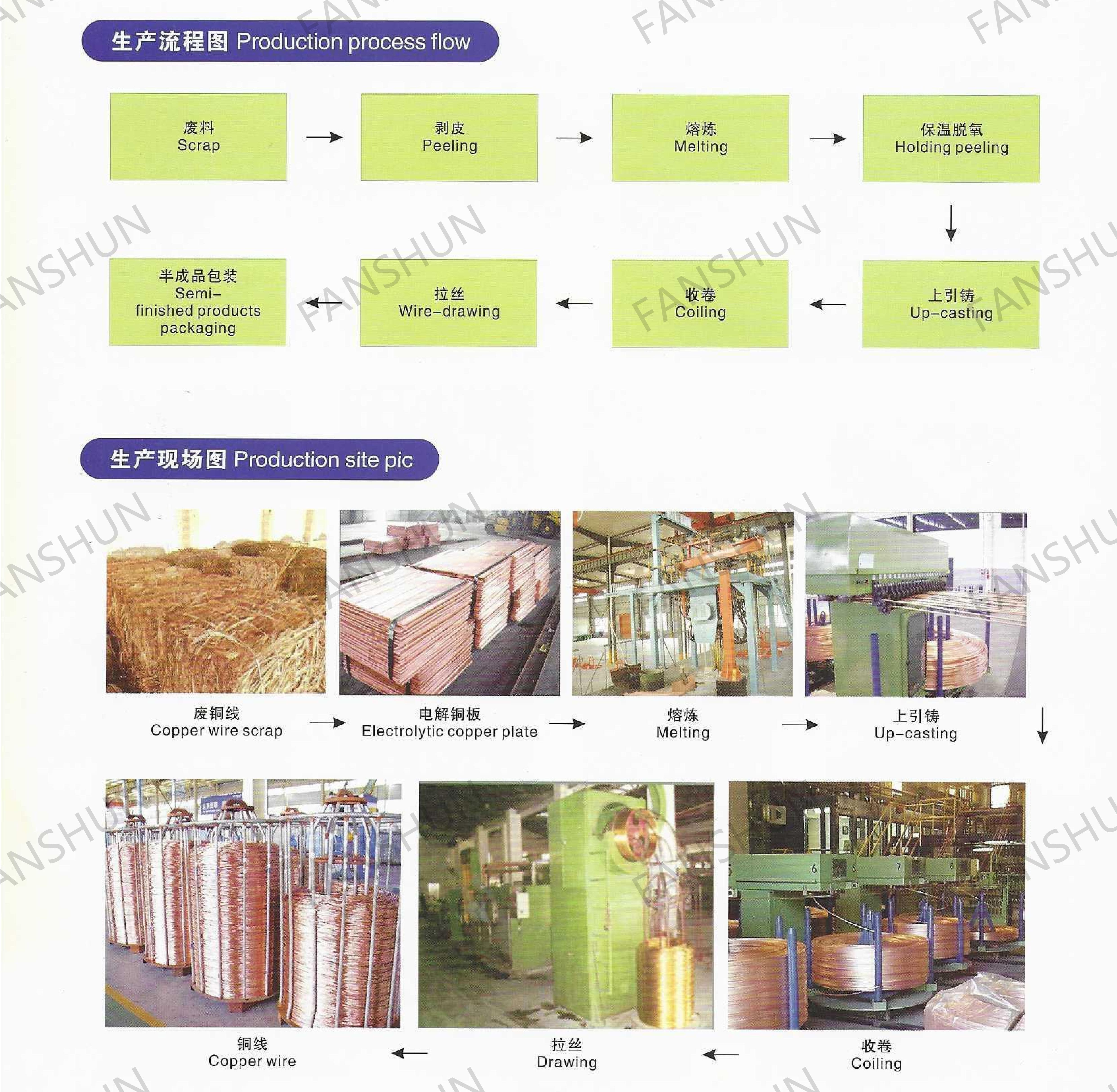

| Copper bar machine、plate straightening machine、melting scrap metal smelting machineryplay indispensable roles in shaping and transforming raw materials into usable products. Among these, the copper bar machine stands tall.The copper bar machine is utilized for shaping copper bars into various forms and dimensions.Accompanying the copper bar machine is the plate straightening machine.Plate straightening machine plays a critical role in preparing copper plates for further processing, guaranteeing the quality and precision of the final products.In addition to the rods cast by the copper bar machine and the plates finished by the plate straightening machine, copper wire production also represents another important aspect of the metal manufacturing industry. Bronze wire, renowned for its unique properties and versatility,bronze wire typically consists of a combination of copper and tin. Bronze wire is a versatile material renownedcommonly , bronze wire is commonly used in sculpting due to its malleability, while specialized bronze wire is also employed in electrical applications for its conductivity.While crafting a sculpture, the artist skillfully weaved bronze wire through the intricate design, ensuring each detail was meticulously formed with the sturdy and versatile material, bronze wire, known for its durability and aesthetic appeal. Furthermore, in the realm of construction, the rebar straightening