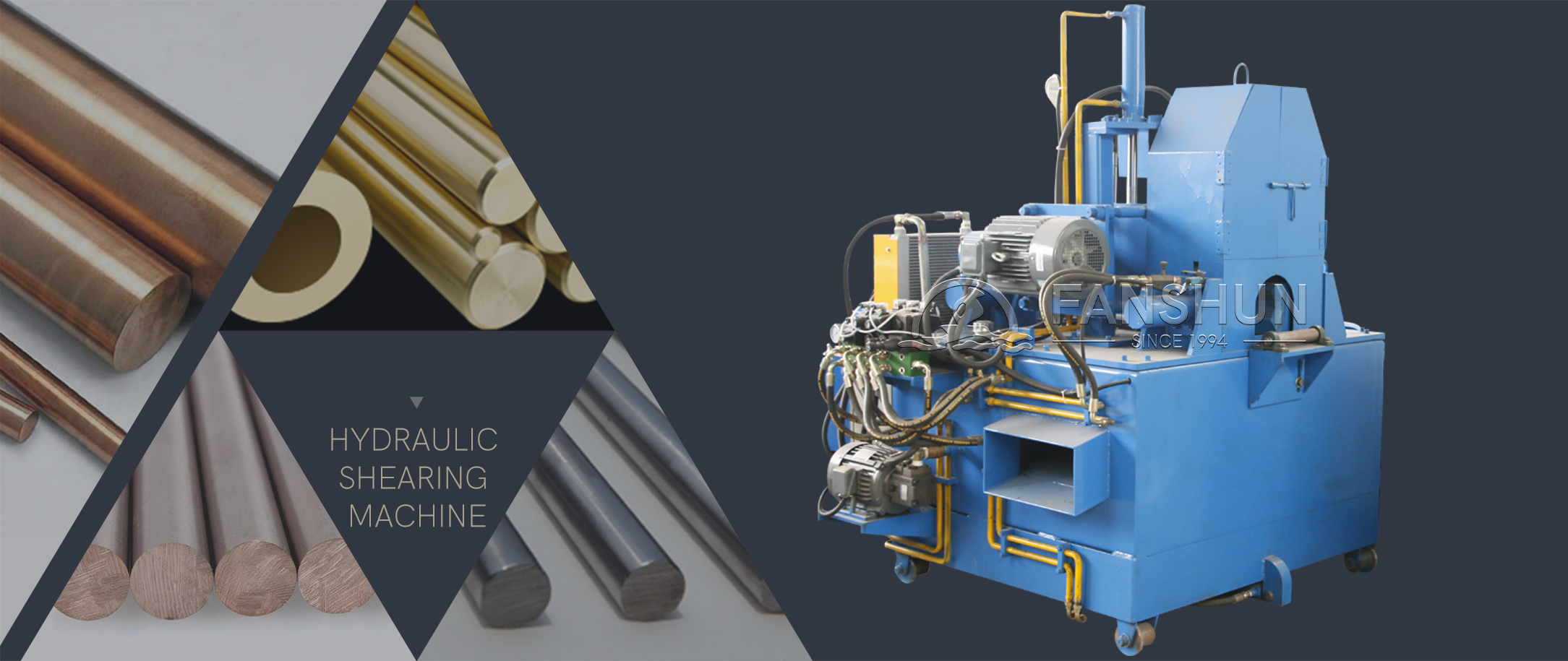

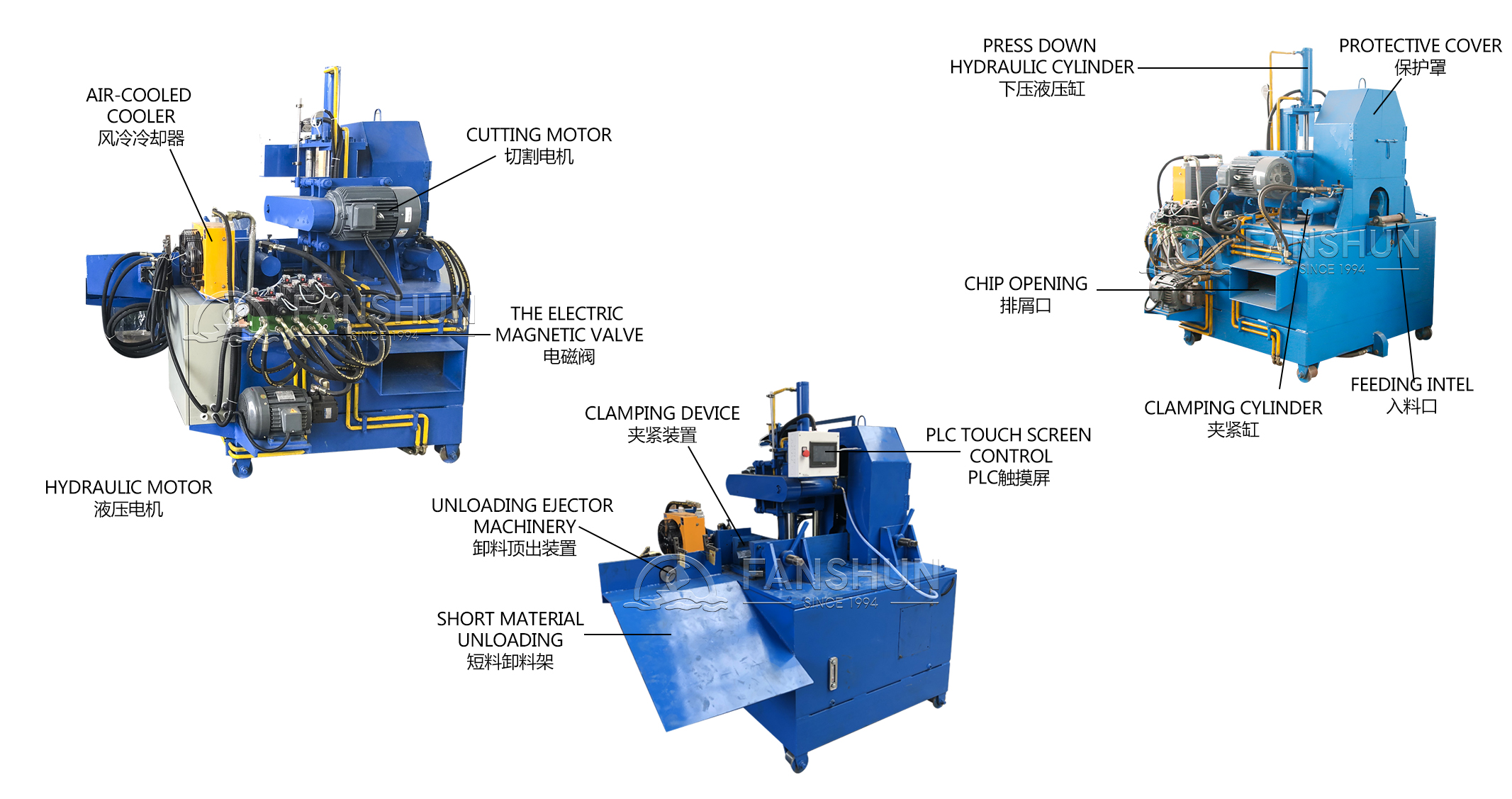

The heavy metal bar cutting machine is a critical tool in the metalworking industry, designed to handle the demanding task of cutting large and heavy metal bars. This heavy metal bar cutting machine combines efficiency and precision, making it an essential asset for manufacturers dealing with various metal cutting needs. In this article, we will explore the features and benefits of the heavy metal bar cutting machine, while highlighting related equipment such as the rod cutting machine, hydraulic cutting, automatic bar cutting machine, round bar cutting machine, and metal bar cutter. Key Features of the Heavy Metal Bar Cutting MachineThe heavy metal bar cutting machine is engineered to cut through large and heavy metal bars with precision and ease. This heavy metal bar cutting machine is built to handle high volumes of cutting operations, making it ideal for heavy-duty applications. The heavy metal bar cutting machine typically features robust construction, high cutting power, and advanced controls to ensure accurate and clean cuts. The heavy metal bar cutting machine can be used for various types of metal bars, including steel, aluminum, and other alloys, positioning it as a versatile metal bar cutter. Rod Cutting Machine: Essential ComponentThe rod cutting machine is a specific type of equipment used for cutting metal rods, rod cutting machine often processed by the heavy metal bar cutting machine. The rod cutting machine typically features specialized blades and mechanisms to handle different