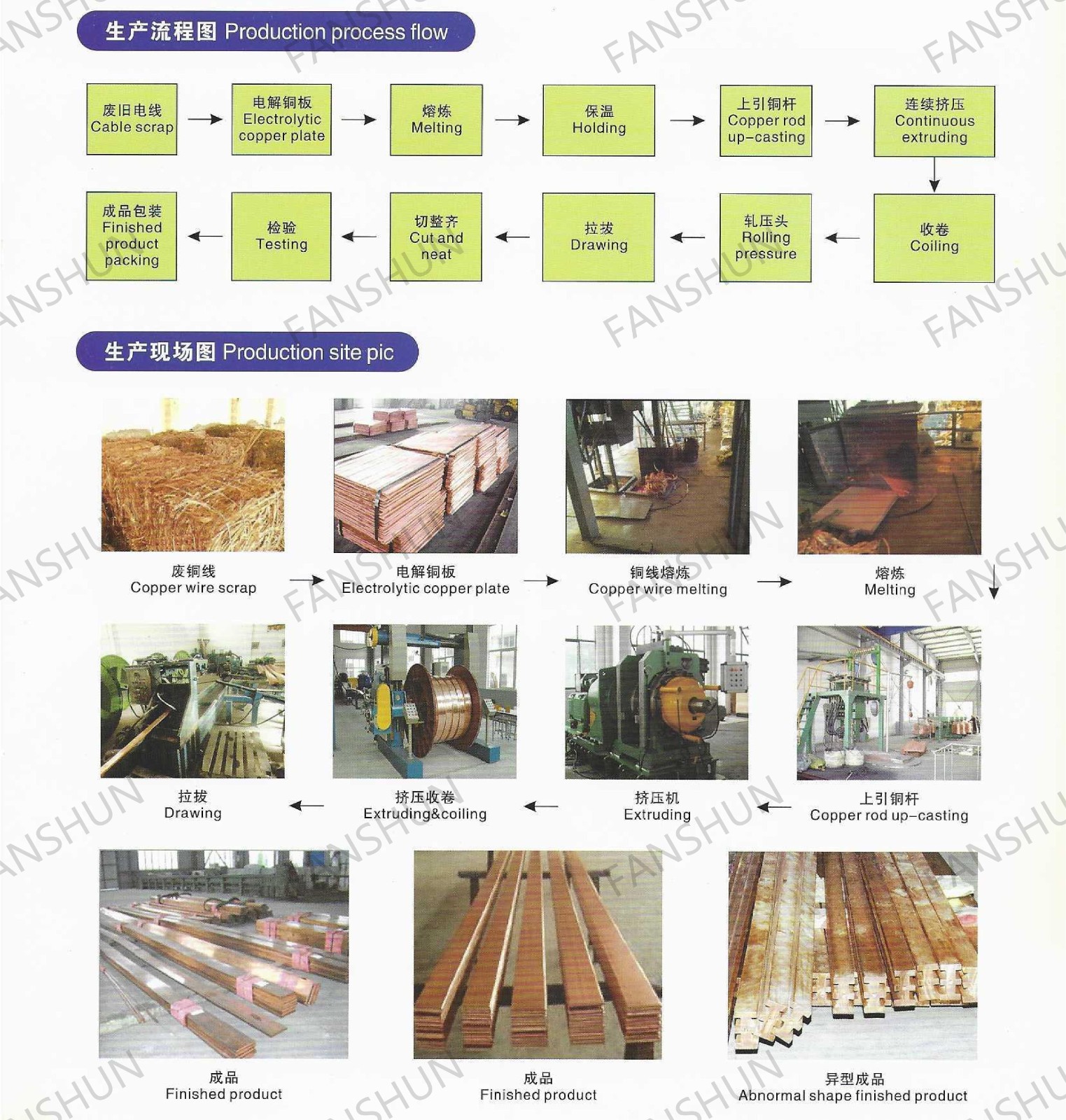

The production of high-quality copper busbars is critical in various industrial applications, especially in the electrical and power generation sectors. One of the most efficient methods for producing these busbars is through the 400T Oxygen-Free Copper Rod Upcasting process. This advanced technique ensures the production of copper rods with superior conductivity, durability, and purity, making them ideal for critical applications. Copper Wire Production and Its ImportanceCopper wire, a key component in electrical systems, relies heavily on the purity and quality of the copper rods used in its production. The 400T Oxygen-Free Copper Rod Upcasting method plays a pivotal role in this process. By producing oxygen-free copper rods, the upcasting process minimizes impurities, enhancing the electrical conductivity of the copper wire. This is particularly important for applications where high-performance and reliable electrical connections are required. Steel Bar Straightening and Cutting Machines in the ProcessWhile copper wire production is a significant focus, the importance of steel bar straightening and cutting machines in the upcasting process cannot be overlooked. steel bar straightening and cutting machines ensure that the copper rods used in the production of copper busbars and wires are perfectly straight and cut to precise lengths. Straightening is crucial as it prevents any deformation during subsequent processing stages, ensuring the final product meets stringent quality standards. Bronze Wire and Its Relation to UpcastingBronze wire, though not produced directly through the upcasting process, shares similarities with copper wire in terms of manufacturing requirements. Bronze wire and copper wire require high-quality, pure raw materials to achieve desired mechanical and electrical properties. The 400T Oxygen-Free Copper Rod Upcasting process, by producing high-purity copper rods, provides an excellent foundation for further alloying processes, such as the creation of bronze. This ensures that the final bronze wire exhibits superior characteristics, making it suitable for specialized applications. 