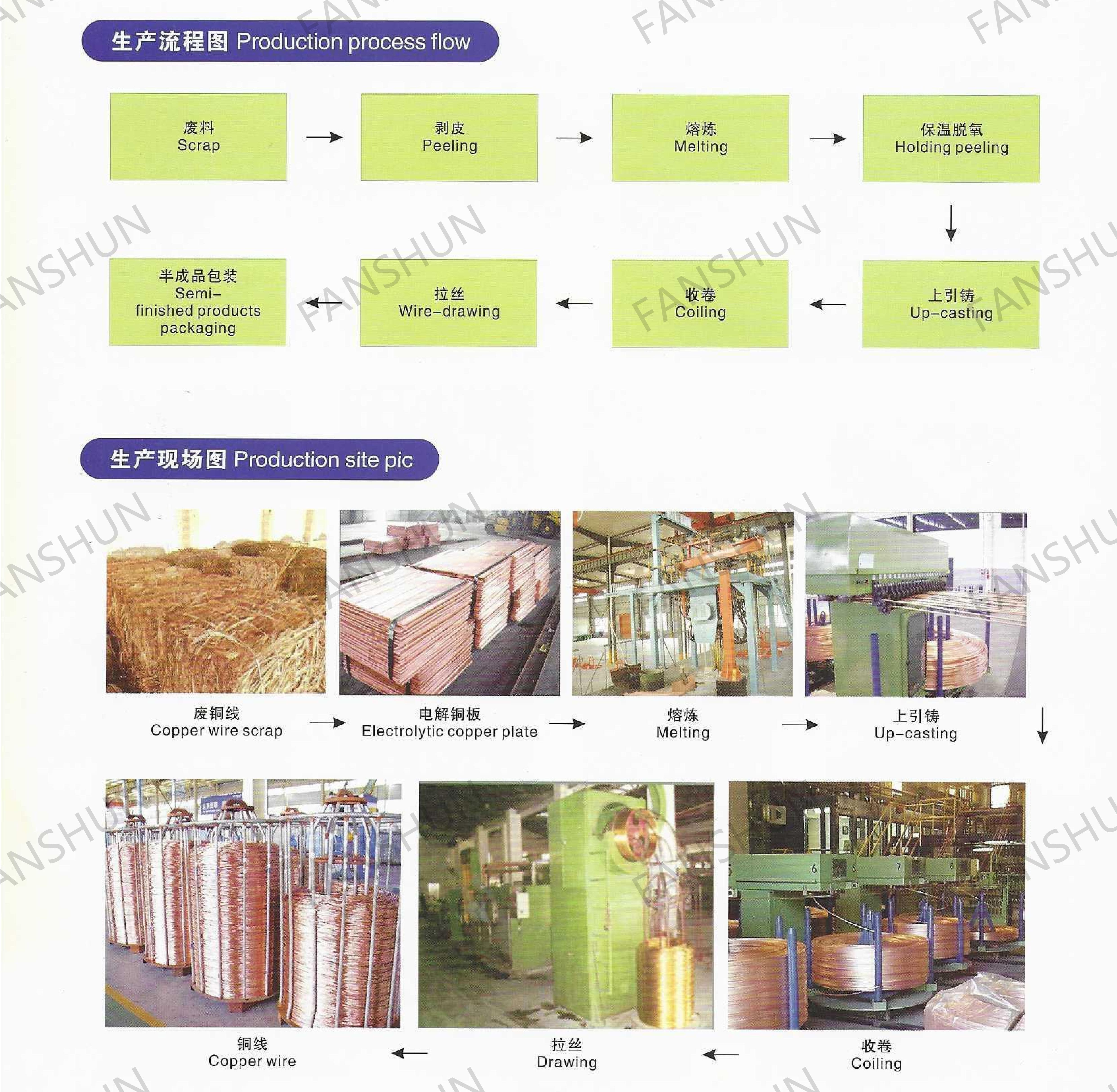

800T Copper Rod Production from Scrap Copper and Copper Cathodes The production of 800T copper rods from scrap copper and copper cathodes involves a sophisticated casting process to ensure high-quality copper rods and copper rows. For example, this method copper row up casting utilizes advanced equipment for efficiency and purity. Production Process and Working Principle: For example, this production process of copper row up casting starts with melting scrap copper in a scrap copper electric furnace. Scrap copper electric furnace refines the copper, removing impurities to prepare it for casting. Once the copper is molten, it is transferred to the Copper Wire Up Casting Machine. Copper Wire Up Casting Machine is crucial in the Copper Wire Making Equipment setup, using Copper Rod Upward Casting Equipment to form the copper into rods. In the Copper Wire Up Casting Machine and Copper row up casting machine, the molten copper is poured into molds and solidifies as it moves upward. For example, this method copper row up casting, known as Copper Rod Upward Casting, ensures that the copper rods are free from defects and have a consistent quality. The Copper Wire Up Casting Machine plays a key role in achieving high-quality results through precise temperature control and casting parameters. Advantages: High Purity: The Copper Wire Up Casting Machine ensures that the copper rods are of high purity, essential for producing quality copper wire and other products. Consistency: The Copper