◆Fully enclosed circulating cooling to prevent pipeline blockage caused by debris

◆Using soft water circulating cooling to prevent overheating damage to the power supply, SCR, capacitor, IGBT module, induction coil, etc. caused by the formation of scale.

◆High heat dissipation efficiency and low operating cost.

◆No need to dig a pool, small footprint, convenient movement and lower cost.

◆The closed circulating water consumption is small, which meets the requirements of environmental protection and energy saving.

◆The traditional way of cooling high, intermediate frequency and super audio frequency induction equipment is to excavate a certain size pool or use a scattered cooling water tower, directly cooling with hard water, often because of poor water quality, the water pipe wall is scaled, causing The circulating water flow is gradually reduced or even blocked, causing damage to components (for example: electron tubes, thyristors, reactors, capacitors, IGBT modules, induction coils), etc.

◆In our company's maintenance of medium and high frequency induction heating equipment, it is concluded that equipment failures caused by water account for about 80% of equipment damage. Such as change

Introducing the quality of the cooling circulating water and fully cooling the equipment will reduce the equipment failure rate by 80%.

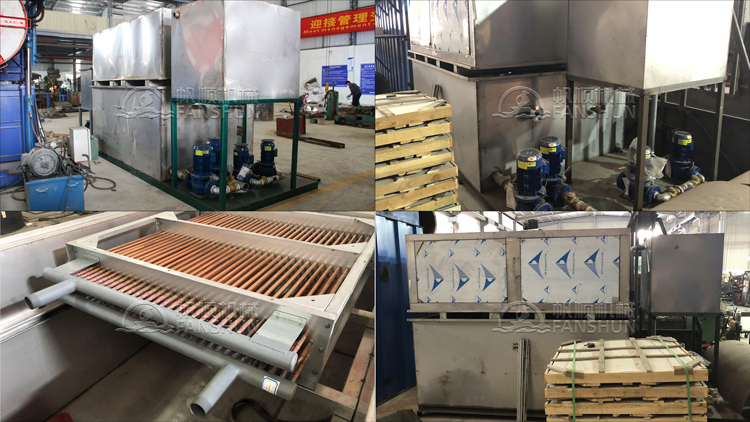

◆Our company successfully developed the FBN series closed water cooling system in response to the above problems