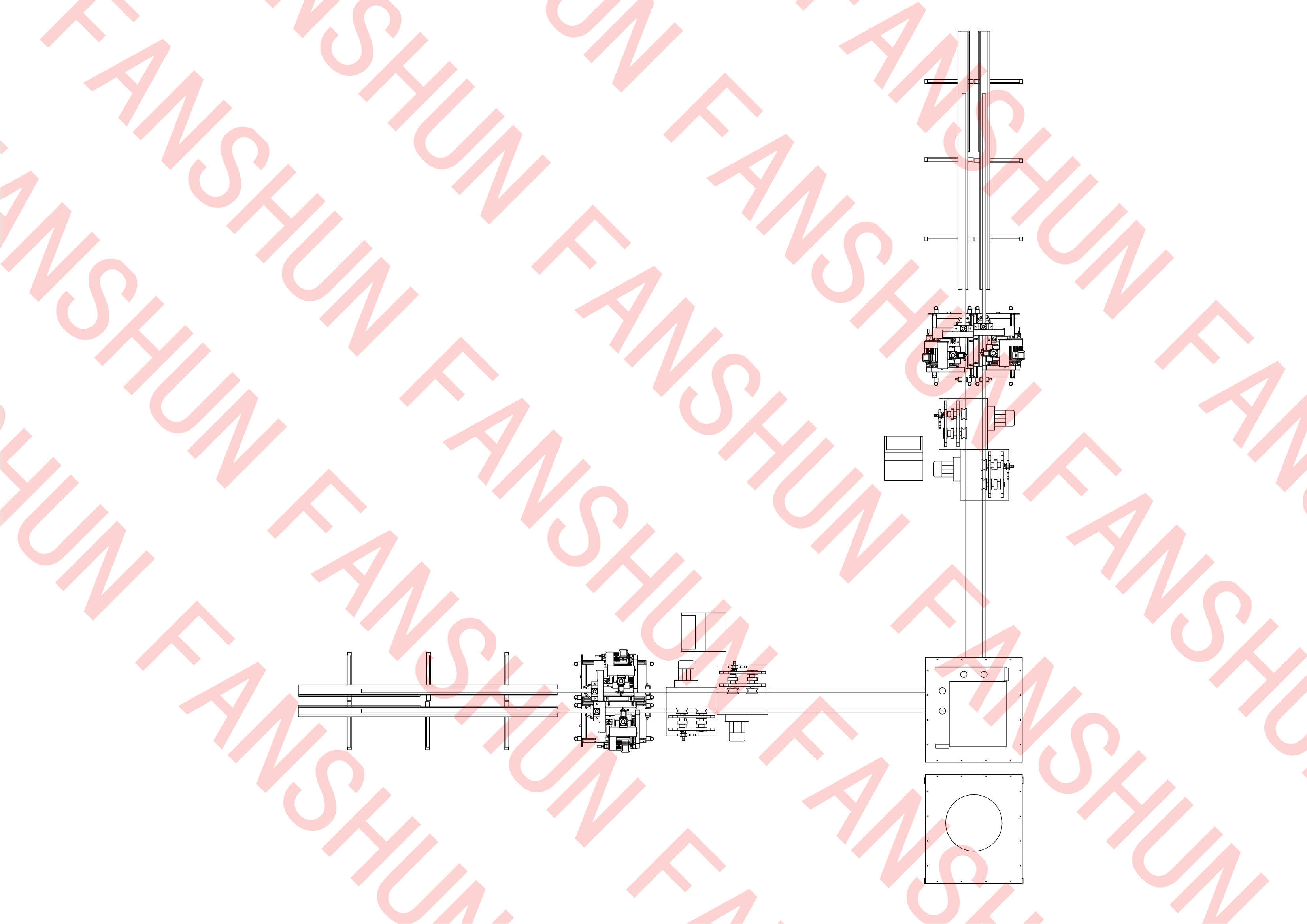

3D Animation Preview

| More information about the 3D animation,please "contact us". |

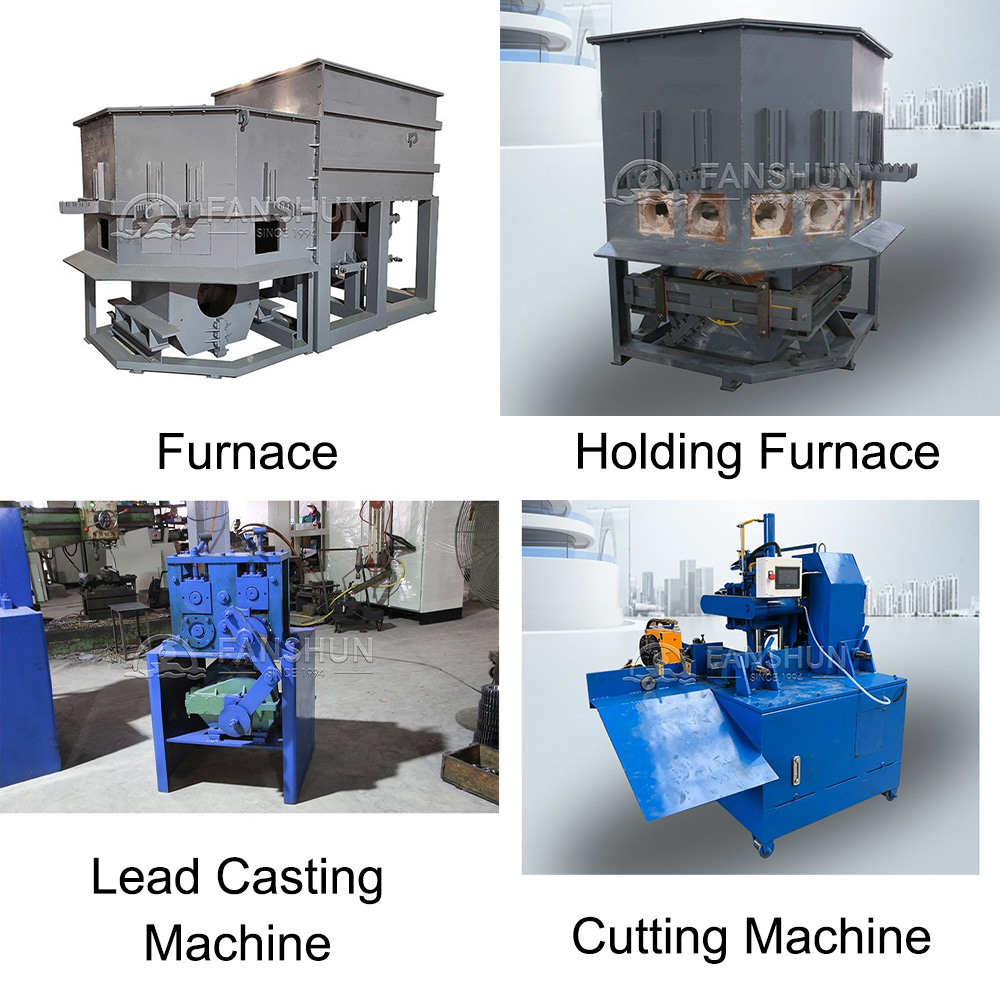

Project Reference Equipment Configuration

| Furnace | Holding Furnace | Tractor | Cutting Machine | Drawing and Peeling Machine | Straightening Machine | Environmental Protection Equipment | Cooling System |

| 75Kw | 75Kw | φ6-60mm 2 units/ φ30-150mm 1 unit | φ6-60mm 1 unit/ φ30-150mm 1 unit | 2 units | 2 units | 1 set | 1 set |

