| Copper pipes are divided into two main series: brass pipes and copper pipes. The production process of copper pipe billets includes three methods: horizontal continuous casting, upward casting, and casting copper ingots followed by extrusion. For copper pipes, raw materials for purple copper pipes can be either cathode electrolytic copper or recycled copper scrap. They undergo processes of melting, insulation, continuous casting to produce billets, and then proceed with rolling, drawing, annealing, drawing again, and coiling (or straight pipe) production process. For brass pipes, raw materials can be cathode electrolytic copper plates with zinc ingots or recycled copper scrap. After melting (with composition adjustment) and testing to meet standards, the materials proceed to insulation, continuous casting to produce billets, and then undergo rolling (heating extrusion molding), drawing, annealing, pickling (surface oxide skin removal), drawing again, and finally straightening to achieve the finished product. |

Special shaped rod brass rod, renowned for their versatility and durability, are integral components in a myriad of industries, serving both functional and aesthetic purposes. These special shaped rod brass rod, meticulously crafted with precision, find widespread applications in electrical, architectural, and mechanical engineering endeavors. In the realm of electrical engineering, special shaped rod brass rod play a crucial role in the construction of wiring systems, ensuring efficient power transmission and conductivity. Meanwhile, in architectural design, these special shaped rod brass rod add a touch of elegance and sophistication, enhancing the visual appeal of structures through their intricate designs and finishes. Complementing the functionality of special shaped rod brass rod are essential materials such as copper pipes, aluminum ingot sow molds, copper ore, and aluminum strips. Copper pipes, prized for their corrosion resistance and thermal conductivity, are indispensable in plumbing systems, facilitating the seamless flow of fluids for various purposes. Aluminum ingot sow molds, crucial in the casting process,aluminum ingot sow mold enable the precise shaping and solidification of aluminum ingots, essential raw materials in industries ranging from automotive to aerospace. Aluminum ingot sow molds come in various shapes and sizes depending on the specific requirements of the aluminum casting process and the desired final product. Furthermore, copper ore, extracted through rigorous mining operations, serves as the primary source of copper, a vital element in electrical wiring, electronics, and construction materials. Copper ore refers to the naturally occurring rock or mineral from which copper metal can be extracted. Copper ore typically contains copper minerals, along with other elements such as sulfur, iron, and various impurities. Additionally, aluminum strips, valued for their lightweight nature and exceptional strength, find extensive use in packaging, construction, and transportation sectors, contributing to advancements in sustainable material usage and design innovation. Through their diverse applications and interconnected roles, special shaped rod brass rod, copper pipes, aluminum ingot sow molds, copper ore, and aluminum strips collectively underscore the indispensable role of metallurgical processes in shaping modern society's technological landscape and infrastructure development. |

3D Animation Preview

| More information about the 3D animation,please "contact us". |

Project Reference Equipment Configuration

| Furnace | Holding Furnace | Servo Continuous Casting Machine | Cutting Machine | Double Action Hydraulic Dispersing Machine | Heating Furnace |

| 120Kw | 75Kw | 5.5 Kw Double Bar | Double Bar | 1250T | Natura Gas |

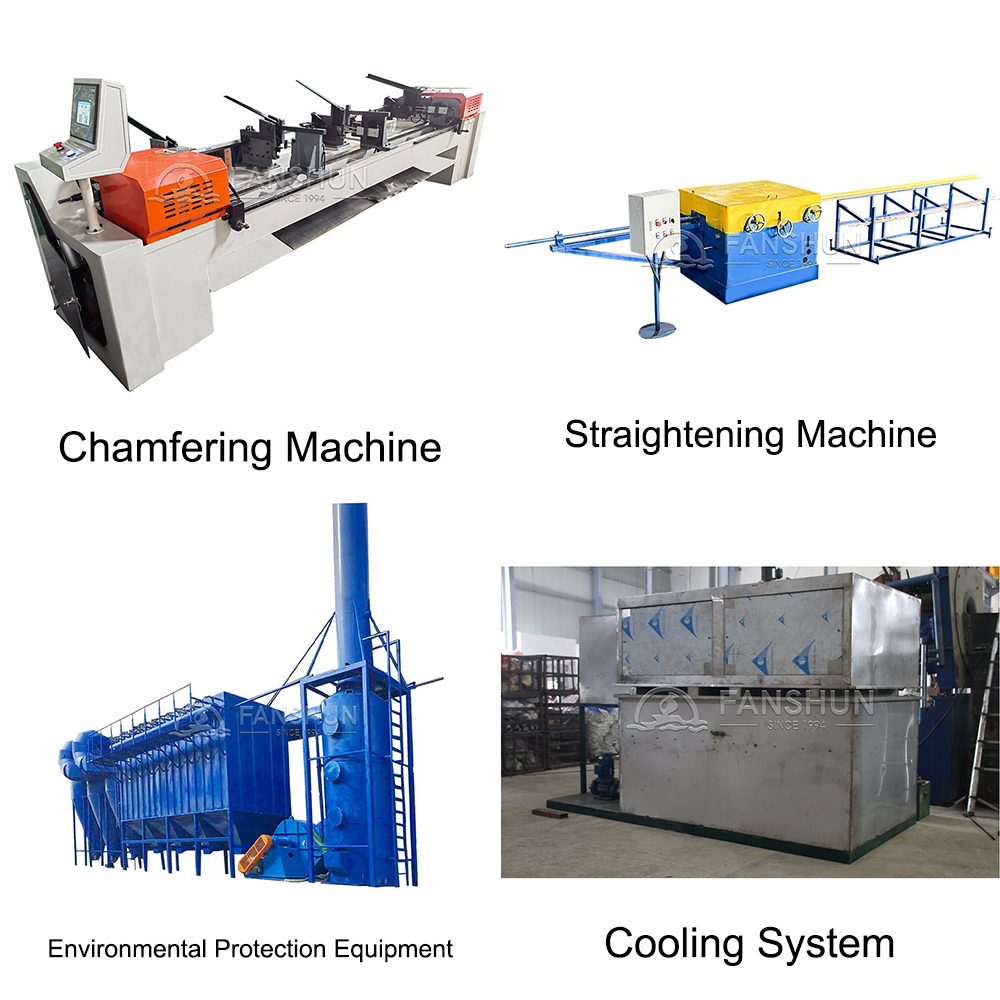

| Round Trip Cold Rolling Mill | Copper Tube Drawing Machine | Chamfering Machine | Straightening Machine | Environmental Protection Equipment | Cooling System |

| √ | 2 unit | √ | √ | 230# | Volumn:50T Water Storage:20T |

| (Please refer to the above equipment configuration for process flow.) |

Equipment Configuration Reference