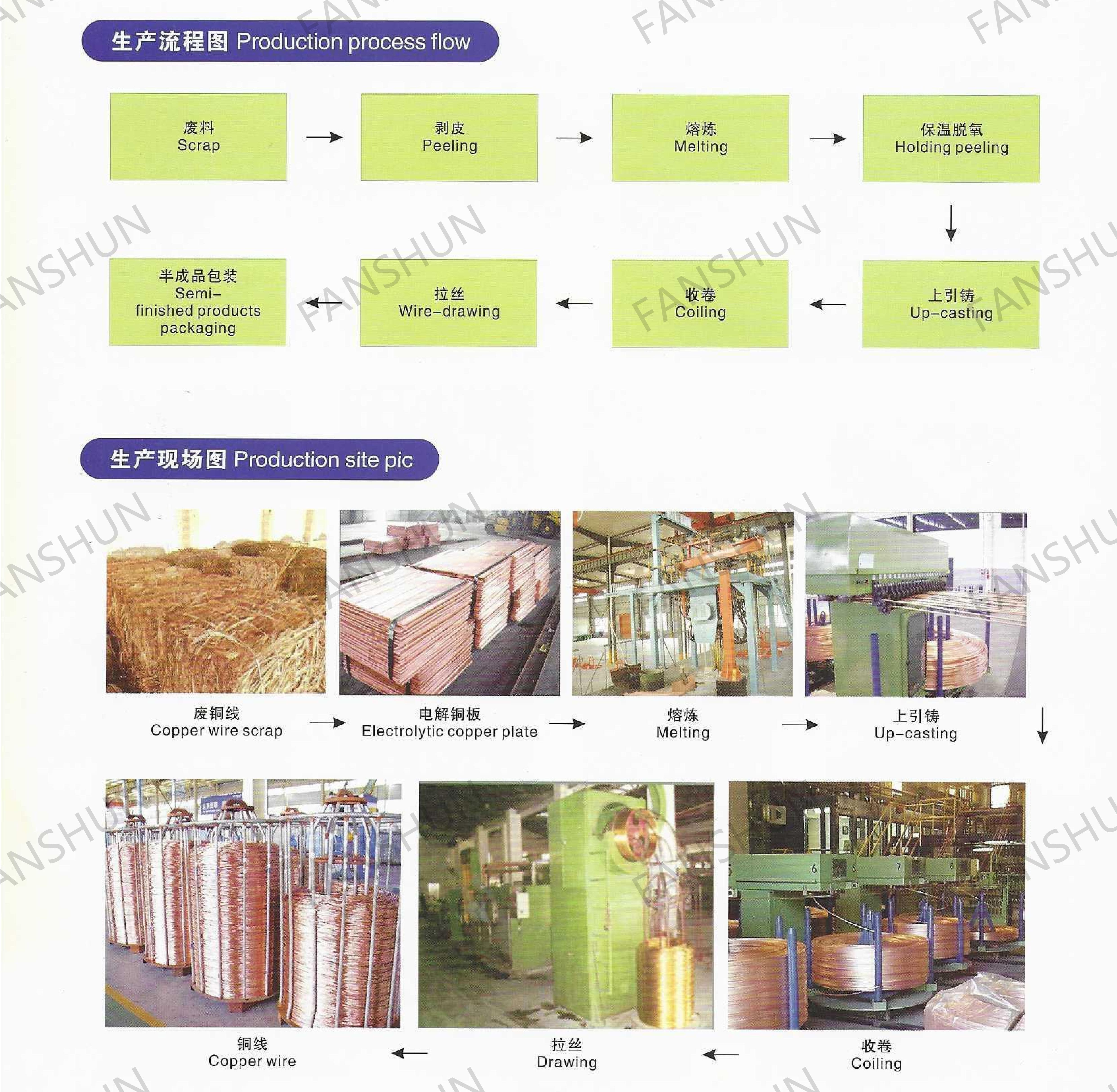

The 100T Oxygen-Free Copper Rod Upcasting process involves melting copper cathode plates in a medium frequency furnace. This method is crucial for producing high-purity copper rods and directly impacts the quality of copper wire, brass wire, and bronze wire. The upcasting technique ensures continuous casting of long, oxygen-free copper rods. The use of copper cathode plates guarantees that the final copper wire, brass wire, and bronze wire are of exceptional quality.

Advantages

High Purity: Upcasting from copper cathode plates ensures that copper wire, brass wire, and bronze wire are made from pure, oxygen-free copper.

Efficiency: The medium frequency furnace boosts the efficiency of the process, producing high-quality copper wire, brass wire, and bronze wire.

