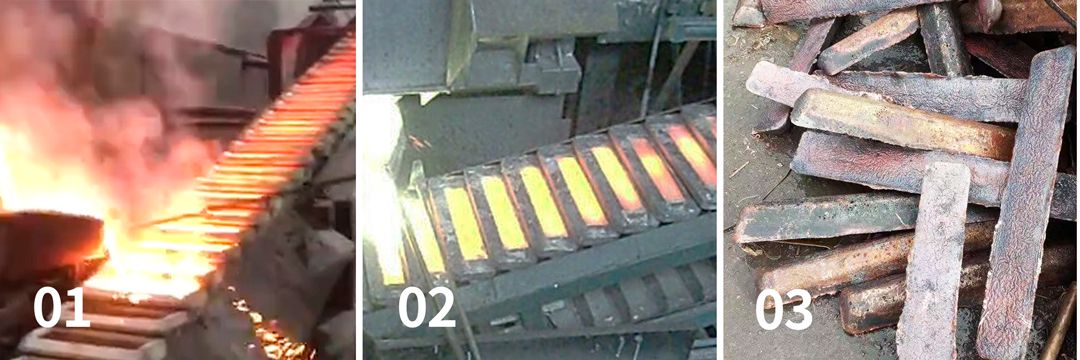

| Aluminium ingot casting, Ingot Casting Machine, Continuous Up Drawing Melting Furnace, aluminum ingot casting machine, and Lead Casting Equipment are fundamental elements in the aluminum and lead industries. These technologies are essential for the efficient production and processing of aluminum and lead materials, serving various industrial applications. The process begins with aluminium ingot casting, where molten aluminum is solidified into ingots, providing a primary form for further processing. Ingot Casting Machines are employed to streamline this process, ensuring precision and consistency in ingot formation. Simultaneously, Continuous Up Drawing Melting Furnaces maintain a continuous supply of molten aluminum, supporting uninterrupted production cycles. Within this framework, aluminum ingot casting machines play a pivotal role in shaping ingots into desired dimensions, catering to specific industry requirements. Additionally, Lead Casting Equipment facilitates the casting of lead materials, offering similar functionalities and benefits within the lead manufacturing sector. Together, these technologies form an integrated system, driving productivity, quality, and innovation in the aluminium and lead industries, while also contributing to sustainability through efficient resource utilization. |

