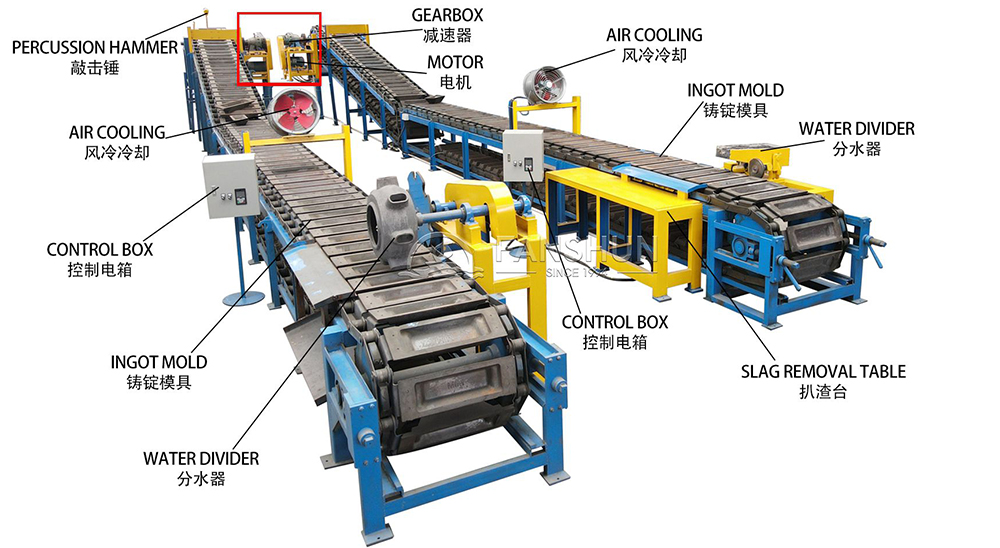

The Copper Casting Machine is a cutting-edge solution for the efficient production of high-quality copper ingots. As an advanced Ingot Casting Machine, it integrates seamlessly into the Copper Ingot Production Line, ensuring a streamlined process from start to finish. This Ingot Making Line is specifically designed to handle the complexities of copper casting with precision and reliability. The Copper Casting Machine excels in delivering consistent results, thanks to its advanced technology and engineering. It effectively manages the molten copper, controlling the temperature and flow to produce uniform ingots. Its robust design and sophisticated control systems ensure that the Brass Ingot Production Line operates efficiently, whether producing brass or copper ingots. With its state-of-the-art features, this machine provides enhanced performance and reliability, reducing operational costs and improving overall production efficiency. It is an essential component for any facility aiming to achieve high standards in ingot production, making it a top choice for both Copper Ingot Production Line and Ingot Making Line applications. |

Product Introduction

The original design of this machine is suitable for copper ingot and aluminum ingot.

Product Size

name | quantity | Value |

main motor | 1 | 4kw 4 grade |

Pit wheel | 1 | B2X160 |

Pit belt | 2 | |

Connector | 2 | 1.2 inch 22 teeth |

Reduction gearbox | 1 | Xwe63-253 double stage |

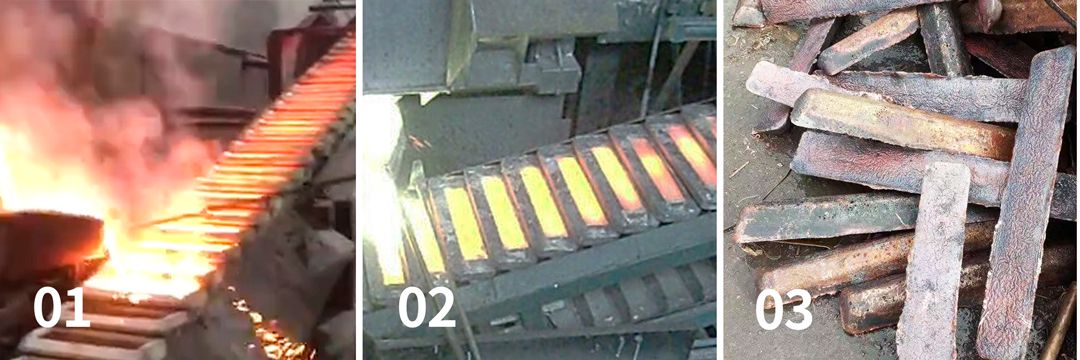

Detailed images