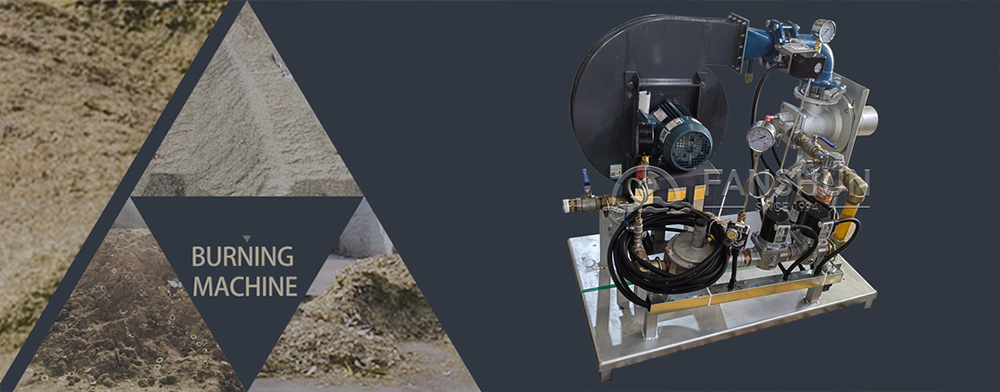

The need for efficient and environmentally friendly combustion solutions is more pressing than ever in today's industrial landscape. With increasing regulations and a growing focus on sustainability, industries are looking for innovative ways to reduce emissions without sacrificing performance. The Integrated Low Nitrogen Burner is a cutting-edge solution that addresses these challenges by significantly reducing nitrogen oxide (NOx) emissions, making it an ideal choice for industries that rely heavily on combustion processes. This article will explore the benefits and features of integrated low nitrogen burners, while also discussing related technologies such as natural gas burners, burner management systems like Burnerapp, natural gas production equipment, and gas industrial burners. Integrated Low Nitrogen Burner: A Sustainable SolutionThe Integrated Low Nitrogen Burner is designed to minimize the production of nitrogen oxides (NOx), which are harmful pollutants that contribute to smog and acid rain. NOx is typically produced during the high-temperature combustion of fossil fuels, making Integrated Low Nitrogen Burner a significant concern for industries that rely on large-scale burners. The integrated low nitrogen burner achieves low NOx emissions by incorporating advanced combustion techniques, such as staged combustion, flue gas recirculation, and optimized air-fuel mixing. These features not only reduce NOx emissions but also enhance overall burner efficiency, leading to cost savings and improved performance. Natural Gas Burner: Efficiency and Clean EnergyThe natural gas burner is a key component in many industrial processes, known for its high efficiency and cleaner combustion compared to other fossil fuels. Natural gas burns more cleanly than coal or oil, producing fewer pollutants such as carbon dioxide (CO2), sulfur dioxide (SO2), and particulate matter. When combined with an integrated low nitrogen burner, the use of natural gas becomes even more environmentally friendly. The low NOx technology further reduces the environmental impact, making it an excellent choice for industries seeking to lower their carbon footprint while maintaining high operational efficiency. Burnerapp: Advanced Burner ManagementBurnerapp is an example of modern burner management software that enhances the functionality and safety of industrial burners, including integrated low nitrogen burners. This type of software allows for real-time monitoring and control of burner operations, ensuring optimal performance and safety. Burnerapp can manage multiple burners simultaneously, adjusting parameters such as air-to-fuel ratio, ignition timing, and temperature control. This level of control not only improves efficiency but also helps in maintaining compliance with stringent environmental regulations. Integration with burner management systems like Burnerapp makes the operation of low nitrogen burners even more effective and user-friendly. Natural Gas Production Equipment: Supporting Cleaner CombustionThe role of natural gas production equipment is critical in ensuring a steady and reliable supply of natural gas for industrial burners. This natural gas production equipment includes extraction, processing, and transportation systems that bring natural gas from the wellhead to the end-user. Advances in natural gas production technology have made it possible to deliver higher purity natural gas, which burns more cleanly and efficiently. When used in conjunction with an integrated low nitrogen burner, high-quality natural gas helps maximize combustion efficiency while minimizing emissions, creating a synergy that supports cleaner industrial processes. Gas Industrial Burners: Versatile and ReliableGas industrial burners are widely used across various industries due to their versatility, reliability, and high energy efficiency. These gas industrial burners can be adapted to burn different types of gases, including natural gas, biogas, and other industrial gases. The integration of low nitrogen technology into gas industrial burners is a significant advancement, as gas industrial burners allows for the reduction of NOx emissions across a broad range of applications. Gas industrial burners makes gas industrial burners equipped with low nitrogen technology ideal for industries such as power generation, chemical processing, and manufacturing, where both performance and environmental compliance are critical. ConclusionThe Integrated Low Nitrogen Burner represents a significant advancement in industrial combustion technology, offering a sustainable solution that reduces NOx emissions while maintaining high efficiency. When combined with natural gas burners, burner management systems like Burnerapp, and advanced natural gas production equipment, these burners provide a comprehensive approach to cleaner, more efficient industrial processes. As industries continue to prioritize environmental sustainability, the adoption of integrated low nitrogen burners is likely to become increasingly widespread, setting a new standard for industrial combustion technology. |

