Metal smelting furnaces are indispensable tools in the process of extracting and refining various metals. These Metal smelting furnaces come in different types, each tailored to specific metal smelting needs. One such type is the traditional Metal smelting furnace, which plays a fundamental role in the extraction of metals from ores. The smelting process begins with loading raw materials into the smelting furnace. These materials can range from ores containing copper, iron, or other metals to scrap metal for recycling. Once the furnace is loaded, it is heated to extremely high temperatures, causing the metal within to melt. Among the various types of smelting furnaces, the copper melting furnace is particularly significant in the production of copper.The copper melting furnace is a vital component in the metallurgical industry. This copper melting furnace is designed to melt down copper ores or scrap copper, separating the metal from impurities and allowing it to be poured into molds for further processing. Electric smelting furnaces represent a modern approach to metal smelting, utilizing electricity as the primary heat source. These Electric smelting furnaces offer greater control over temperature and energy efficiency compared to traditional fuel-fired furnaces. Electric smelting furnaces are commonly used in the smelting of various metals, including aluminum and steel. Similarly, iron smelting furnaces are essential for the production of iron and steel. Iron smelting furnaces utilize coke or coal as fuel to reach the high temperatures required to melt iron ore and extract the metal. Iron smelting furnaces come in different designs, such as blast furnaces or direct reduction furnaces, each suited to specific iron smelting processes. In summary, metal smelting furnaces play a crucial role in the production of various metals, from copper and iron to aluminum and steel. Whether it's traditional smelting furnaces, copper melting furnaces, electric smelting furnaces, or iron smelting furnaces, each type serves a specific purpose in the extraction and refinement of metals, contributing to industries worldwide. |

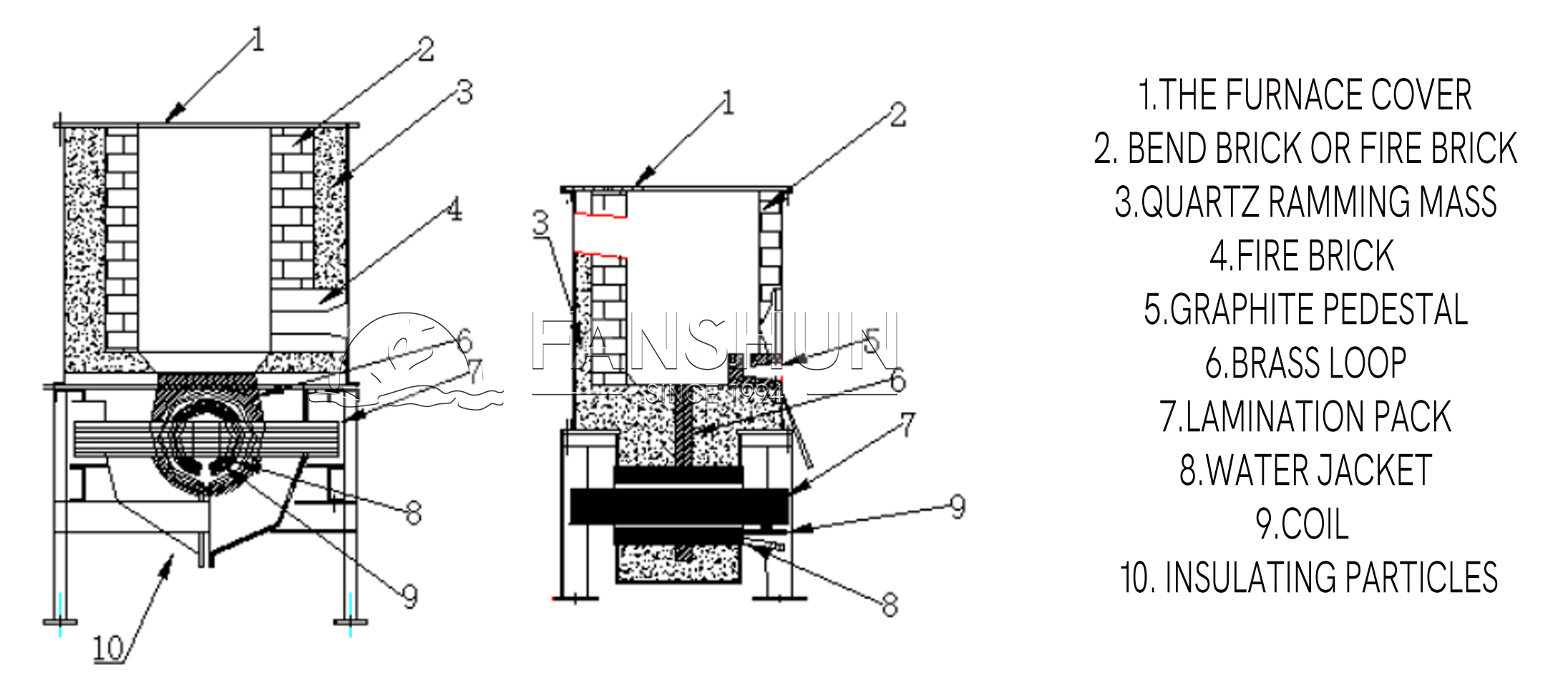

Products Description

Product Size

| Model | Unit | GYT-300 | GYT-500 | GYT-750 | GYT-1000 | GYT-1500 |

| Rated Power | kw | 75 | 120 | 180 | 240 | 360 |

| Rated Voltage | v | 380 | ||||

| Phases | / | 3 | ||||

| Frequency | hr | 50 | ||||

| Power Factor | / | 0.95 | ||||

| Maximum Melting Temperature | ℃ | BRASS:1080/copper:1350 | ||||

| Melting Rate | kg/h | copper:300 brass:400 | copper:500 brass:600 | copper:600 brass:700 | copper:900 brass:1000 | copper:1500 brass:1800 |

| Power Consumption | kwh/t | 250-300 | ||||

| Number Of Channels | piece | 1 | 1 | 2 | 2 | 2 |

| Cooling Method | / | air cooled/water cooling | ||||

Detailed images