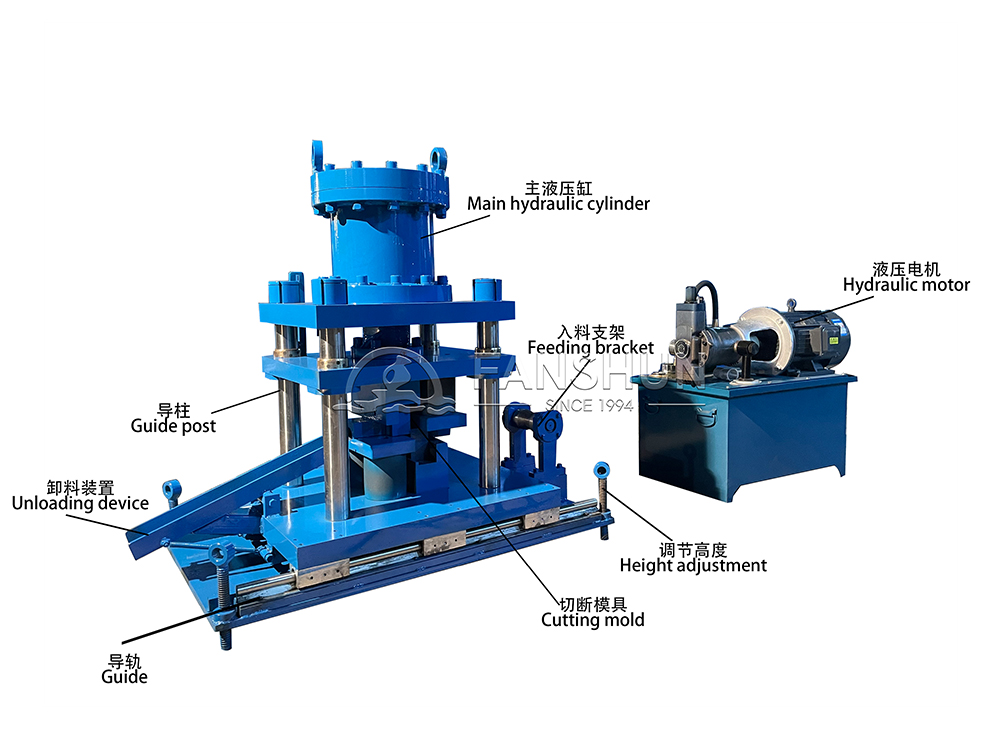

1. The main frame is placed corresponding to the center line position. The guide wheel is the inlet, and the leakage slot is the discharge port. The four-side adjustment screw is used to adjust the height.

2. Oil station fuel tank, add hydraulic oil (68#) to the dipstick 3 minutes 2, according to the motor 7.5kw corresponding to the power cord and switch, the steering is correct.

3. Through adjustment, manual debugging, upper and lower limit, pressure (about 110-120), if the pressure is insufficient, it can be increased to 130 kg.

4. Note that the upper and lower knives meet the required clearance of 0.3-0.4mm.

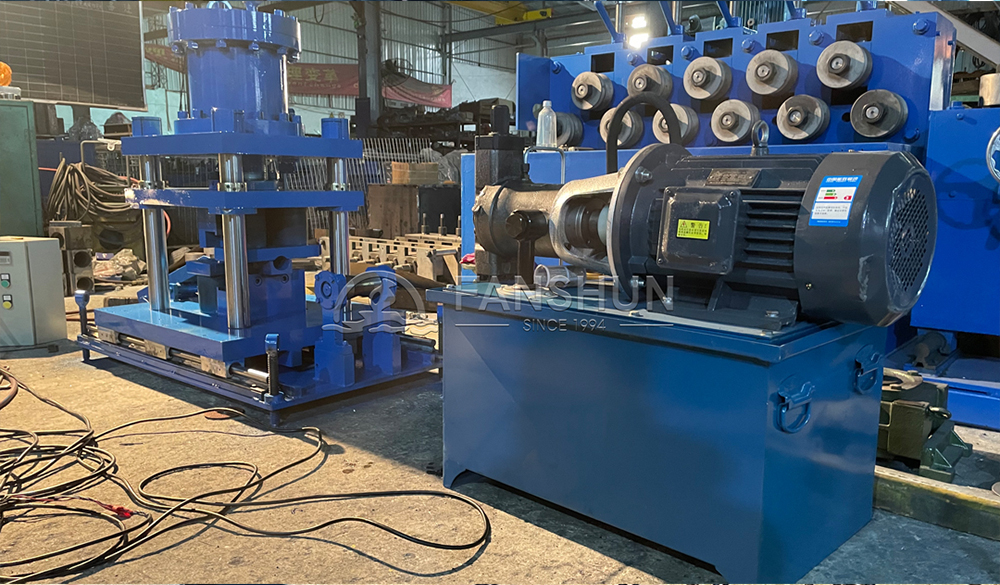

5. Install an inductive switch to the side of the rocker arm of the casting machine to use as the control signal for each number of moving teeth, and cut it (the length of the bar is determined by the number of moving teeth)

6. After the above device is completed, it can be energized, the machine casting action experiment, adjust the digital table value on the electric box, try the length effect, and then the automatic operation can be performed.