In the realm of manufacturing and industrial production, one critical piece of equipment that plays a central role is the drawing machine. Often overlooked but essential to many sectors, especially in electronics and telecommunications, a drawing machine is responsible for shaping materials such as copper wire into precise sizes and forms. This article delves into the intricacies of the copper wire drawing machine, highlighting the technology, its role in the production line, and how it connects to other critical equipment like the Copper wire production line, Copper wire processing machine, Copper wire pulling machine, and Wire drawing mill.

Understanding the Drawing Machine

At its core, a drawing machine is a device used to stretch metal, like copper, to reduce its cross-sectional diameter without affecting its volume. The Copper wire drawing equipment specifically deals with the production of fine copper wires, which are critical in numerous industries such as telecommunications, automotive, and electronics. By controlling the tension and applying force, the drawing machine ensures that the wire achieves the desired thickness and consistency, ready for further stages of production.

The Role of the Copper Wire Drawing Machine

A Copper wire drawing machine is typically a part of a larger Copper wire production line, which includes several other machines like the Copper wire pulling machine and Copper wire processing machine. These machines work in synergy to convert raw copper into a finished product. Here’s how each fits into the process:

Copper wire pulling machine: This machine pulls the copper rod through a series of dies, reducing the diameter in stages until it reaches the desired thickness. The copper is drawn by force through the dies, maintaining uniformity throughout the process. The Copper wire pulling machine is critical in reducing the size of the copper rod while preserving its properties.

Copper wire processing machine: Once the copper wire has been drawn to the appropriate size, it moves to the Copper wire processing machine. This equipment helps in preparing the wire for various applications, including insulating, cutting, or coiling. The Copper wire processing machine is designed to ensure that the copper wire is of the highest quality and ready for use in electronics, electrical cables, or other industrial applications.

Wire drawing mill: The Wire drawing mill is the facility where the entire wire drawing process takes place. In this mill, large copper rods are transformed into fine wire through a series of drawing machines. The mill is equipped with multiple Copper wire drawing equipment, each contributing to a different stage of the wire reduction process. The Wire drawing mill is crucial for maintaining the operational efficiency of the production line.

How Copper Wire Drawing Equipment Works

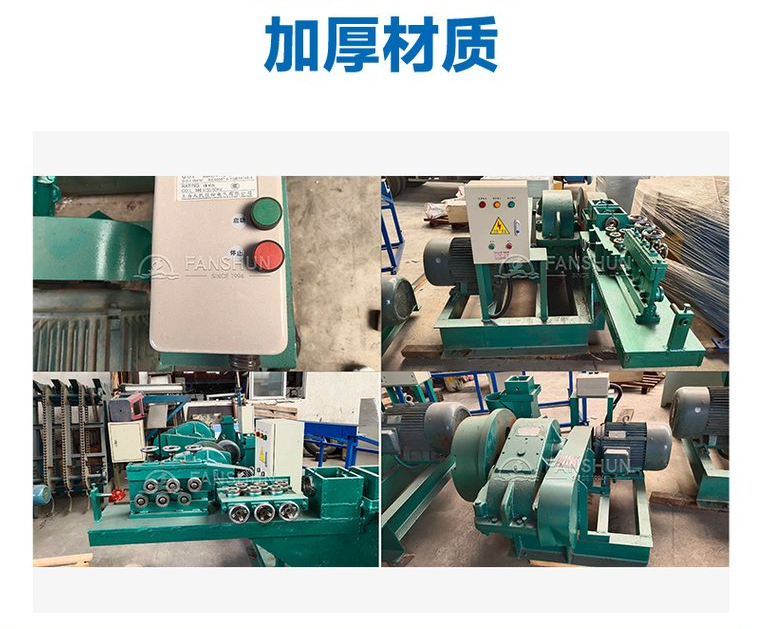

The Copper wire drawing equipment is typically composed of several key components, including a capstan, dies, and lubrication systems. The capstan applies tension to pull the wire through the dies, which gradually reduce the diameter of the copper. The lubrication system ensures that the friction between the wire and the dies is minimized, preventing damage to the copper during the drawing process. By controlling the speed and tension of the capstan, the Copper wire drawing machine can produce wires of various diameters.

Moreover, advanced Copper wire drawing equipment often includes features that allow for real-time monitoring and adjustment, ensuring that the wire meets the stringent standards required for industries like aerospace and telecommunications.

The Importance of the Copper Wire Production Line

The Copper wire production line is a highly integrated system designed to convert raw copper rods into finished copper wire. This production line typically includes several Copper wire pulling machines and Copper wire processing machines, as well as annealing and coiling stations. Each machine plays a vital role in ensuring that the wire meets the necessary specifications for its intended use.

For example, after the wire has been drawn to the correct size using the Copper wire pulling machine, it might pass through an annealing process where the copper is heated to reduce brittleness. Following this, the Copper wire processing machine can apply insulation or other treatments before the wire is finally coiled and prepared for shipping.

In the Wire drawing mill, the various machines operate in unison to ensure that the wire is produced efficiently and meets industry standards. This coordinated approach within the Copper wire production line ensures that the wire is ready for various industrial applications, including automotive wiring, power cables, and electronic components.

Innovations in Copper Wire Drawing Equipment

Over the years, Copper wire drawing equipment has evolved significantly, incorporating cutting-edge technology to improve efficiency and quality. Modern Copper wire pulling machines and Copper wire processing machines are equipped with sensors and automation systems that allow for precise control over the wire drawing process. This has led to faster production times, reduced waste, and higher-quality products.

In particular, the use of advanced materials for the dies in the Copper wire pulling machine has enhanced the durability of the equipment, allowing it to handle higher volumes of copper without degrading. Additionally, improvements in lubrication systems have reduced the friction between the copper wire and the dies, leading to a smoother drawing process and less wear on the machine components.

Challenges in Copper Wire Production

Despite the advances in technology, the copper wire drawing process is not without its challenges. One of the primary concerns is maintaining the quality and consistency of the copper wire throughout the production process. Any inconsistencies in the drawing process can lead to defects in the wire, which can result in failures when used in critical applications like electrical wiring or telecommunications cables.

To overcome these challenges, manufacturers invest heavily in maintaining and upgrading their Copper wire production line. Regular maintenance of the Copper wire drawing machine and Copper wire processing machine is essential to ensure that the equipment operates at peak efficiency. In addition, operators must be trained to monitor the wire drawing process closely and make adjustments as necessary to prevent defects.

Conclusion

The drawing machine is an essential piece of equipment in the copper wire industry, playing a crucial role in shaping raw copper into usable wire. It works in tandem with other machines, such as the Copper wire pulling machine and Copper wire processing machine, within the Wire drawing mill to ensure the efficient production of high-quality copper wire. As part of a larger Copper wire production line, the Copper wire drawing machine contributes to the creation of products that are integral to industries like telecommunications, electronics, and power transmission.

With continued advancements in technology, the future of copper wire production looks promising. The introduction of more automated systems and improved materials will likely enhance the efficiency and quality of copper wire manufacturing even further, ensuring that industries that rely on copper wire can continue to operate at the highest standards.