machine emerges as a pivotal player. Rebar straightening machine is indispensable for straightening and shaping reinforcing steel bars (rebars), crucial elements in concrete structures. The rebar straightening machine typically features a robust frame with adjustable rollers or guides. The rebar straightening machine is a vital tool in construction, efficiently straightening steel rebars to ensure structural integrity and safety in building projects. Central to the entire metal fabrication process is the melting scrap metal smelting machinery. Using the specialized melting scrap metal smelting machinery to melt and refine the scrap metal into high-quality alloys, demonstrating the remarkable efficiency and effectiveness of the melting scrap metal smelting machinery in the production process. From shaping copper bars and plates to producing bronze wire and straightening rebars, each machine plays a crucial role in ensuring the quality and functionality of the final products. |

3D Animation Preview

| More information about the 3D animation,please "contact us". |

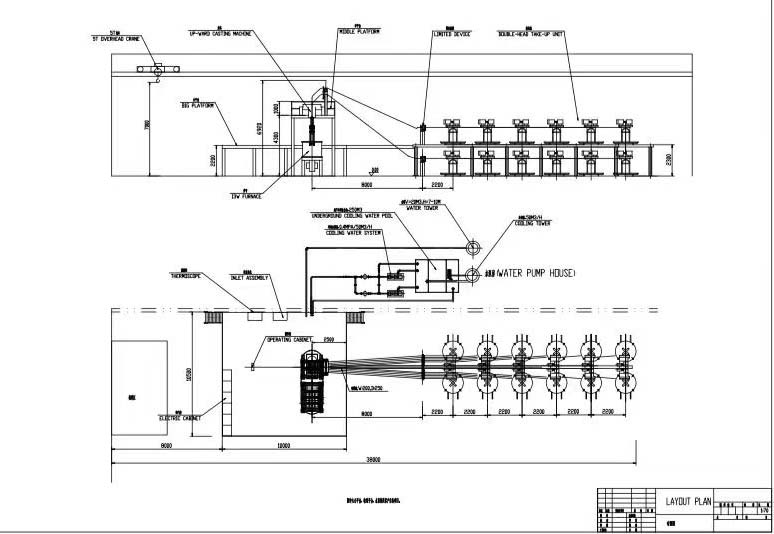

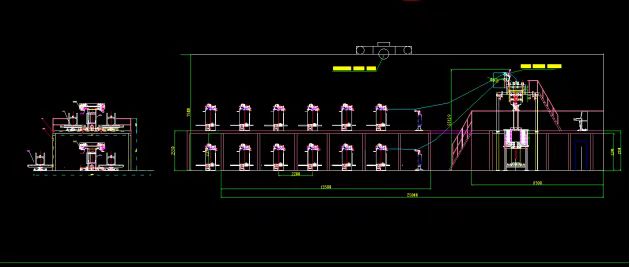

Project Reference Equipment Configuration

| Furnace | Holding Furnace | Up-Casting Machine | Coiling Machine | Environmental Equipment | Cooling System |

| 75Kw+75Kw | 75Kw | 10 heads φ8-120mm | 5 units 10 plates | 600# Bag 55Kw Ventilator | Volumn:100T Water Storage:20T |

Equipment Configuration Reference