| The cans aluminum smelting furnace is an essential piece of equipment designed specifically for melting aluminum cans and other aluminum scrap. This type of furnace is crucial in the recycling process, efficiently converting used aluminum cans into molten metal that can be reused for various applications. The Melting aluminum electric furnace is a key variant of this technology, utilizing electric power to melt aluminum with high precision and energy efficiency. This electric furnace provides a controlled environment that ensures the quality of the molten aluminum is maintained, making it ideal for applications requiring consistent and high-quality metal. Furnace melting aluminum in general refers to the process of heating aluminum to its melting point using various types of furnaces, including the cans melting furnace. These furnaces are designed to handle different types of aluminum scrap and are essential for efficient recycling and metal recovery. The cans aluminum smelting furnace and cans melting furnace are particularly effective in processing aluminum cans, which are often collected and recycled to produce new aluminum products. In addition to aluminum melting, facilities often use a Casting Copper ingot Production Line to handle copper ingots, complementing their operations with the ability to cast copper alongside aluminum. This production line is crucial for producing high-quality copper ingots, which are essential for various industrial applications. By integrating a Casting Copper ingot Production Line with aluminum melting technologies, manufacturers can streamline their metal processing operations, ensuring both aluminum and copper are handled efficiently. Overall, the cans aluminum smelting furnace and Melting aluminum electric furnace offer advanced solutions for aluminum recycling and melting, with the Furnace melting aluminum process ensuring high-quality molten metal. The cans melting furnace specifically targets the recycling of aluminum cans, while the Casting Copper ingot Production Line provides additional capabilities for copper processing. Together, these technologies enhance the efficiency and versatility of metal production and recycling operations. |

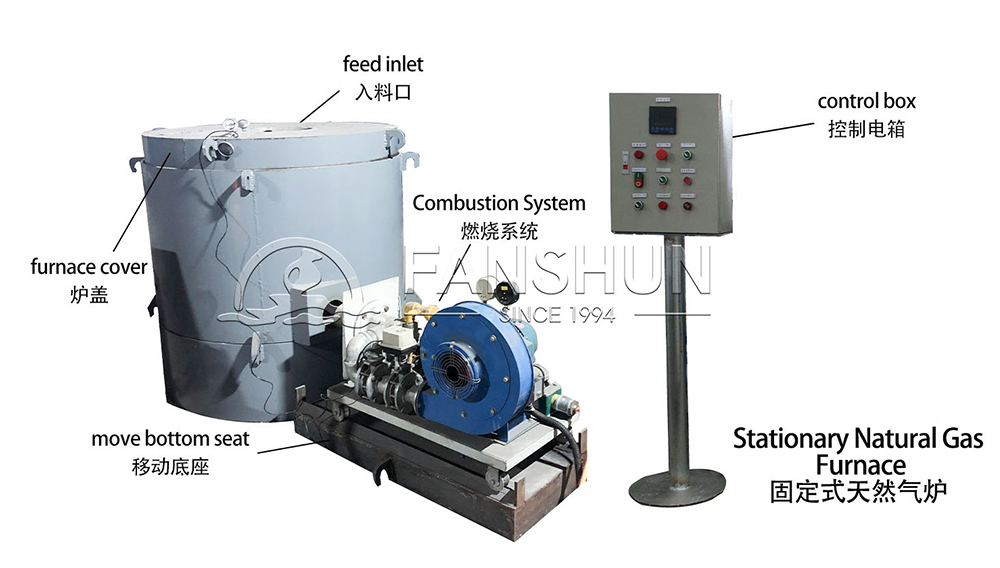

Products Description

Product Size

| Model | Capacity(kg) | Melting speed(kg/h) | energy consumption |

| 300 | 200 | 300 | natural gas 120-150m³/t diesel dye 120-150kg/t |

| 500 | 500 | 300 | |

| 1000 | 1000 | 300 | |

| 1500 | 1500 | 300 |

Detailed images