Rod Upward Casting Equipment guarantees uniformity and high standards in the copper rods, thanks to the controlled casting process. Efficiency: Utilizing scrap copper and advanced Copper Wire Making Equipment enhances the production efficiency and cost-effectiveness. Applications: The 800T copper rods produced are used in various applications requiring high-purity copper, such as in the electrical and electronics industries. These rods are critical for producing reliable copper wire and other copper components. In summary, the production of 800T copper rods from scrap copper and copper cathodes employs the Copper Wire Up Casting Machine and Copper Rod Upward Casting Equipment. This process, involving the scrap copper electric furnace and Copper Wire Making Equipment, ensures the production of high-quality copper rods suitable for demanding applications. The key words used in this article are: Copper Wire Up Casting Machine,Copper Wire Making Equipment Copper rod upward casting equipment,Copper row up casting, scrap copper electric furnace. |

3D Animation Preview

| More information about the 3D animation,please "contact us". |

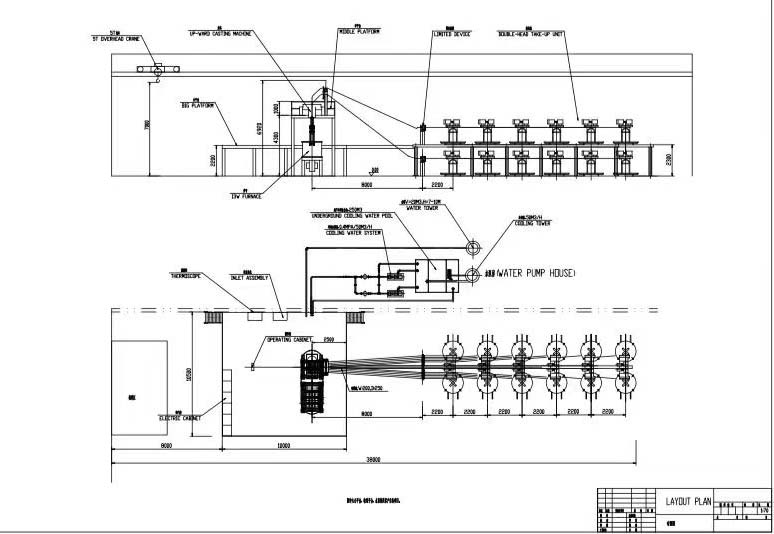

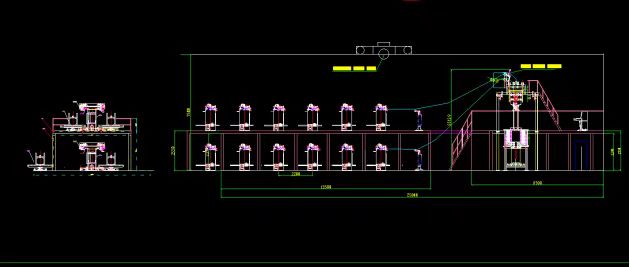

Project Reference Equipment Configuration

| Furnace | Holding Furnace | Up-Casting Machine | Coiling Machine | Environmental Equipment | Cooling System |

| 120Kw+120Kw | 120Kw | 16 heads φ8-20mm | 8 units 16 plates | 800# Bag 75Kw Ventilator | Volumn:200T Water Storage:30T |

Equipment Configuration Reference