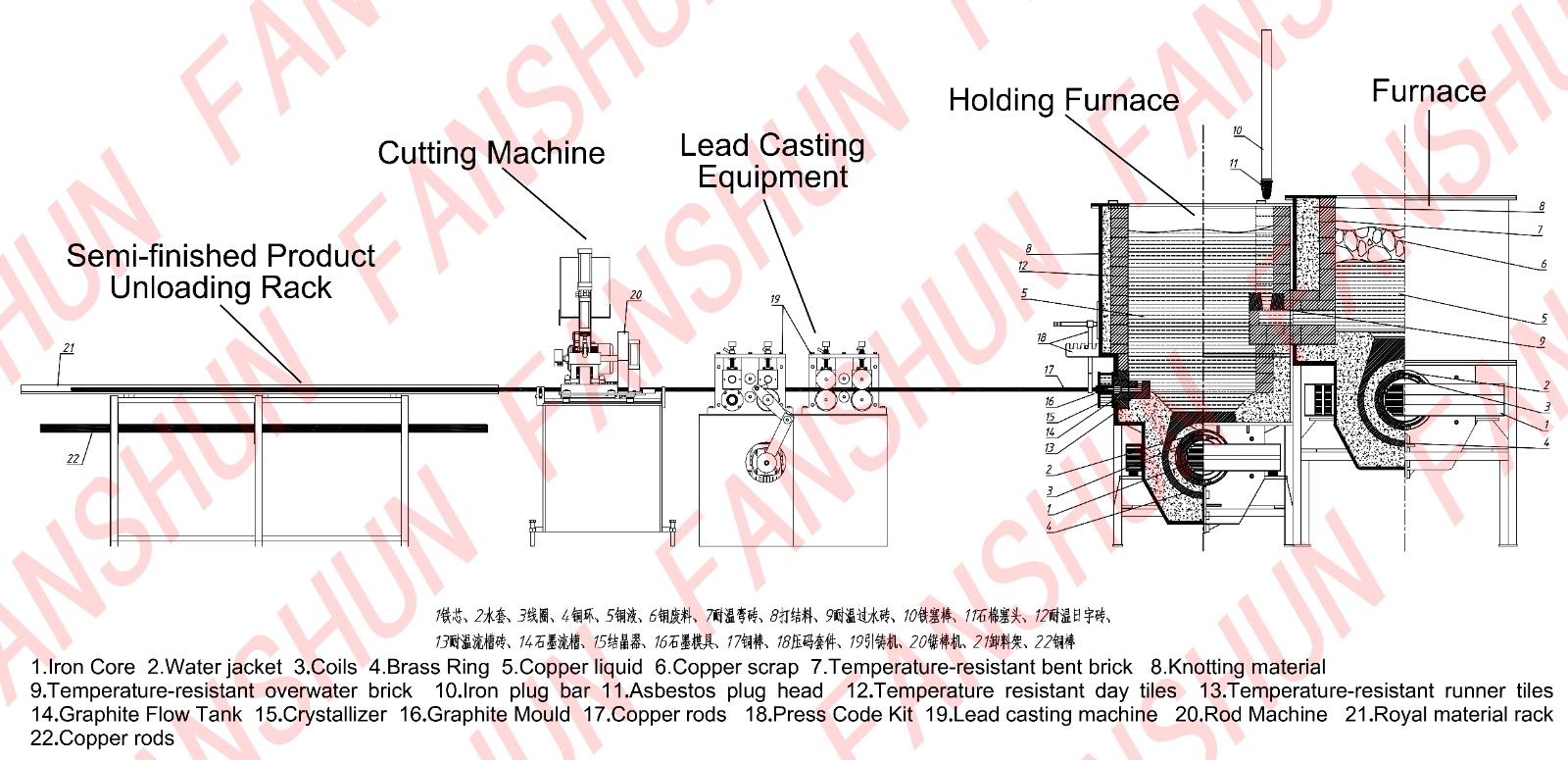

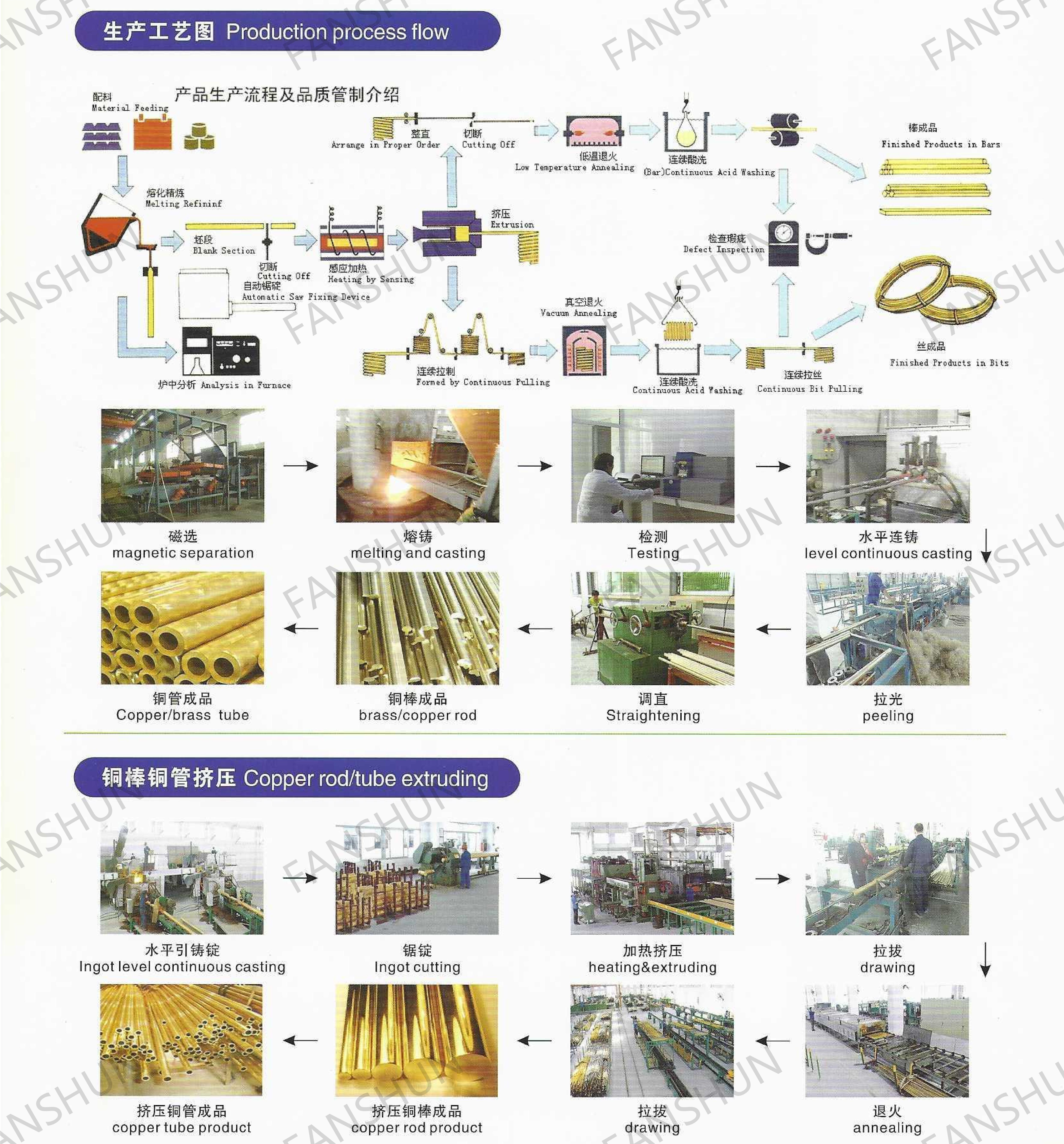

The production of copper bars and brass rods involves a comprehensive process facilitated by specialized equipment and furnaces. At the core of this process are the producing copper rod furnaces, which are essential for melting and shaping the raw materials into usable forms. Copper bars and brass rods are vital components in various industries, including construction, electrical wiring, and manufacturing. These products require precise manufacturing processes to meet stringent quality standards. The first step in the production line is melting the raw materials, such as copper tubes and bronze bars, in the producing copper rod furnaces. These furnaces utilize high temperatures to melt the metals, transforming them into molten form. Once melted, the molten metal is poured into molds to create copper bars and brass rods of desired shapes and sizes. These molds are carefully designed to ensure uniformity and consistency in the final products. After casting, the copper bars and brass rods undergo cooling and solidification processes to achieve their final form. Precision cooling techniques are employed to prevent defects and ensure structural integrity. Quality control measures are implemented throughout the production line to monitor the composition and properties of the copper bars and brass rods. This ensures that the products meet the required standards for strength, conductivity, and durability. The copper tube and bronze bar are integral components in the copper rod production line. Copper tubes are melted alongside bronze bars in specialized furnaces. After melting, the molten metal is poured into molds to form the desired shapes. These molds ensure uniformity and precision in the final products. The cooled copper bars and bronze rods undergo further processing to meet specific industry standards. Quality control measures are implemented throughout the production process to ensure the reliability and performance of the copper bars and bronze rods produced. In summary, the production of copper bars and brass rods involves a sophisticated process that requires specialized equipment and expertise. From melting the raw materials in producing copper rod furnaces to casting, cooling, and finishing the final products, each step is crucial in ensuring the quality and performance of the copper bars and brass rods produced. |