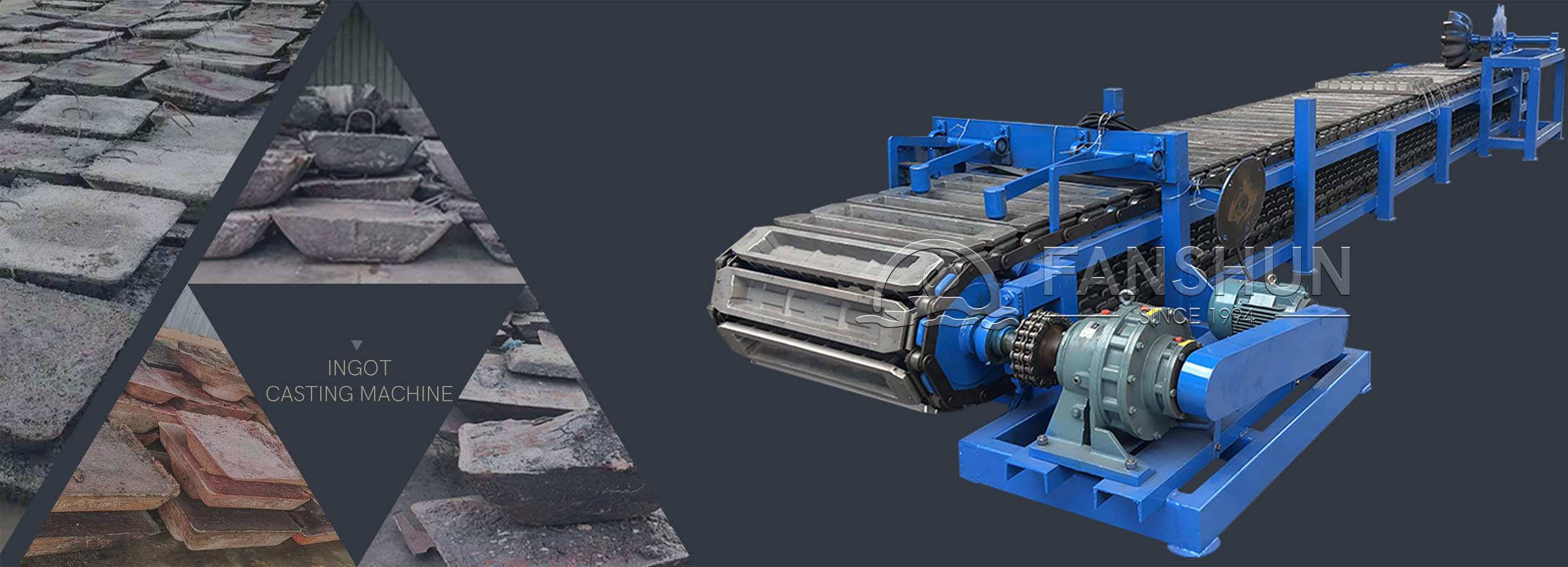

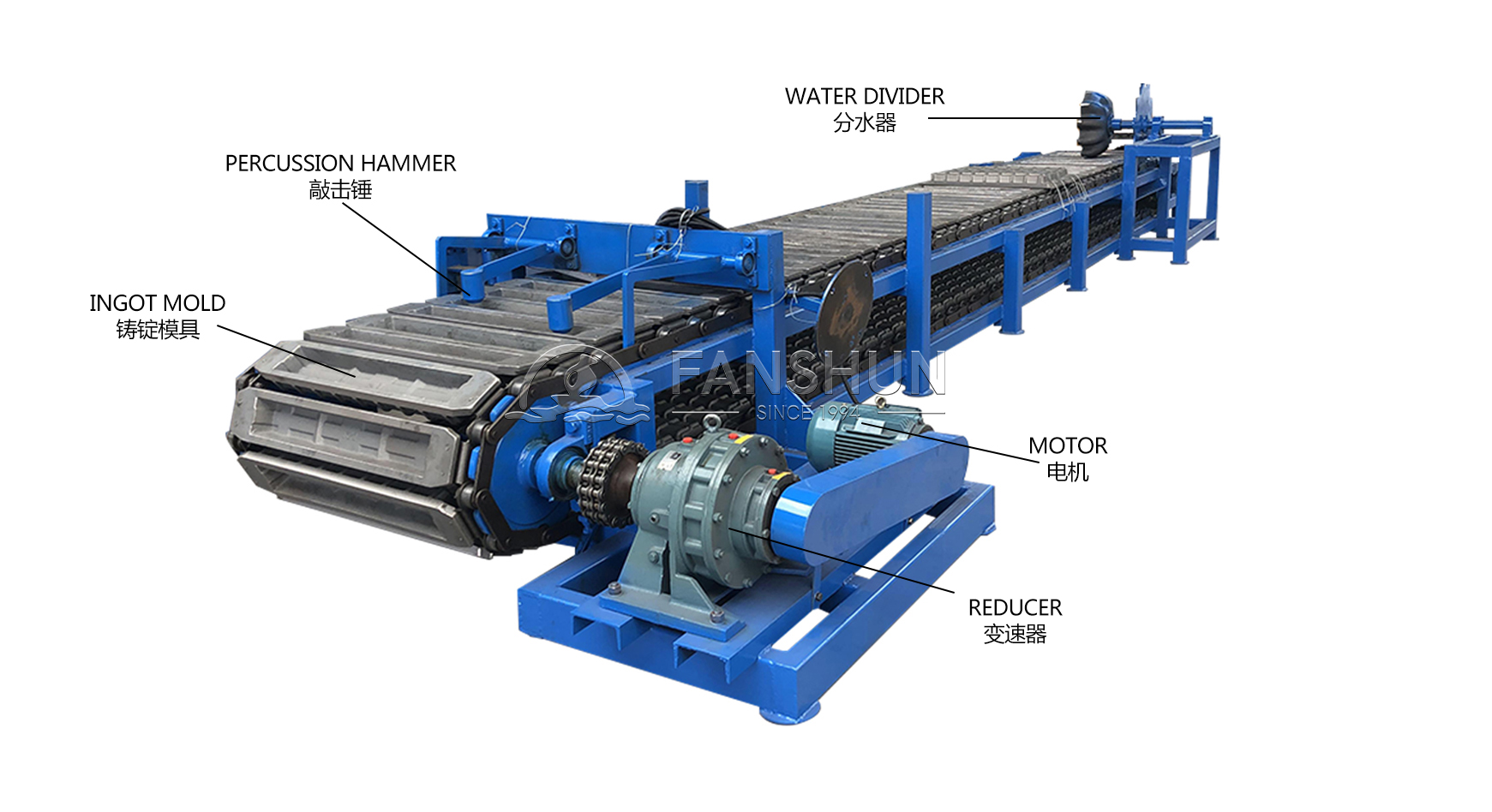

Product Illustration

name | quantity | Value |

main motor | 1 | 4kw 4 grade |

Pit wheel | 1 | B2X160 |