rod diameters and materials. While the rod cutting machine is designed for smaller-scale cutting tasks, the heavy metal bar cutting machine addresses more extensive and heavier cutting needs, showcasing its superiority over a standard metal bar cutter. Hydraulic Cutting: Advanced TechnologyHydraulic cutting technology plays a crucial role in the operation of the heavy metal bar cutting machine. Hydraulic cutting systems provide the necessary force to cut through tough metals with ease and accuracy. The use of hydraulic cutting ensures that the heavy metal bar cutting machine operates smoothly and efficiently, delivering consistent performance across various cutting tasks. This hydraulic cutting mechanism is essential for maintaining the machine's effectiveness as a reliable metal bar cutter. Automatic Bar Cutting Machine: Enhanced EfficiencyThe automatic bar cutting machine represents an advanced version of the traditional cutting machine, incorporating automation to streamline the cutting process. Automatic bar cutting machine with features such as programmable controls and automated feeding systems, the automatic bar cutting machine enhances efficiency and reduces manual labor. This type of automatic bar cutting machine is particularly useful in high-volume production environments, where speed and precision are critical, adding to the capabilities of the heavy metal bar cutting machine as an efficient metal bar cutter. Round Bar Cutting Machine: Specialized FunctionalityThe round bar cutting machine is designed specifically for cutting round metal bars. While the heavy metal