22 Wheel Aluminium Bar Straightening Machine: A Parallel in PrecisionIn the production of aluminium bars, the 22 Wheel Aluminium Bar Straightening Machine plays a role similar to that of the steel bar straightening machine in copper rod production. Precision in straightening is vital to ensure that the final product, whether it is an aluminium bar or a copper busbar, maintains its structural integrity and meets the required specifications. The upcasting process for oxygen-free copper rods benefits from similar precision machinery, ensuring that the rods are perfectly straight and ready for further processing. The Role of Oxygen-Free Copper Rod UpcastingThe 400T Oxygen-Free Copper Rod Upcasting process is a highly efficient method for producing copper busbars. This method involves melting pure copper in a controlled, oxygen-free environment and casting it into rods. The absence of oxygen prevents the formation of oxides, which can weaken the metal and reduce its electrical conductivity. As a result, the copper rods produced are of the highest quality, making them ideal for the production of copper busbars used in high-performance electrical applications. ConclusionThe 400T Oxygen-Free Copper Rod Upcasting process is crucial in the production of high-quality copper busbars, which are essential in various industrial sectors. By ensuring the purity and precision of copper rods, this method plays a pivotal role in the broader manufacturing landscape, including the production of copper and bronze wires. The integration of advanced machinery, such as steel bar straightening and cutting machines, further enhances the quality of the final product, making it an indispensable part of modern manufacturing processes. |