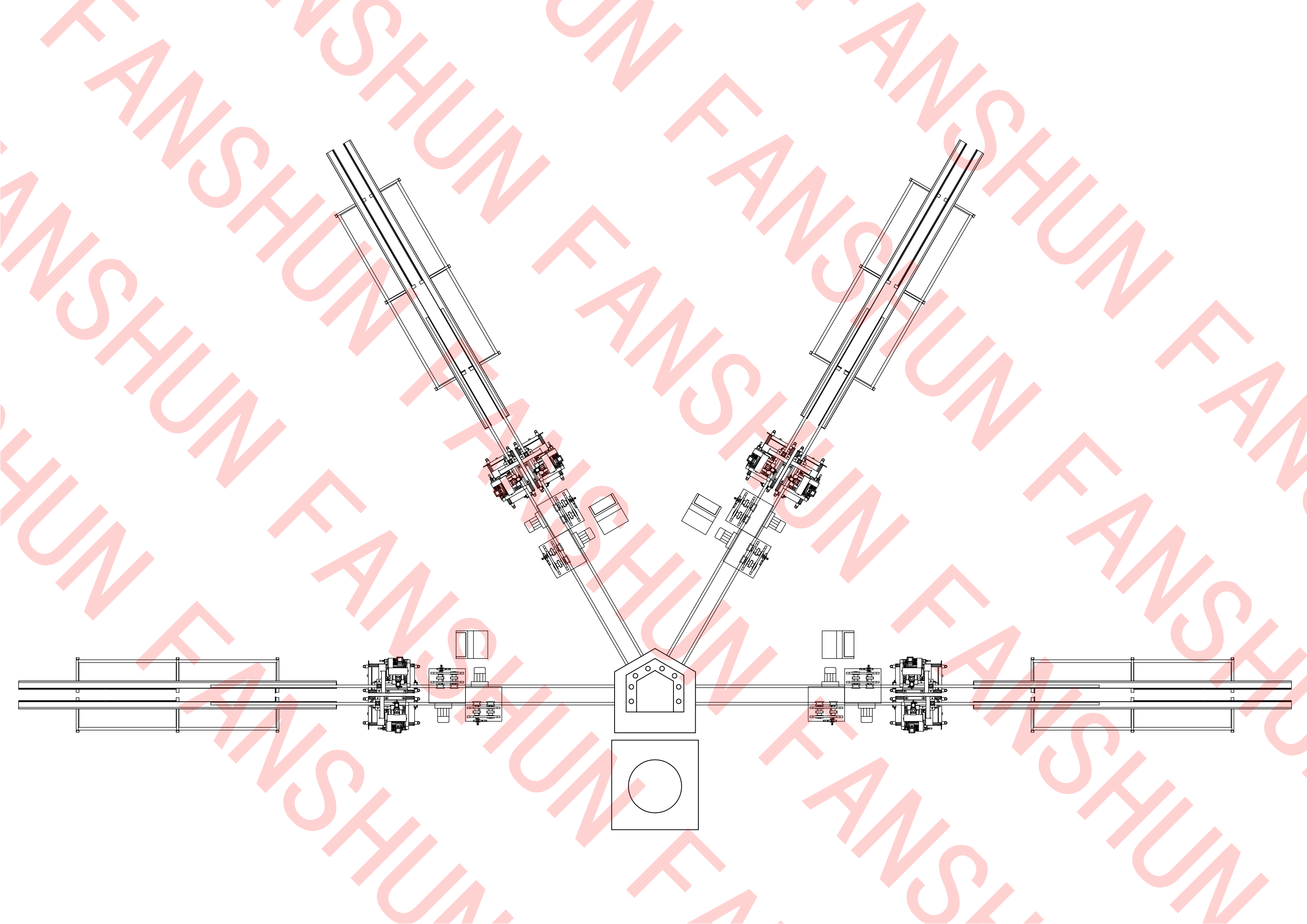

3D Animation Preview

| More information about the 3D animation,please "contact us". |

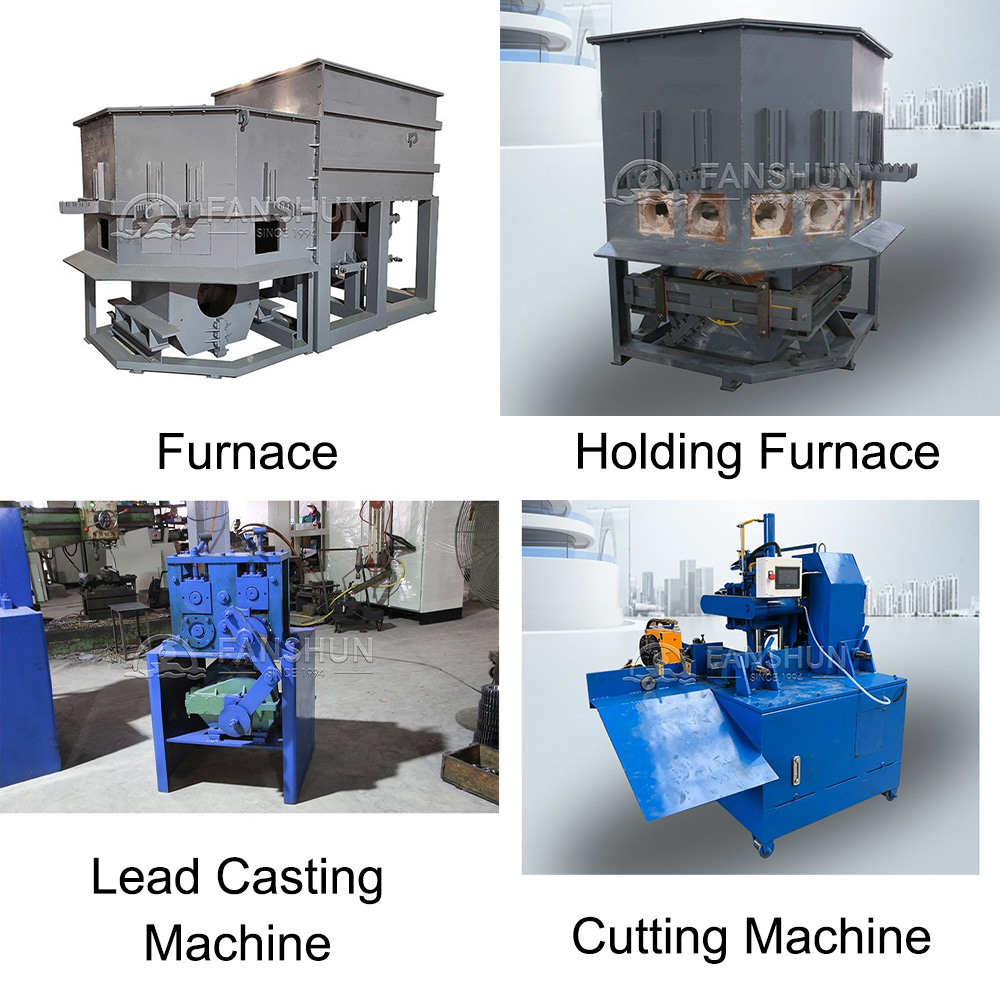

Project Reference Equipment Configuration

| Furnace | Holding Furnace | Tractor | Cutting Machine | Drawing and Peeling Machine | Straightening Machine | Environmental Protection Equipment | Cooling System |

| 180Kw/240Kw | 120Kw | φ6-60mm 7 units/ φ30-150mm 1 unit | φ6-60mm 7 units/ φ30-150mm 1 unit | 3-4 units | 2-3 units | 1 set | 1 set |

Equipment Configuration Reference