3D Animation Preview

| More information about the 3D animation,please "contact us". |

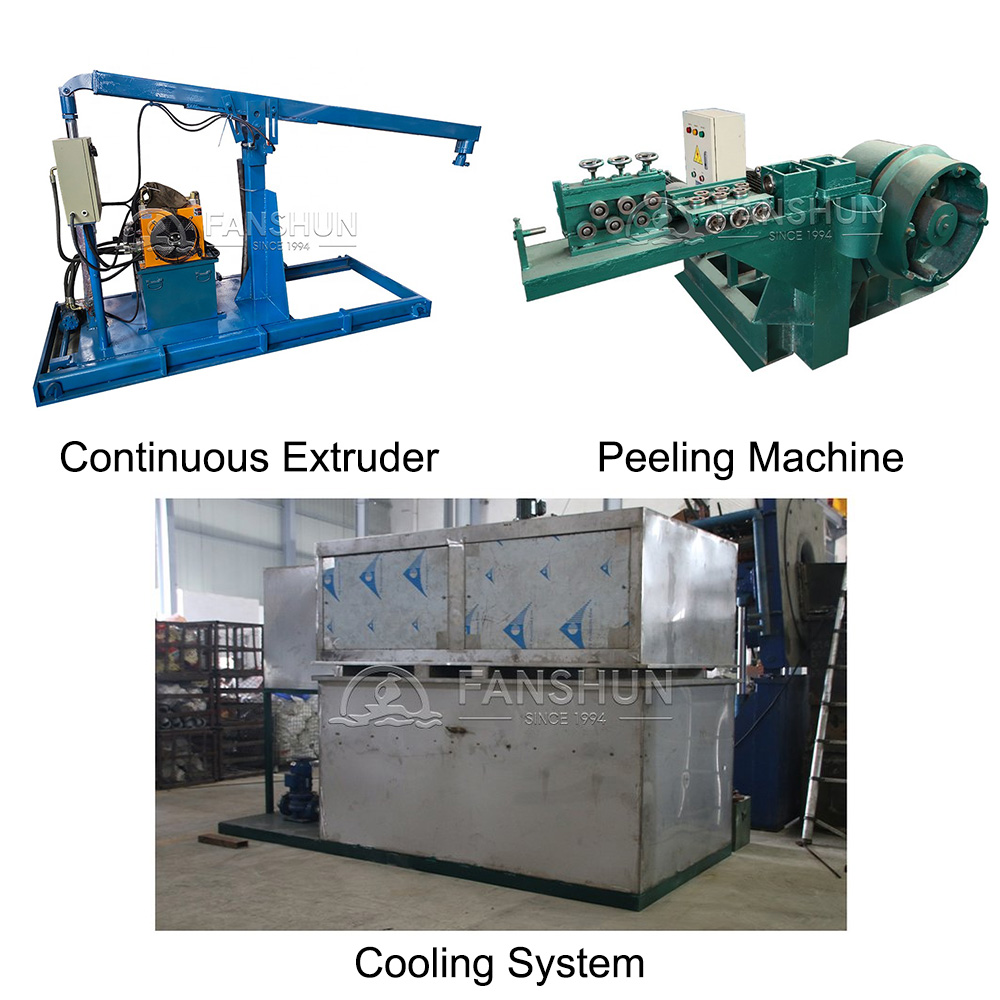

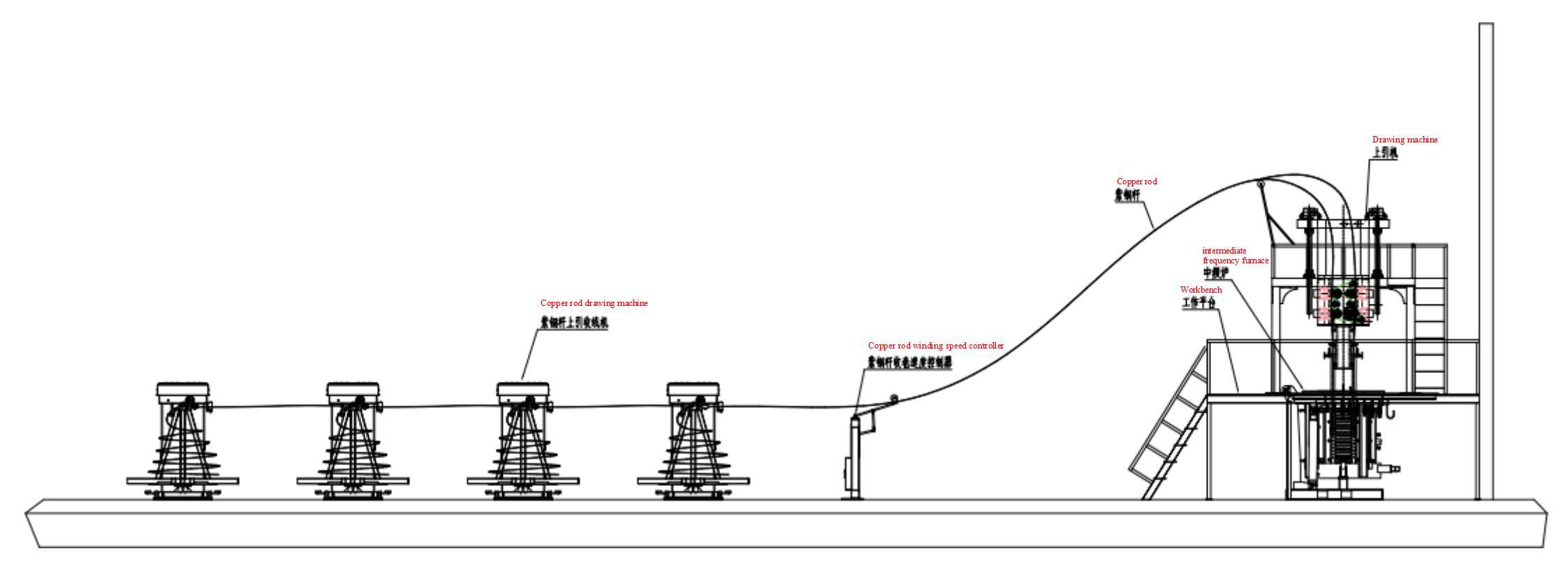

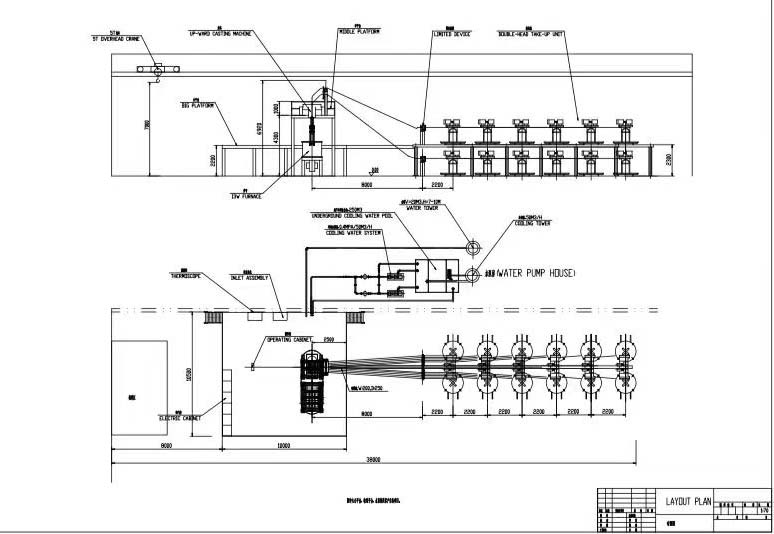

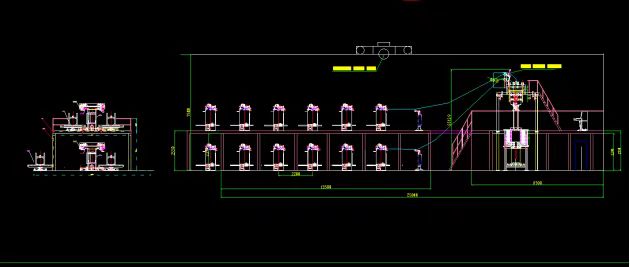

Project Reference Equipment Configuration

| Medium Frequency Furnace | Industrial Frequency Holding Furnace | Up-Casting Machine | Coiling Machine | Continuous Extruder | Peeling Machine | Cooling System |

350Kw 1T | / | 4 heads | 2 units 4 plates | 350# 90Kw | 50T | Volumn:30T Water Storage:10T |

The medium frequency furnace for Oxygen Free Copper Rod Upcasting plays a crucial role in the production of high-quality oxygen-free copper rods, which are vital for various industrial applications. This process is essential for producing copper rods with exceptional purity and performance, suitable for use in applications such as copper wire manufacturing and bronze wire production. The Oxygen Free Copper Rod Upcasting process involves melting high-purity copper in a medium frequency furnace. The furnace uses electromagnetic induction to generate the heat required to melt the copper efficiently. Once melted, the copper is continuously cast into rod form, maintaining its oxygen-free status. This method ensures that(Iron ingot ,Bronze wire、copper wire) the final product—Oxygen Free Copper Rods—is free from contaminants and oxidation, which is crucial for applications demanding high electrical conductivity and corrosion resistance. In the context of industrial production, Steel bar straightening machines often come into play when processing related materials. These machines are