| More information about the 3D animation,please "contact us". |

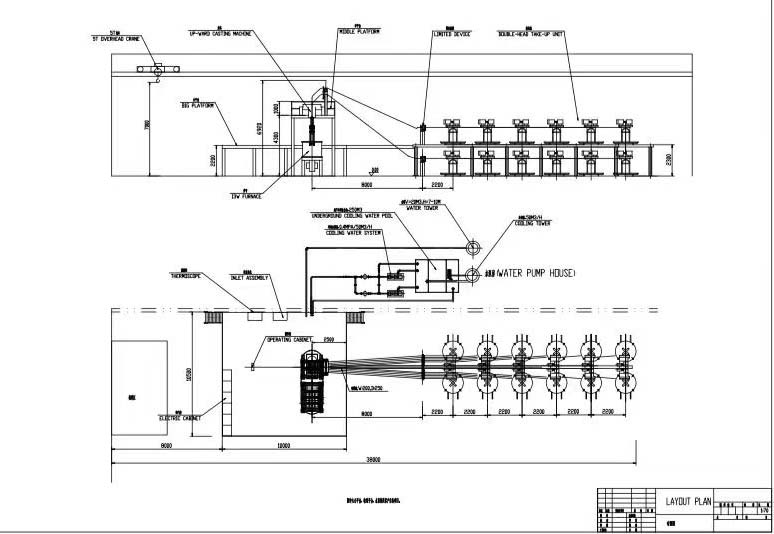

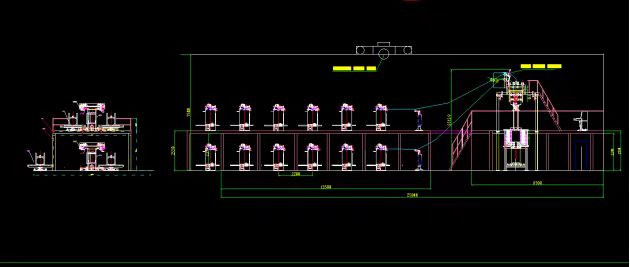

Project Reference Equipment Configuration

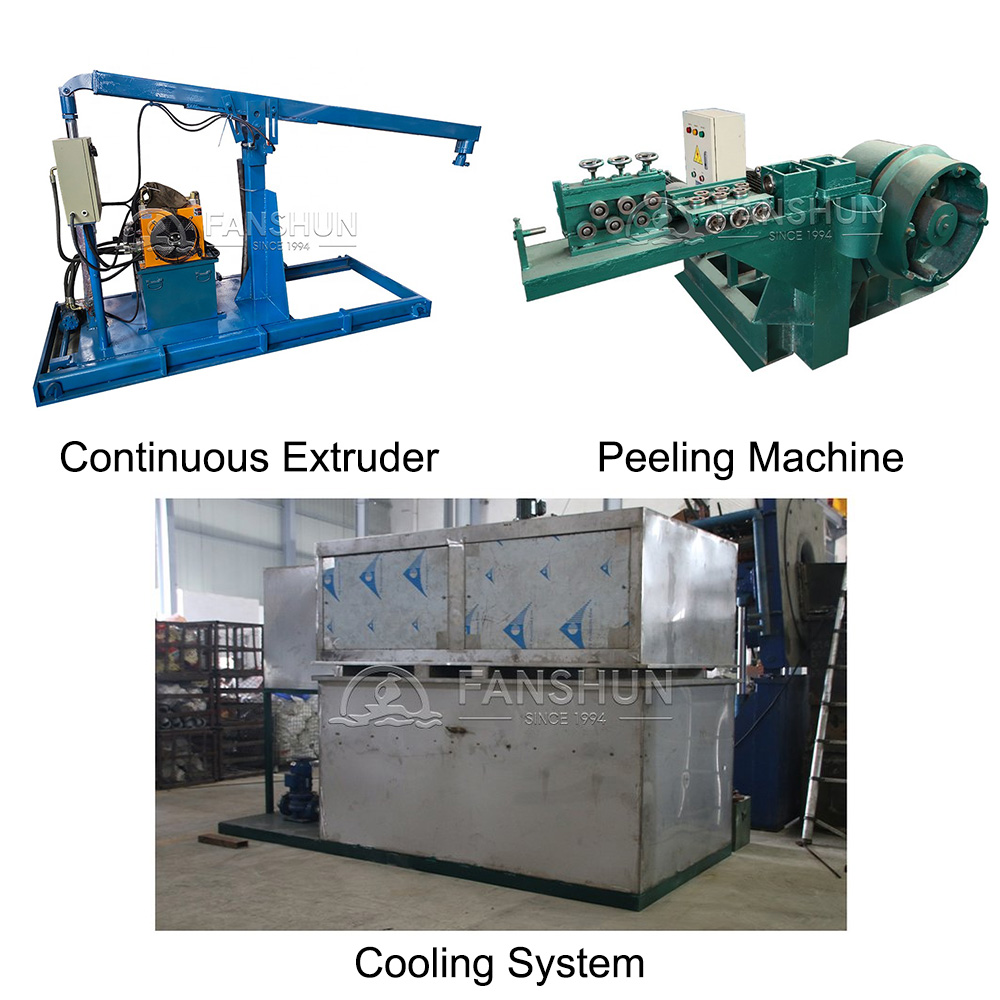

| Furnace | Holding Furnace | Up-Casting Machine | Coiling Machine | Continuous Extruder | Peeling Machine | Cooling System |

75Kw+75Kw Capacity:3T | 75Kw Capacity:2T | 10 heads φ12.5-20mm | 10 units 20 plates | 500# 250Kw | 100T | Volumn:80T Water Storage:30T |

Equipment Configuration Reference