bar cutting machine can handle various shapes and sizes, the round bar cutting machine focuses on providing precise cuts for round bars. This round bar cutting machine is essential for applications where round metal bars are a primary material, ensuring accurate and clean cuts every time. Round bar cutting machine integration with a heavy metal bar cutting machine further enhances its role as a specialized metal bar cutter. ConclusionThe heavy metal bar cutting machine is an essential piece of equipment for handling large and heavy metal bars with precision and efficiency. By incorporating advanced technologies such as hydraulic cutting and automation, the heavy metal bar cutting machine ensures high performance in demanding cutting applications. Understanding the roles of related equipment, including the rod cutting machine, automatic bar cutting machine, round bar cutting machine, and metal bar cutter, highlights the versatility and importance of cutting machines in the metalworking industry. Investing in the right heavy metal bar cutting machine and metal bar cutter ensures optimal performance and enhances productivity in metal processing operations. |

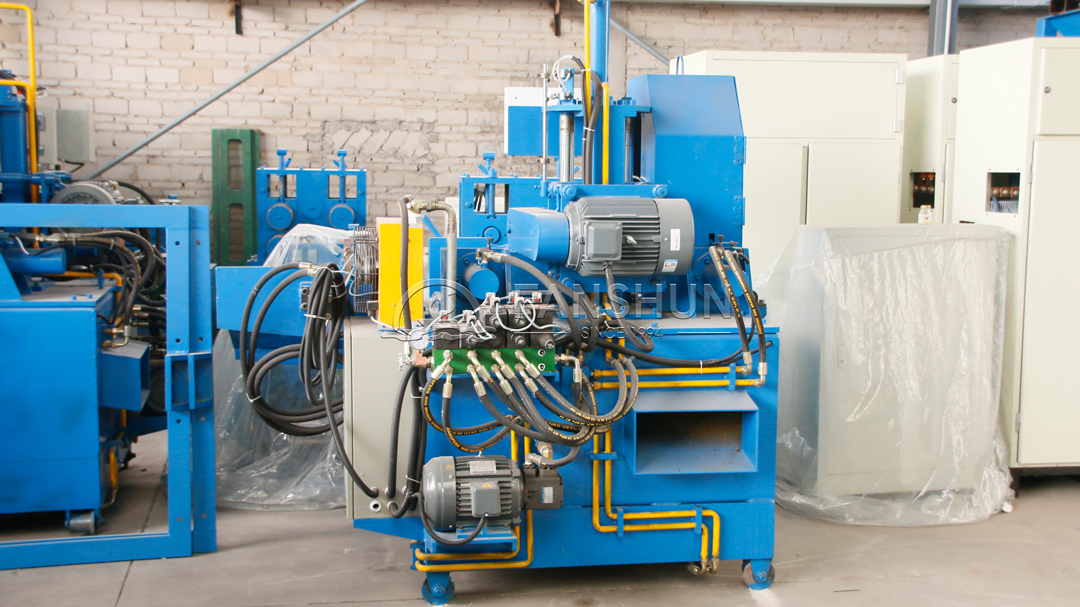

Products Description

Product Size

Sawing cross-sections possible | Φ60~Φ160 |

Cutting motor power | 7.5kw 4 poles |

Hydraulic station motor power | 2.2KW 4 poles |

Clamping cylinder × 2 | 80X100 |

Feeding Cylinder | 63X250 |

carriage return cylinder | 55X850 |

Hydraulic Solenoid Valve | 03-3C2 ,03-2B3B,03-2B2 |

Alloy saw blade | 500 |

Product comparison before and after cutting