capable of reaching temperatures well above those of standard resistance furnaces, making the High Temperature Box Resistance Furnace suitable for processes such as sintering, ceramics, and advanced material processing.

2. Uniform Heating: The design of the High Temperature Box Resistance Furnace ensures uniform heating across the furnace chamber, which is crucial for consistent material properties.

3. Controlled Environment: The High Temperature Box Resistance Furnace often equipped with advanced control systems to manage temperature and atmosphere within the furnace.

Applications: The High Temperature Box Resistance Furnace is used in high temperature applications such as materials testing, advanced ceramics production, and semiconductor fabrication. The High Temperature Box Resistance Furnace is essential for processes that require precise temperature control and a stable environment.

Die Cast Natural Gas Furnace

The Die Cast Natural Gas Furnace is a type of furnace used in the die casting process, where natural gas serves as the primary fuel source. The Die Cast Natural Gas Furnace is particularly valued for its efficiency and cost-effectiveness in heating.

Characteristics:

1. Fuel Efficiency: The Die Cast Natural Gas Furnace use natural gas, which is often more cost-effective and cleaner than other fossil fuels, results in lower operational costs and reduced emissions.

2. Rapid Heating: The Die Cast Natural Gas Furnace provides rapid heating capabilities, which is advantageous in maintaining high productivity levels in die casting operations.

3. Environmental Considerations: The Die Cast Natural Gas Furnace of natural gas burns cleaner than other fuels, contributing to a reduction in greenhouse gas emissions.

Applications: The Die Cast Natural Gas Furnace is Primarily used in die casting operations where high temperatures are required to melt non-ferrous metals. The Die Cast Natural Gas Furnace’s efficiency and cleaner fuel make it a preferred choice for many manufacturers.

Conclusion

Each type of furnace discussed plays a crucial role in the metal processing industry, offering unique benefits tailored to specific applications. The Electric Arc Furnace excels in steel production, while the Die Casting Furnace and Scrap Metal Aluminum Melting Furnace are vital for precise metal casting and recycling. The Crucible Furnace serves small-scale and specialized needs, whereas the High-Temperature Box Resistance Furnace meets the demands of high-temperature processes. Finally, the Die Cast Natural Gas Furnace combines efficiency and environmental considerations for modern manufacturing.

Understanding the characteristics and applications of these furnaces enables manufacturers to select the most appropriate equipment for their needs, optimizing performance and achieving desired outcomes in metal processing and casting.