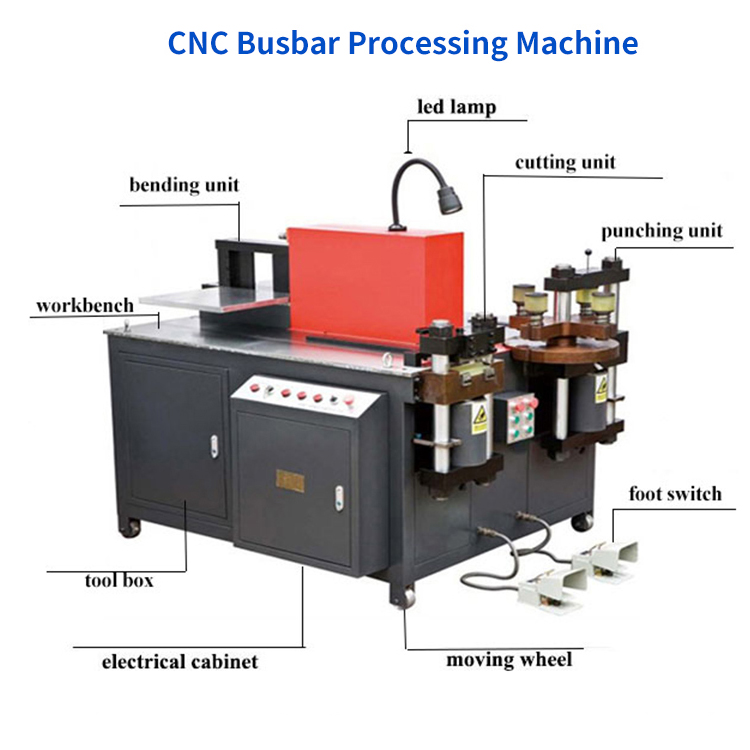

This series copper busbar bender has three units:punching, shearing and bending.It is easily to adjust each unit to shorten the processing time and improve the production efficiency. It is used to process copper busbars and aluminum busbars in different specification.By relative operation unit It can easily and quickly do all kinds of processing to copper busbars and aluminum busbar,such as shearing, punching (circular hole and oblong hole), flat/honrizental bending, vertical bending and knurling.Change differentmold to do special processing to copper bar,such as flat press,embossing,cable connector process,and can do cutting,flat crushing,pushing,and bending.

Standard configuration | |

Product model name | Bus processing machine DXJ-303ESKK |

Dimensions (mm) length * width * height | 1760mm×1400mm×1300mm |

weight | 1400kg |

Second floor workbench | 1100mm×900mm |

First floor workbench size | 1760mm×1250mm |

Maximum cutting thickness/width | 12mm/150mm |

Maximum thickness/width | 12mm/150mm |

Maximum thickness/width of bending | 10mm/100mm |

Punching diameter | Φ4.3≈Φ30 |

1.

2. Rotary turret punch unit installed 6 dies, less replacing, high efficiency

3. More work space added by double work table, three work positions can be used at the same time.

4. Controlled by PLC, bending precision at ±1 degree and repeat degree at ±0.3 degree

5. Easily to be moved with four castors

6. Manual button and foot switch are optional

7. Adjustable working stroke

8. on users requirement, special mold for special shape