| Aluminum Gravity Casting Production Process Aluminum gravity casting is a widely used method for producing high-quality aluminium profiles and aluminium products. Aluminum gravity casting is particularly valued for its ability to create intricate and durable components. Production Process and Working Principle: In aluminum gravity casting, molten aluminum is poured into a mold using the force of gravity, rather than high pressure. The aluminium profile mold, typically made of steel, is designed to shape the molten aluminum into the desired form. The aluminum fills the aluminium profile mold, cooling and solidifying into a solid aluminium product. After cooling, the aluminium profile mold is opened, and the aluminium product is removed for further processing, such as machining or finishing.Aluminum products are:electric heating plate, electric hot plate, hot plate stove and so on. Advantages: Cost-Effective: Aluminum gravity casting is more economical than other casting methods, especially for small to medium production runs. High Precision: The aluminum gravity casting process allows for the production of aluminium profiles and aluminium product with intricate details and smooth surfaces. Material Efficiency: The aluminum gravity casting process minimizes waste, as excess aluminum can be recycled back into the casting process.To produce valuable aluminum products:electric heating plate, electric hot plate, hot plate stove and so on. Applications: Aluminum gravity casting is commonly used to produce a variety of aluminium products, including components for electric heating plates and electric hot plates. Electric heating plates,electric hot plates and hot plate stoves , which are benefit from the durability and heat conductivity of cast aluminum. Electric heating plates,electric hot plates and hot plate stoves, which are also used in the automotive, aerospace, and construction industries, where strong and lightweight aluminium profiles are essential. In summary, aluminum gravity casting is a versatile and efficient method for producing high-quality aluminium profiles and aluminium products. Its ability to produce detailed components makes it ideal for applications in electric heating plates, electric hot plates, and hot plate stoves, among other industries. |

3D Animation Preview

| More information about the 3D animation,please "contact us". |

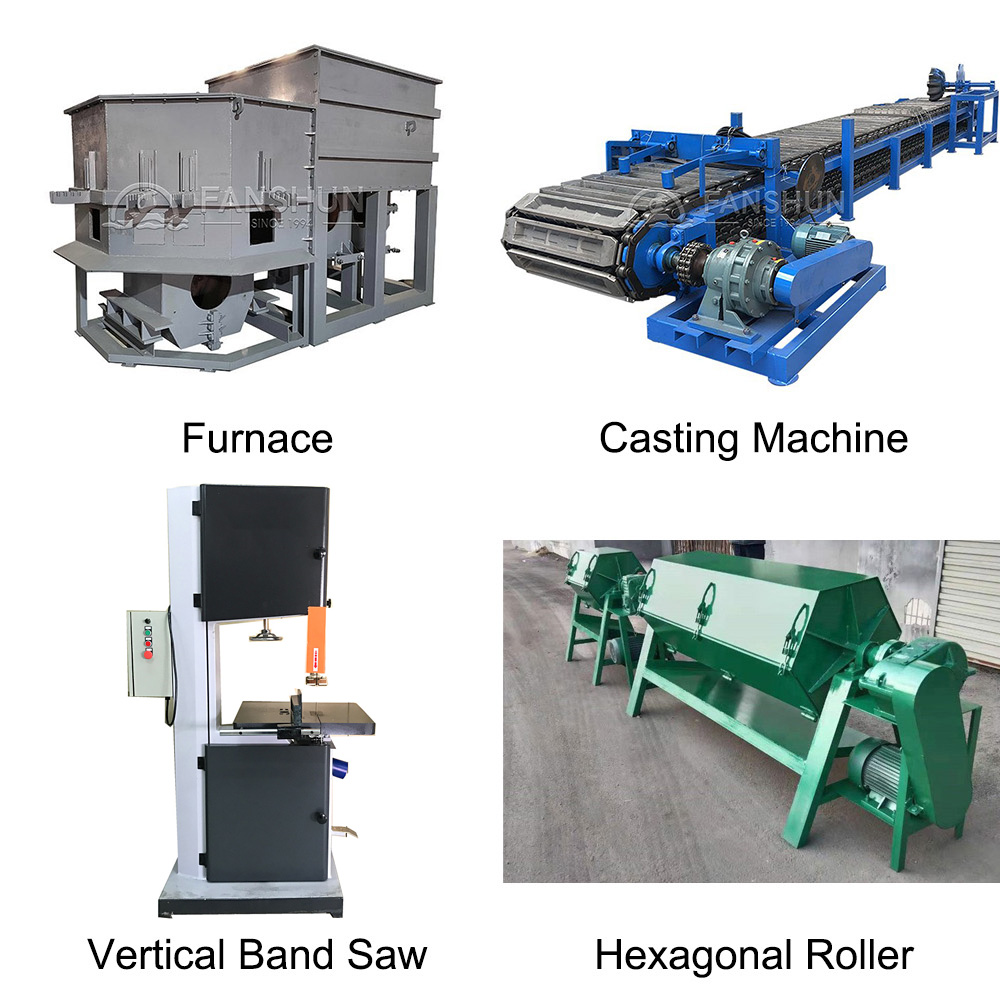

Equipment Configuration Reference

| Furnace | Casting Machine | Vertical Band Saw | Hexagonal Roller |

| (Please refer to the above equipment configuration for process flow.) |