Versatility: The process not only creates oxygen-free copper rods but also yields premium copper wire, brass wire, and bronze wire. Starting with copper cathode plates ensures the highest standards for all products.

Quality: Using copper cathode plates reduces impurities, resulting in top-tier copper wire, brass wire, and bronze wire.

Applications

The upcasting process, using copper cathode plates in a medium frequency furnace, is essential in:

Electrical Industry: Producing high-purity copper wire.

Manufacturing: Supplying high-quality brass wire and bronze wire.

Refining: Utilizing copper cathode plates to ensure superior copper wire, brass wire, and bronze wire.

Summary

The 100T Oxygen-Free Copper Rod Upcasting process, using copper cathode plates, guarantees the production of premium copper wire, brass wire, and bronze wire. This method ensures high purity and quality throughout the process.

Project Reference Equipment Configuration

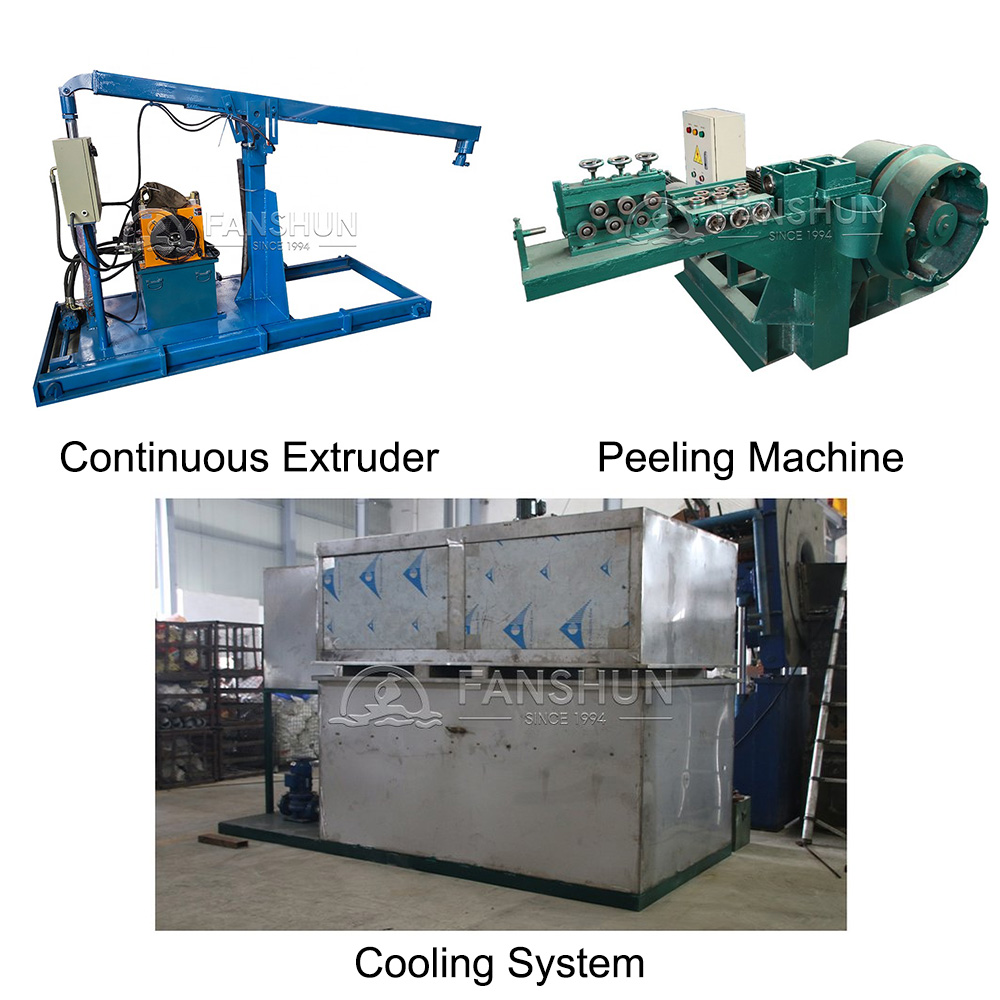

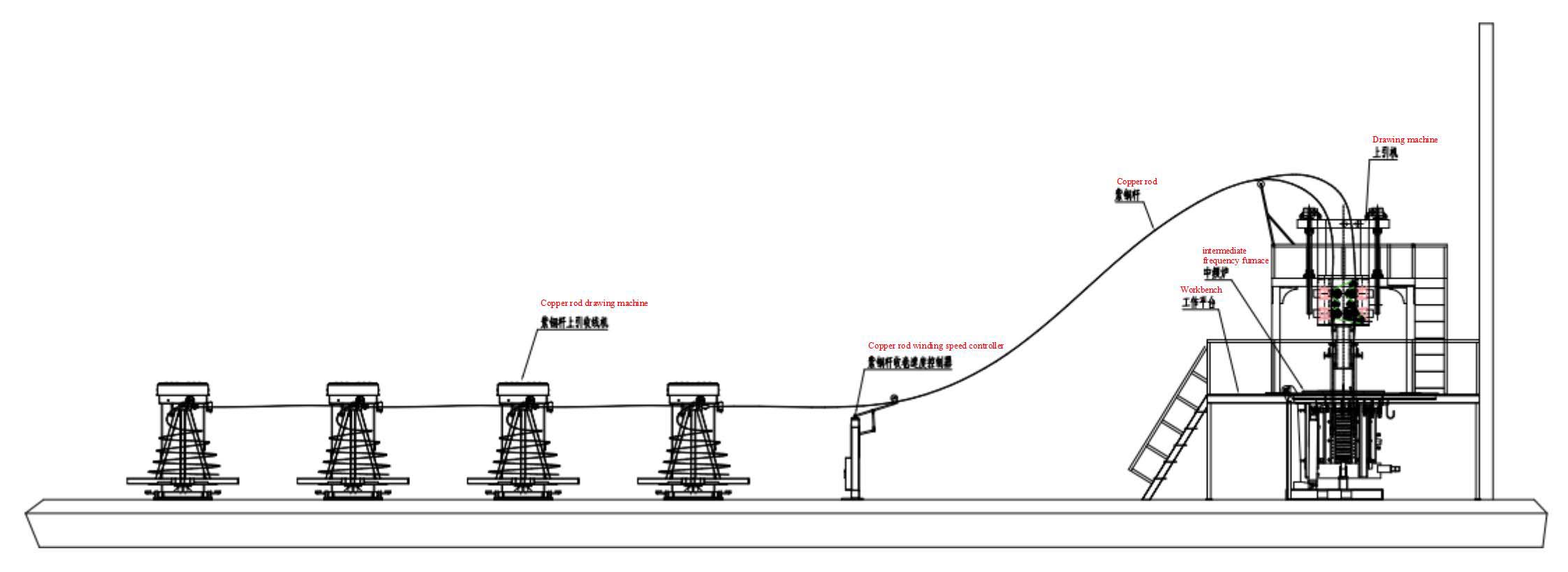

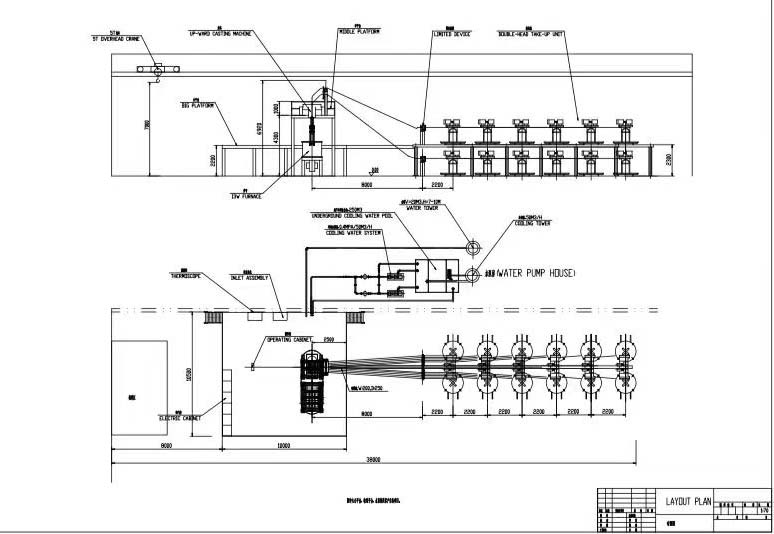

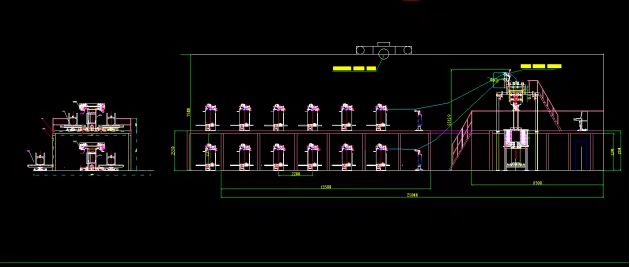

| Medium Frequency Furnace | Industrial Frequency Holding Furnace | Up-Casting Machine | Coiling Machine | Continuous Extruder | Peeling Machine | Cooling System |

250Kw 0.5T | 75Kw | 6 heads | 6 units 12 plates | 400# 160Kw | 50~100T | Volumn:50T Water Storage:20T |

Equipment Configuration Reference