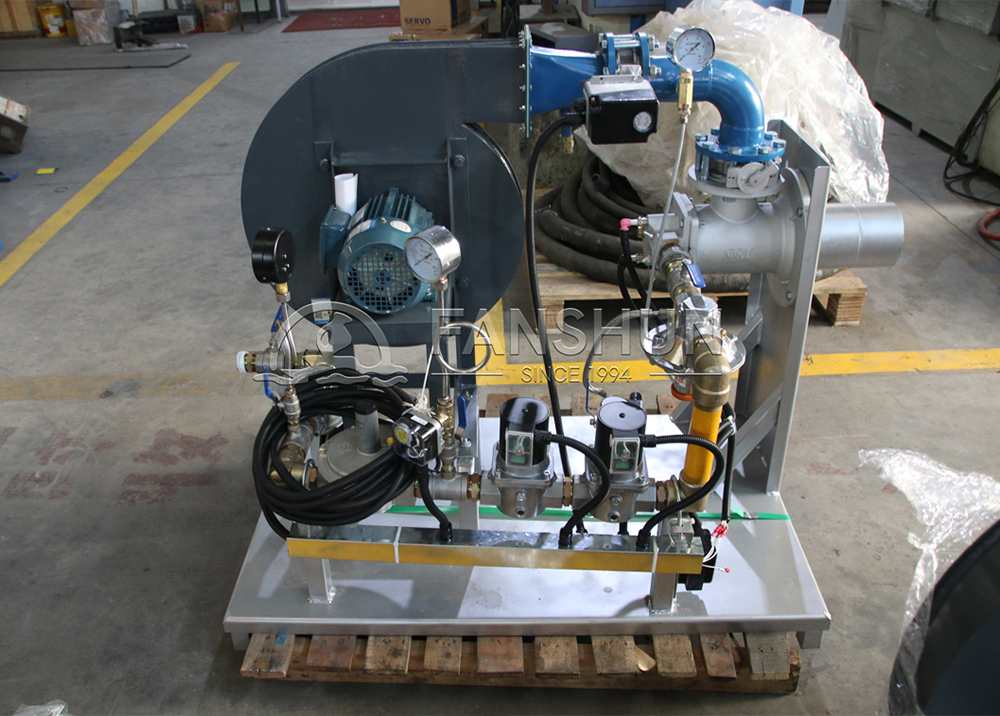

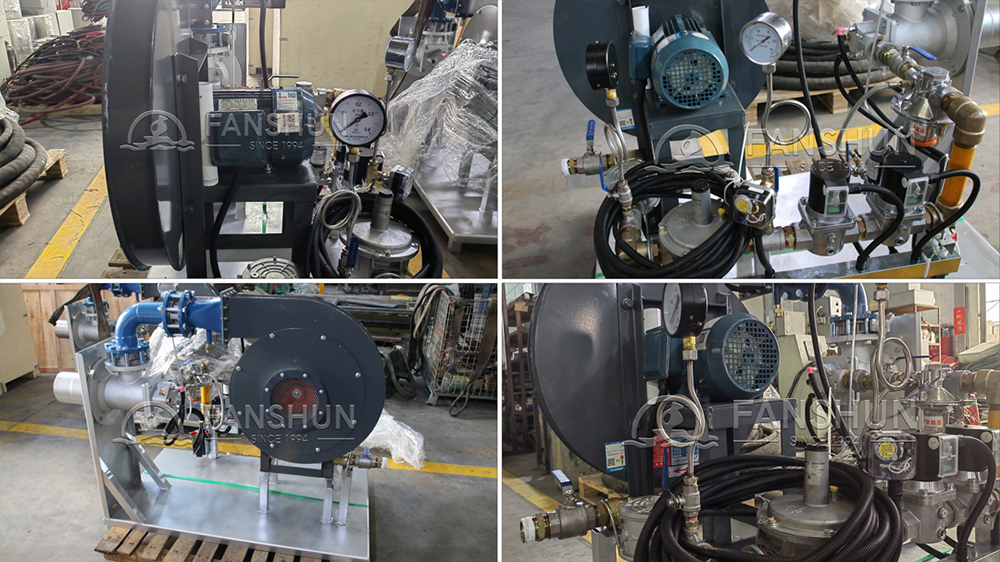

Products Description

Product Size

Detailed images