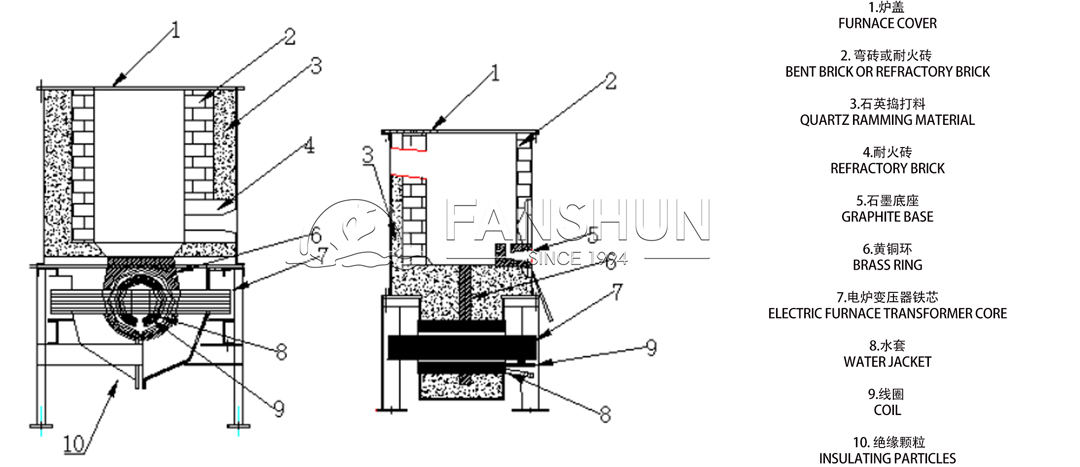

The Brass bar smelting furnace holding furnace is a critical component in the process of producing brass bars. Brass bar smelting furnace holding furnace serves as a holding vessel for the molten brass after Brass bar smelting furnace has been smelted in an induction melting electric furnace or an electric arc furnace. This Brass bar smelting furnace holding furnace ensures that the molten brass remains at the optimal temperature for casting or further processing. Induction melting electric furnaces are commonly used in the initial smelting stage to melt brass scrap or raw materials. These Induction melting electric furnaces utilize electromagnetic induction to generate heat within the metal, allowing for efficient and precise melting. The molten brass is then transferred to the holding furnace for temperature regulation and storage. In some cases, brass may also be produced in a blast furnace, particularly in large-scale foundries. Blast furnaces are capable of smelting a wide range of metals, including brass, by using high temperatures and a forced air or oxygen blast to facilitate combustion and melting. Foundry furnaces play a crucial role in the brass production process by providing the necessary heat for melting and shaping metal. These Foundry furnaces come in various designs, including cupolas and reverberatory furnaces, and are often used in conjunction with holding furnaces to ensure continuous production and consistent quality. Electric arc furnaces represent another method of brass production, particularly in recycling operations. These Electric arc furnaces use an electric arc to generate heat and melt scrap brass, contributing to sustainable manufacturing practices by reusing materials.Electric arc furnace plays a crucial role in continuous production processes, facilitating efficient and consistent copper melting operations. In summary, the production of brass bars involves the use of various furnaces, including Brass bar smelting furnace ,holding furnace induction melting electric furnaces, blast furnaces, foundry furnaces, and electric arc furnaces. These furnaces work in tandem to smelt, hold, and shape molten brass, ensuring efficient production processes and high-quality end products. The brass bar smelting furnace holding furnace serves as a vital component in this process, providing temperature control and storage capabilities for the molten brass, contributing to the overall success of brass manufacturing operations. |

Products Description

Product Size

| Model | Unit | GYT-300 | GYT-500 | GYT-750 | GYT-1000 | GYT-1500 |

| Rated Power | kw | 75 | 120 | 180 | 240 | 360 |

| Rated Voltage | v | 380V | ||||

| Number of phases | / | 3 | ||||

| Power | hz | 50 | ||||

| Maximum melting temperature | ℃ | Brass 1080/Copper 1350 | ||||

| Melting rate | kg/h | Copper 300 | Copper 500 | Copper 750 | Copper 1000 | Copper 1500 |

| Brass 400 | Brass 650 | Brass 900 | Brass 1200 | Brass 1800 | ||

| Power consumption | kwh/t | 250-300 | ||||

| Number of molten grooves | pcs | 1 | 1 | 2 | 2 | 2 |

| Cooling method | / | water cooling/air cooling | water cooling | |||

| Furnace weight | kg | 3500 | 5000 | 5500 | 6000 | 7000 |

| Holding furnace weight | kg | 3500 | 5500 | 5500 | / | / |

| Electric cabinet shape | m | 1*0.8*2 | 1*0.6*2 | 1*0.6*2 | 1*0.6*2 | 1.2*1*2 |

Product comparison before and after melting