The Horizontal Rotary Melting Furnace operates through horizontal rotation, which is crucial for its effectiveness as a Rotary aluminum melting furnace. This rotation ensures even heat distribution and thorough mixing of molten aluminum, critical for maintaining high-quality melts. The furnace’s design allows it to function optimally as an Aluminum rotary furnace, delivering consistent performance across various aluminum melting processes.

In addition to being a Rotary aluminum melting furnace, the Horizontal Rotary Melting Furnace is also versatile enough to serve as a Rotary melting furnace for other metals, including copper. This dual functionality enhances its value in metal processing industries.

Uniform Melting: The horizontal rotation of the Rotary aluminum melting furnace ensures even heating and mixing, crucial for high-quality aluminum processing.

Efficiency: The Horizontal Rotary Melting Furnace improves energy efficiency and reduces melting time, benefiting its role as an Aluminum rotary furnace.

Versatility: Functions effectively as both a Rotary aluminum melting furnace and a Copper melting furnace, making it adaptable for different applications.

High Quality: Produces superior melts with minimal impurities, essential for both the Rotary aluminum melting furnace and other metal processing tasks.

The Horizontal Rotary Melting Furnace is extensively used in various industrial sectors:

Aluminum Processing: Primarily serves as a Rotary aluminum melting furnace for producing aluminum alloys and recycling.

Copper Processing: Functions as a Copper melting furnace, suitable for refining and alloy production.

Die Casting: Utilized as a die casting electric furnace for producing high-quality die-cast components.

In summary, the Horizontal Rotary Melting Furnace is a highly efficient and versatile tool, excelling as both a Rotary aluminum melting furnace and an Aluminum rotary furnace. Its advanced design ensures uniform melting and high-quality results for aluminum and other metals, making it indispensable in industrial applications.

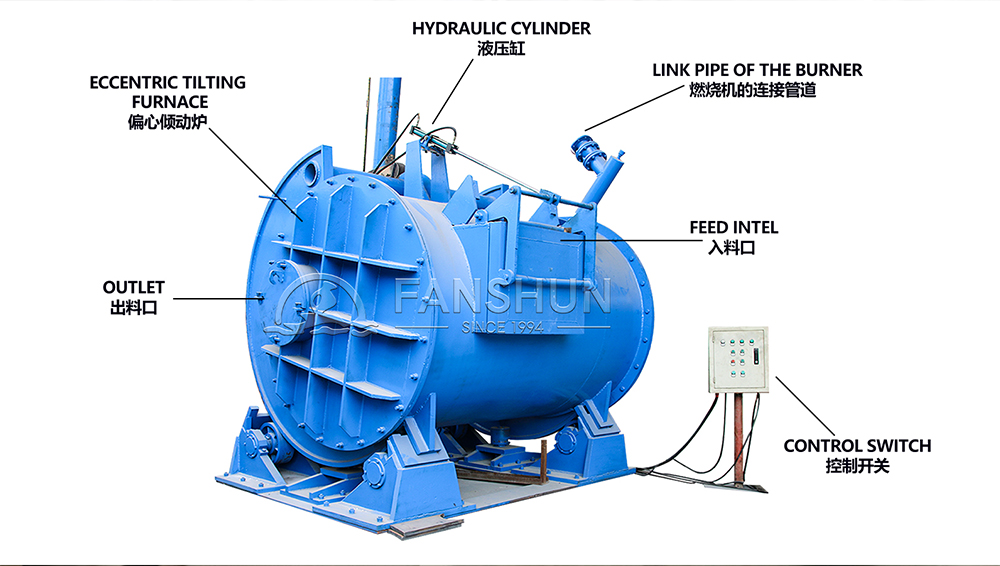

Products Description

Product Size

| ROTATION ANGLE | 90° | |||

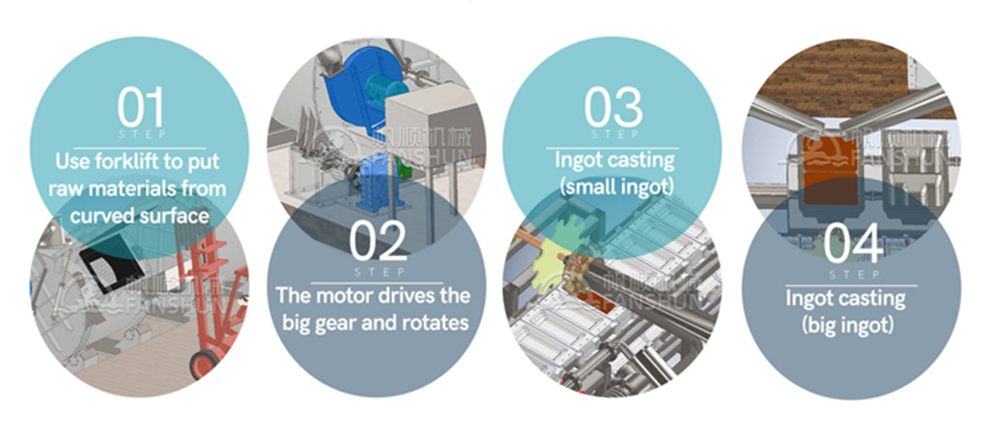

| SLEWING MECHANISM | The motor drives big gear | |||

| RAW MATERIALS | Lead, brass, copper, pure aluminum, aluminum alloy | |||

| MATERIAL LOSS | 1T battery waste 600kg-650kg lead ingotPure copper: 0.5% -1% or less | |||

| BURNER POWER | 30KW/h | |||

| BURNER CALORIFIC VALUE | 500kg with 500,000 kcal burner1T with 1 million kcal burner2T with 1.5 million-2 million kcal burner | |||

| FUEL | Lead: coke, coalAluminum, copper: gas (natural gas, gas, liquefied petroleum gas), oil (diesel, gasoline, heavy oil)Electric furnace is recommended for brass because of its lower boiling point | |||

| FUEL LOSS | Burner to fuel loss 60-80kg / TNatural gas loss 60-80kg / m³10% coke for 1T lead | |||

| MELTING EFFICIENCY | Copper: 500KG, 1T, 2T / h | |||

| LENGTH, WIDTH AND HEIGHT | 3T:2800*2000*1900 6T:3410*2212*2640 10T:5100*2212*2640 | |||

Product comparison before and after smelting

Detailed images