used to straighten bent or deformed steel bars, ensuring they meet the required specifications. However, the focus here is on copper processing, Iron ingot ,Bronze wire,Steel bar straightening machine,copper wire where the quality of the Oxygen Free Copper Rods directly impacts the production of copper wire and bronze wire. The medium frequency furnace provides several advantages in the Oxygen Free Copper Rod Upcasting process. It offers precise temperature control, which is essential for maintaining the high purity of the copper. The continuous casting process also minimizes waste and enhances production efficiency. The resulting oxygen-free copper rods are ideal for use in electrical wiring, high-performance connectors, and other applications requiring superior conductivity. The Iron ingots produced from various casting processes can also benefit from the precision and efficiency offered by modern furnaces, although (Iron ingot ,Bronze wire,Steel bar straightening machine,copper wire)they are not directly related to the copper rod upcasting process. Nevertheless, Iron ingot ,Bronze wire,Steel bar straightening machine,copper wire understanding the role of different furnaces and processes helps in comprehending the overall landscape of industrial metal processing. In summary, the medium frequency furnace for Oxygen Free Copper Rod Upcasting is integral to producing high-quality copper rods used in copper wire and bronze wire applications. The furnace's ability to produce oxygen-free copper ensures the highest performance standards, making it a vital tool in the manufacturing of various electrical and industrial components. |