Pit belt | 2 | |

Connector | 2 | 1.2 inch 22 teeth |

Reduction gearbox | 1 | Xwe63-253 double stage |

Product comparison before and after casting

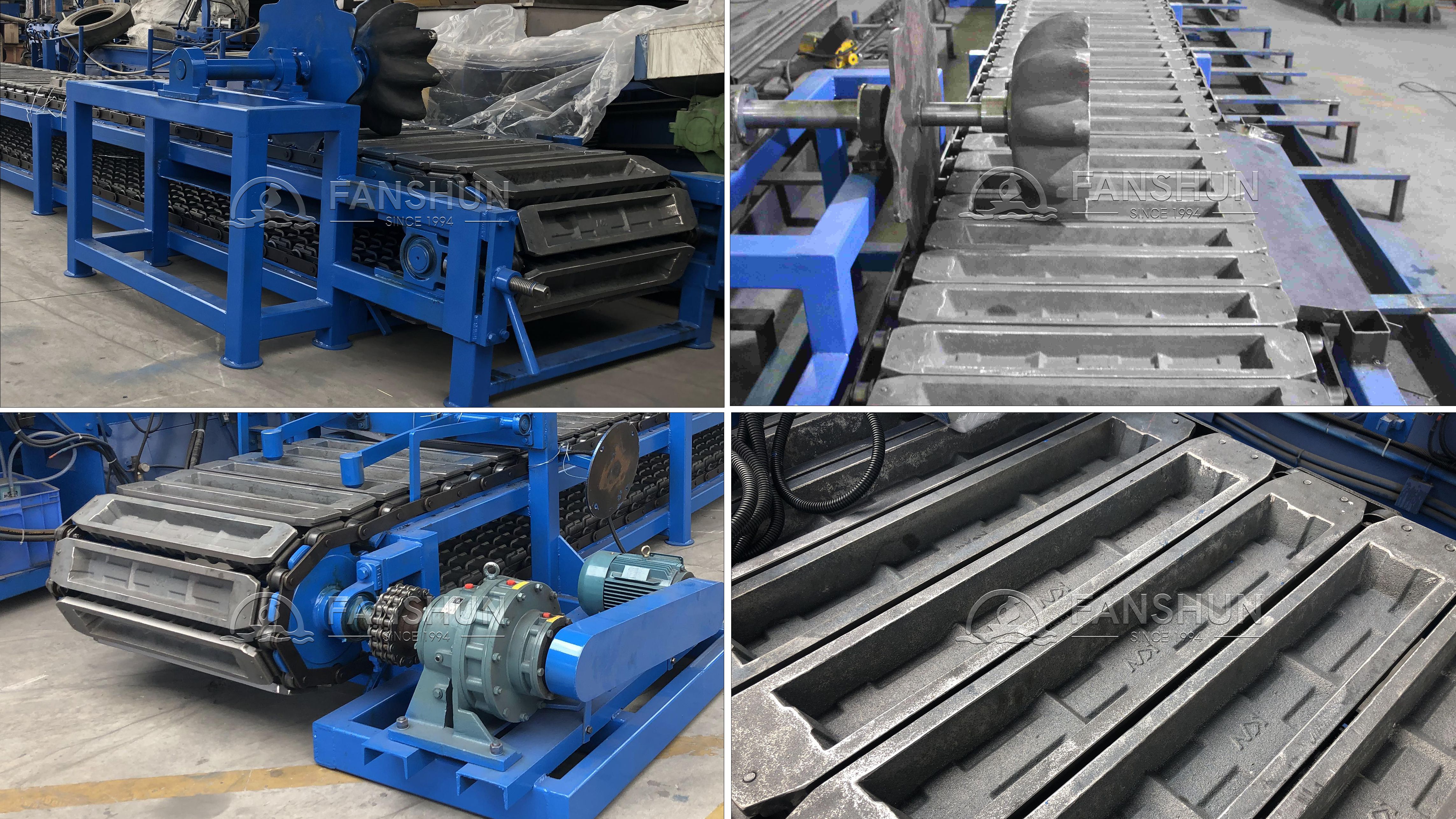

Detailed images