3D Animation Preview

| More information about the 3D animation,please "contact us". |

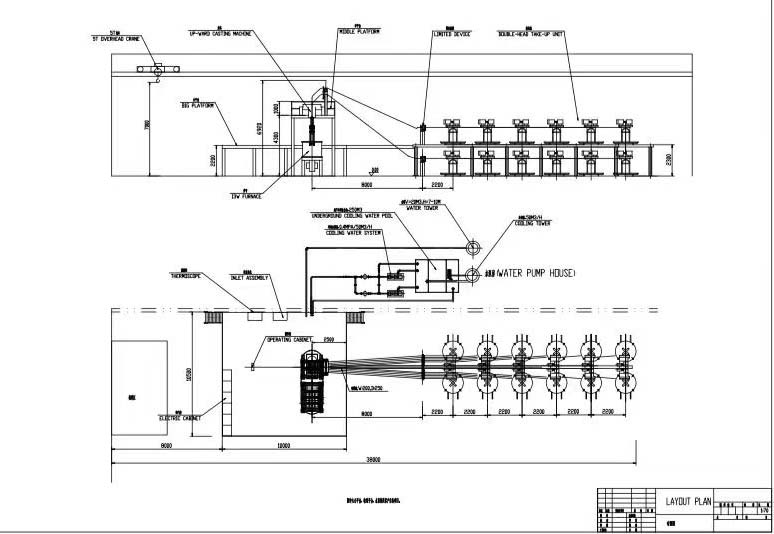

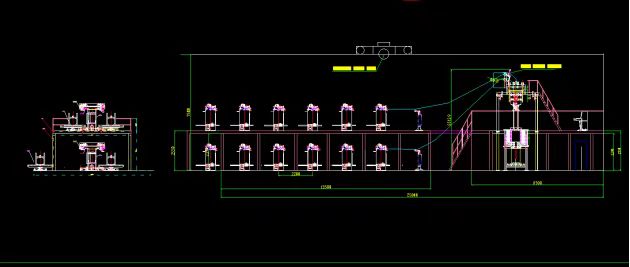

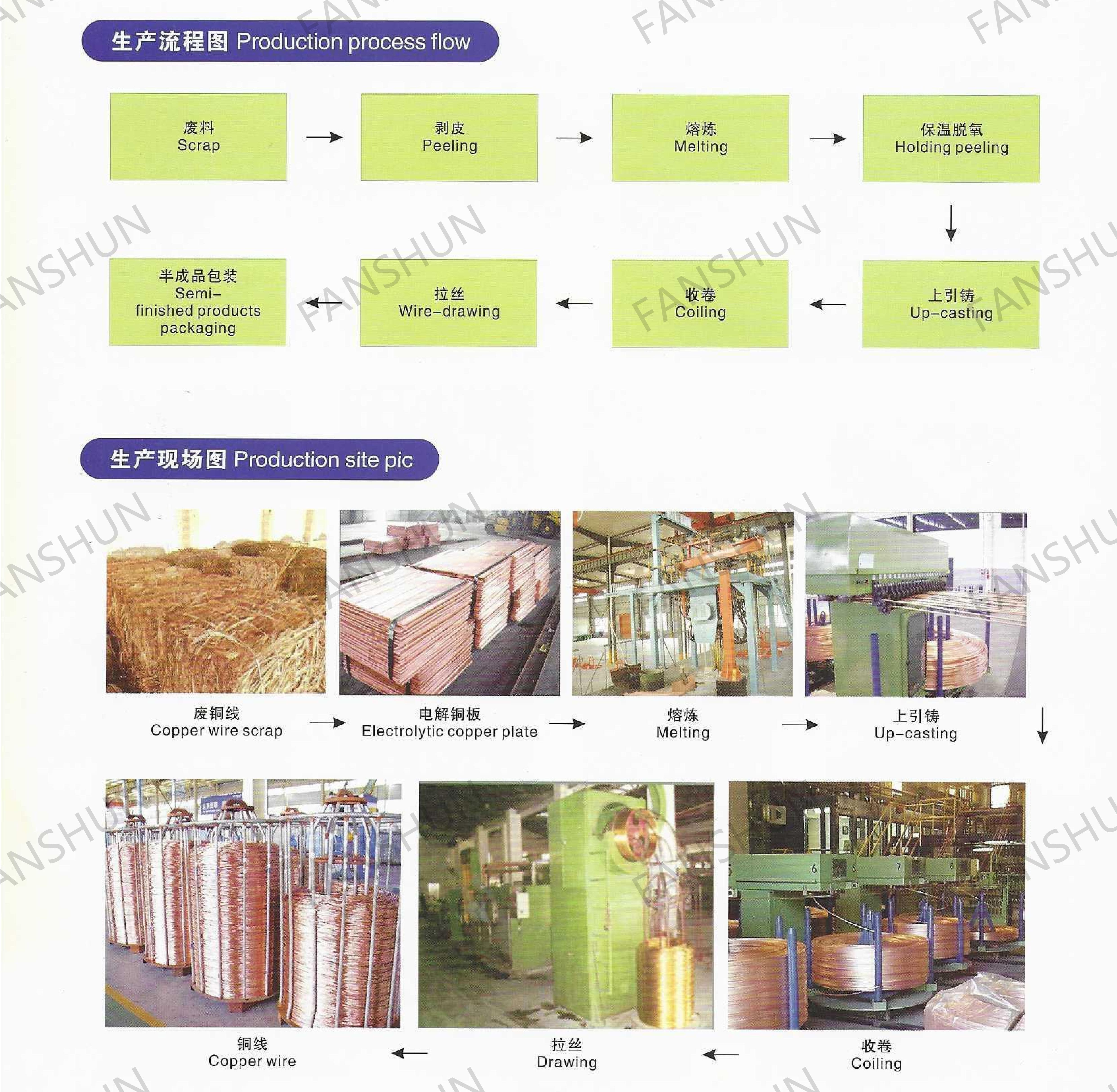

Casting 1000T Oxygen-Free Copper Rods from Copper Cathodes The process of casting 1000T oxygen free copper rods from copper cathodes is an advanced technique used to produce high-purity copper rods , copper wire and bronze rods. This method is crucial for ensuring the quality and performance of various copper rods copper wire, and bronze rods. Production Process and Working Principle: The production starts with melting copper cathodes in a furnace to create molten copper. This molten copper is then directed into the Oxygen Free Copper Rod Upcasting system. This system uses an upward casting technique, which allows the copper to solidify gradually in an oxygen-free environment, maintaining its purity. The equipment used are:two roll straightening machine, bar straightening press, and so on. Once the copper rods are cast, they are subjected to further processing to ensure they meet quality standards. A bar straightening press is used to correct any bending or warping in the rods. After this, a two roll straightening machine is employed to achieve precise straightening. This machine uses two rollers to apply pressure and ensure that the rods are perfectly straight and uniform. Advantages: High Purity: The Oxygen Free Copper Rod Upcasting process ensures that the copper rods maintain a high level of purity, essential for producing high-quality copper wire , bronze rod and other copper products. Consistency: The continuous casting and subsequent straightening processes, including the bar straightening press and the two roll straightening machine, ensure consistent quality and dimensions of the bronze rods and rods. Efficiency: The production process is efficient, minimizing waste and reducing the need for additional finishing. Applications: The 1000T oxygen-free copper rods are used in various applications where high-quality copper is required. These include the production of copper wire, bronze rods, and other copper-based materials. The rods are also essential in industries that require reliable and high-purity copper products for electrical and structural uses. In summary, casting 1000T oxygen-free copper rods from copper cathodes using the Oxygen Free Copper Rod Upcasting method ensures high purity and consistent quality. The process involves key equipment such as the bar straightening press and the two roll straightening machine to produce rods that are crucial for applications involving copper wire, bronze rods, and other essential copper products. The key words used in this article are:copper wire, two roll straightening machine, bar straightening press, bronze rod ,Oxygen Free Copper Rod Upcasting. |