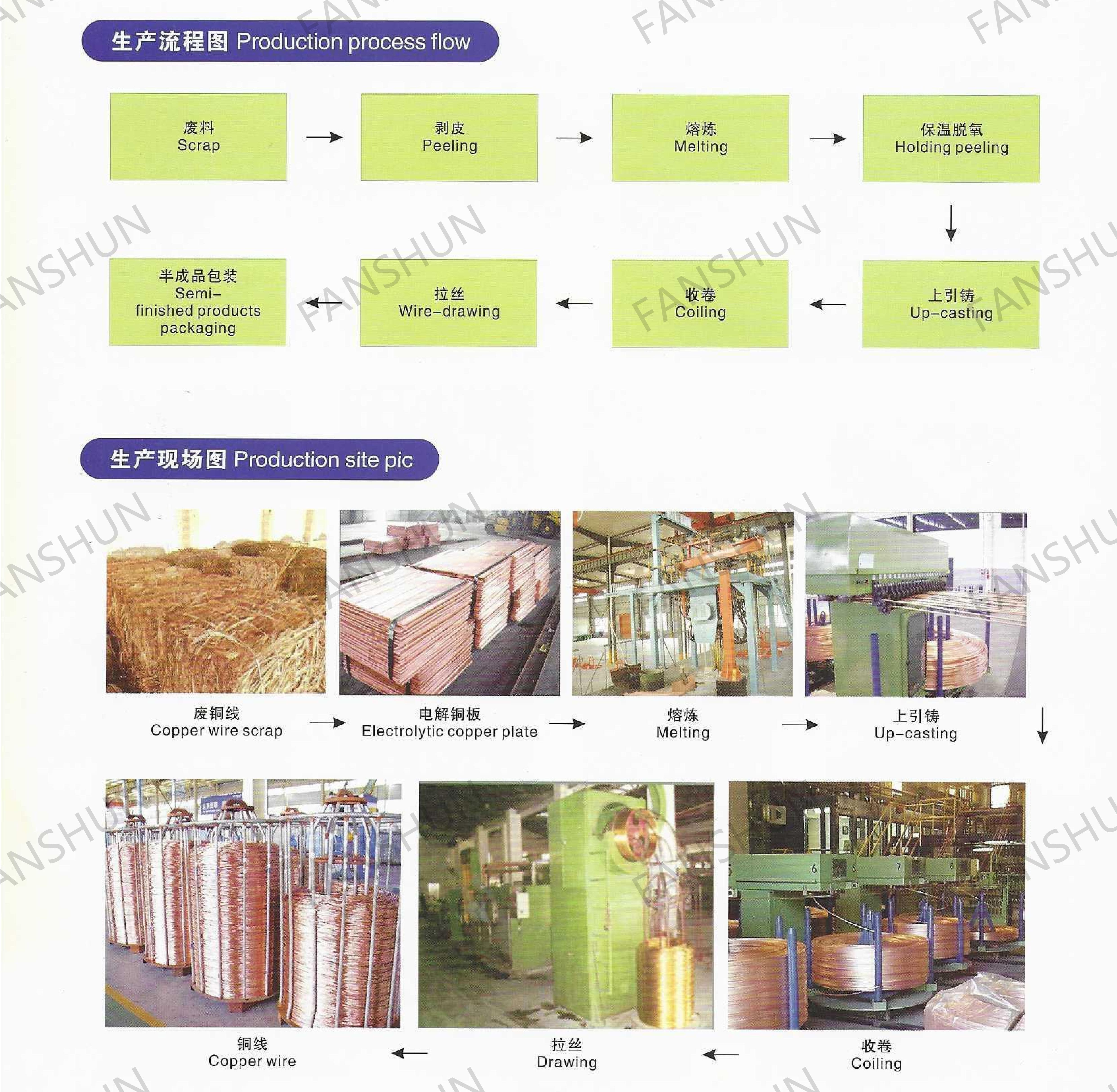

Equipment Configuration Reference