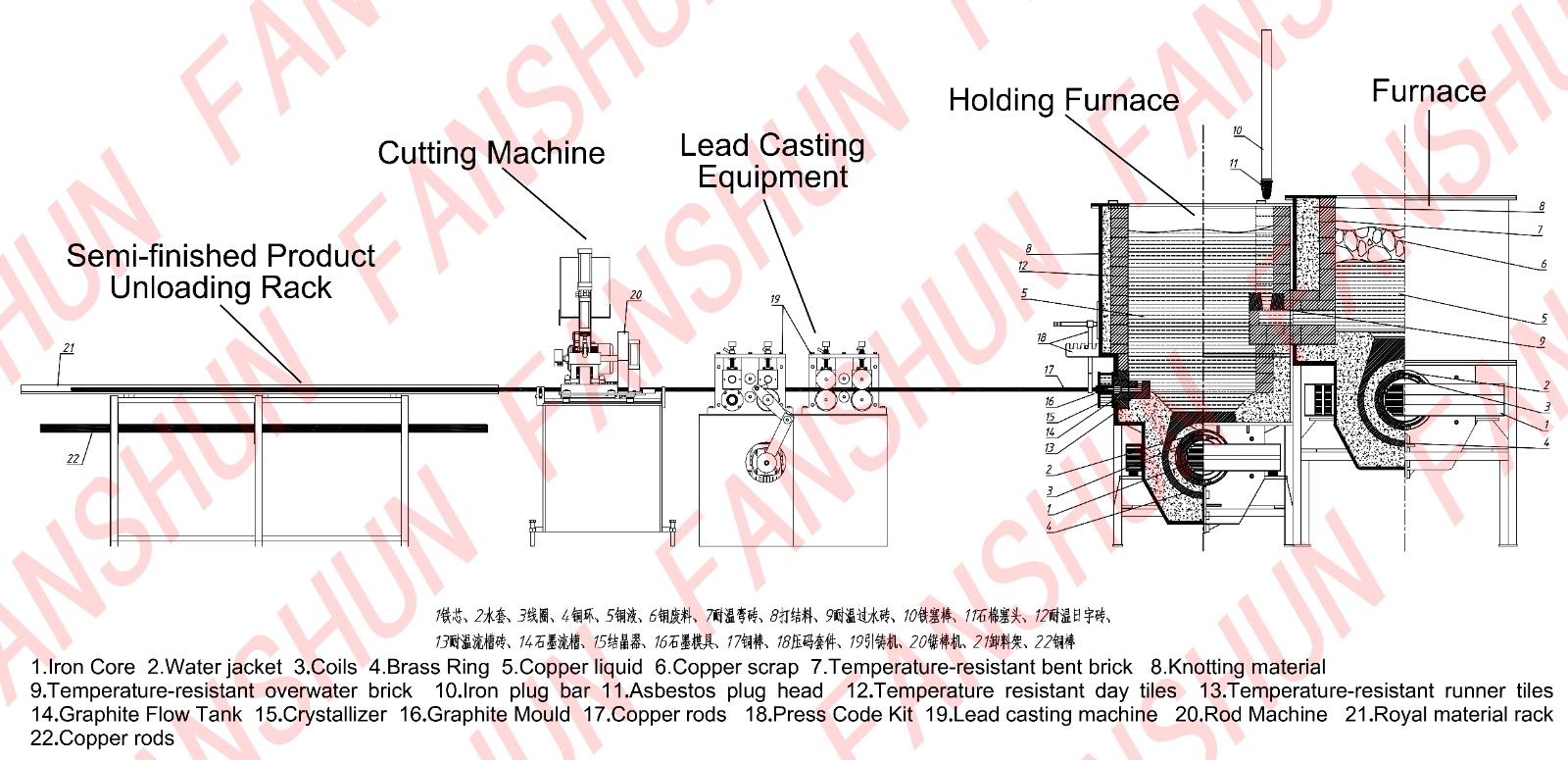

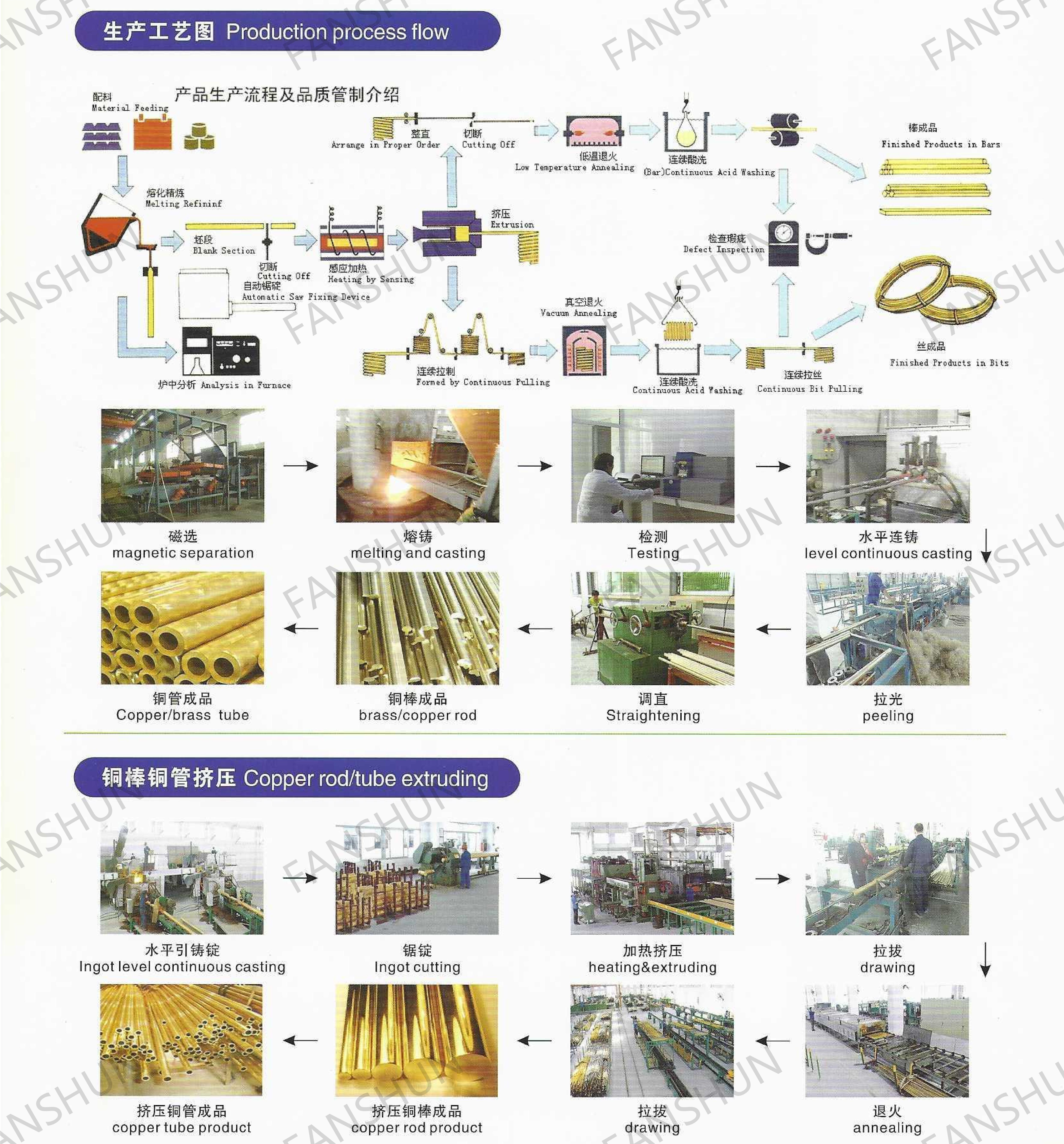

The 150-200T Copper Bar Production Line excels in the high-volume production of copper bars, brass rods, copper wires, copper tubes, and bronze bars. 150-200T Copper Bar Production Line is designed for efficiency and precision, ensuring top-quality output across a range of copper-based products. At the heart of the 150-200T Copper Bar Production Line is the production of copper bars. Raw copper is melted in a furnace, cast into billets, and then extruded into copper bars. This process also includes the creation of brass rods, which are made by alloying copper with zinc, and bronze bars, produced by combining copper with tin or other metals. The 150-200T Copper Bar Production Line is also equipped to manufacture copper wires and copper tubes. Copper wires are drawn from billets and used in electrical and electronic applications, while copper tubes are extruded for plumbing and industrial uses. Both copper wires and copper tubes are integral products of the 150-200T Copper Bar Production Line. Advanced machinery in the 150-200T Copper Bar Production Line ensures that every copper bar, brass rod, copper wire, copper tube, and bronze bar is produced with consistent quality. This includes melting furnaces, casting machines, extrusion presses, and finishing equipment, all of which contribute to the high standards of the finished products. Overall, the 150-200T Copper Bar Production Line efficiently produces a diverse array of products including copper bars, brass rods, copper wires, copper tubes, and bronze bars, meeting the rigorous demands of various industries. |

Equipment Configuration Reference