Project Reference Equipment Configuration

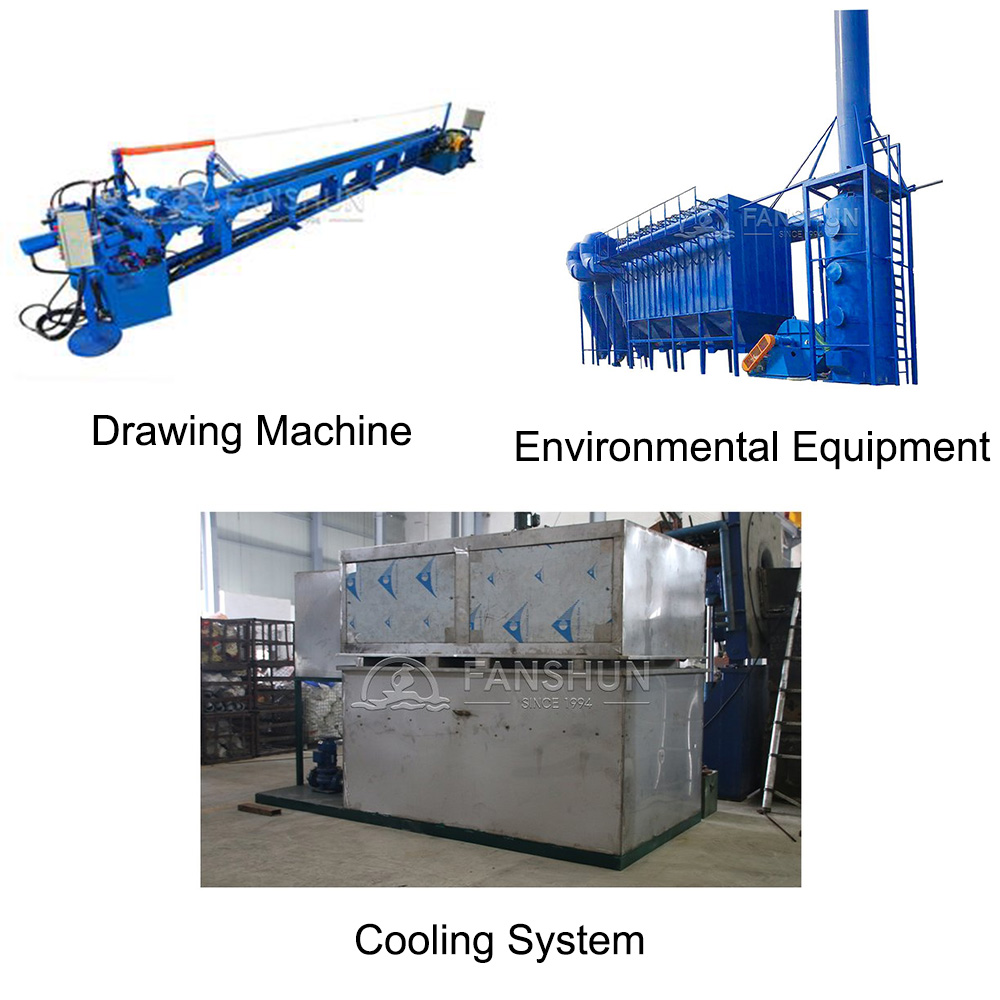

| Furnace | Holding Furnace | Up-Casting Machine | Coiling Machine | Drawing Machine | Environmental Equipment | Cooling System |

| 180Kw+180Kw | 180Kw | 24 heads | 12 units 24plates | φ3-8mm | 300# Bag 30Kw Ventilator | Volumn:200T Water Storage:30T |

Equipment Configuration Reference