The production process of copper bars involves sophisticated machinery such as the Copper bar horizontal continuous casting machine. Copper bar horizontal continuous casting machine ensures the efficient and uninterrupted casting of pure copper plates. Pure copper plates make them indispensable in a wide range of industries and applications.Through the Horizontal continuous casting line, these plates are meticulously processed, resulting in small copper plates of precise dimensions.Horizontal Continuous Casting Line facilitates continuous and efficient casting of metal billets or slabs, ensuring high-quality end products, flexibility in production, energy efficiency, and cost reduction for metal manufacturers.Up Casting machine production line further refines these plates, maintaining quality standards throughout the production process. |

3D Animation Preview

| More information about the 3D animation,please "contact us". |

Equipment Configuration Reference

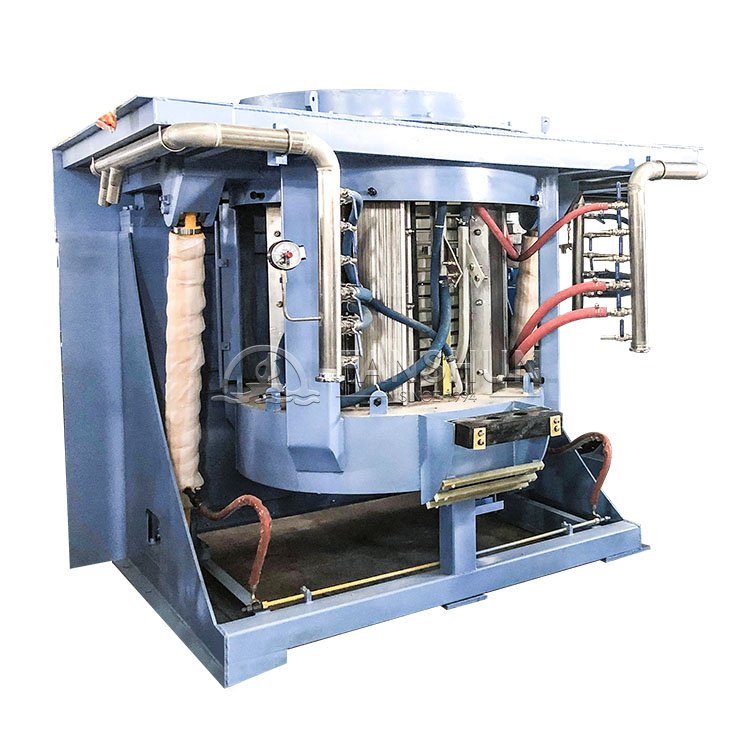

| Industrial Frequency Furnace |

| Downward Semi-Continuous Caster |

| The continuous casting machine for downward semi-continuous casting with copper molds. |

| Environmental Protection Equipment |

| Surface Milling Machine |

| Heating Machine |

| Hot Rolling Mill |

| Cold Rolling Mill |

| Cleaning Production Line |

| The semi-continuous casting billet prior to hot rolling for downward casting |