【video】

3D Animation Preview

| More information about the 3D animation,please "contact us". |

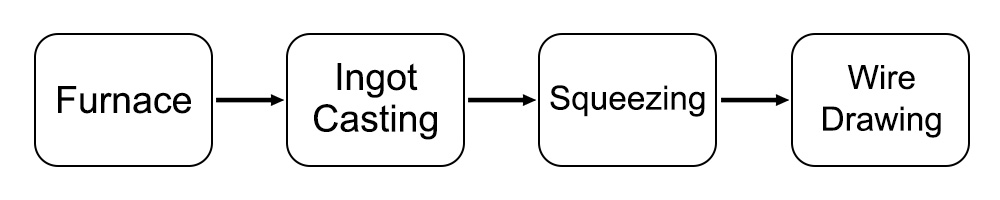

Production Process Flow

Aluminium Wire: Aluminium wire is prized for its lightweight nature, excellent conductivity, and corrosion resistance. There are several types of aluminum wire, including solid, stranded, and multi-strand wires, each tailored for specific uses in industries like electronics, power distribution, and aerospace. The versatility and reliability of aluminium wire make it a staple in modern manufacturing. Zinc Plated Wire: Zinc plated wire is another vital product of this production line, offering a strong base metal coated with a protective layer of zinc. Zinc plated wire is particularly valued in construction, automotive, and fencing applications for its superior corrosion resistance. The process of producing zinc plated wire involves advanced techniques to ensure consistent coating thickness and adherence. Aluminum MIG Wire: In welding, aluminum MIG wire plays a critical role. This type of aluminium wire is designed for use in Metal Inert Gas (MIG) welding, providing excellent weldability and strong, durable joints. Aluminum MIG wire is widely used in the automotive and aerospace industries, where lightweight yet robust connections are essential. Production Wire Equipment: The success of Zinc-Aluminium Wire Production No.2 relies heavily on sophisticated production wire equipment. Machines such as wire drawing systems, annealing equipment, and coating machines are integral to the process. This production wire equipment ensures that aluminium wire, zinc-plated wire, and aluminum MIG wire are manufactured to the highest standards, meeting the specific requirements of each application. The process of Zinc-Aluminium Wire Production No.2 is therefore crucial in creating the diverse types of aluminum wire and zinc plated wire needed in today’s industries. These wires, produced using advanced production wire equipment, meet the rigorous demands for quality, precision, and performance. |