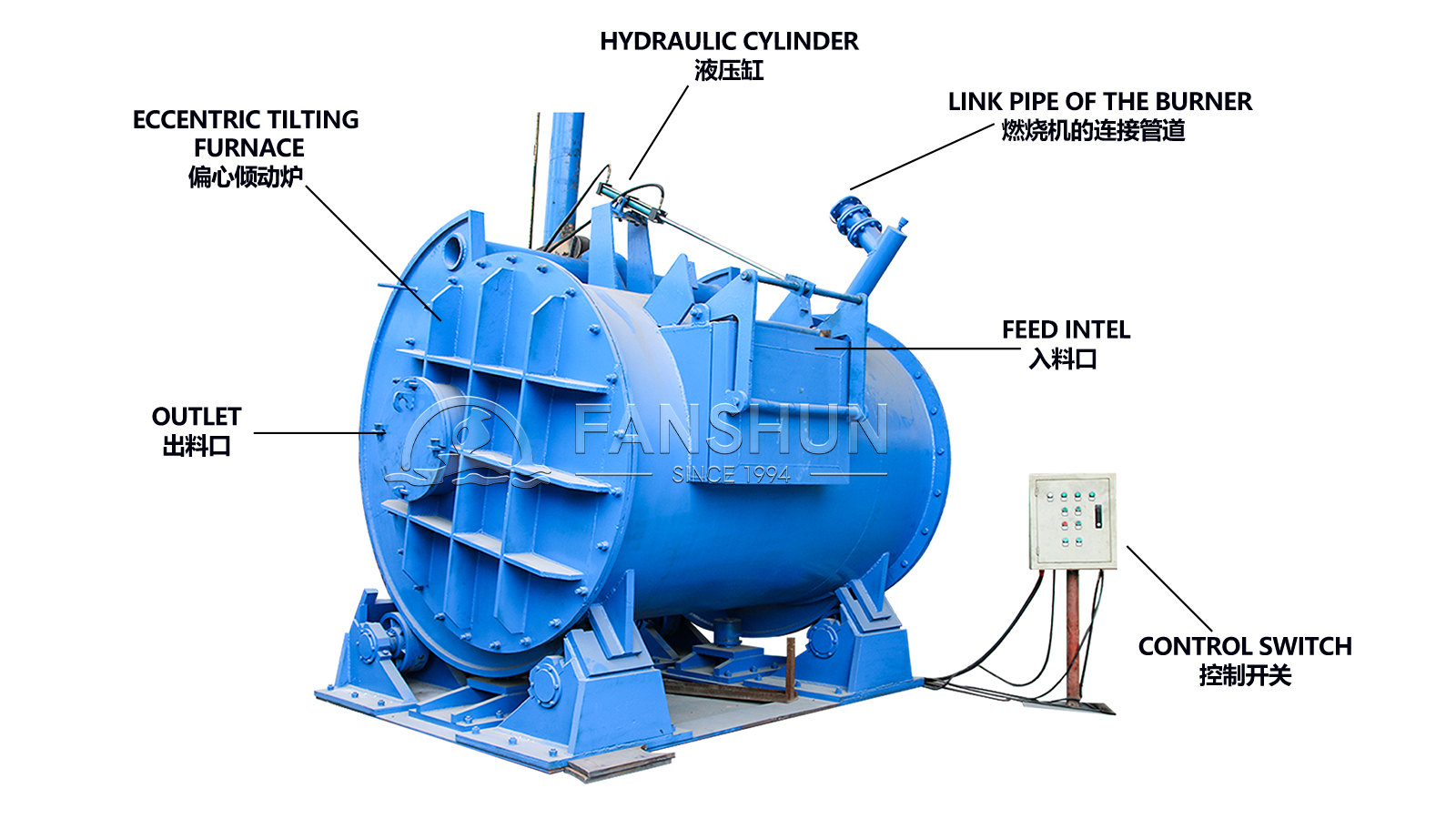

Product Size

| ROTATION ANGLE | 90° | |||

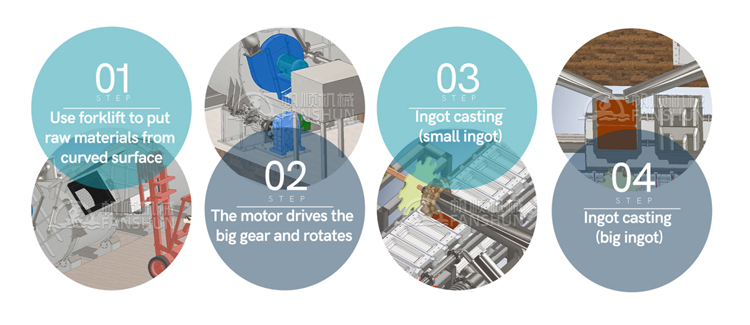

| SLEWING MECHANISM | The motor drives big gear | |||

| RAW MATERIALS | Lead, brass, copper, pure aluminum, aluminum alloy | |||

| MATERIAL LOSS | 1T battery waste 600kg-650kg lead ingotPure copper: 0.5% -1% or less | |||

| BURNER POWER | 30KW/h | |||

| BURNER CALORIFIC VALUE | 500kg with 500,000 kcal burner1T with 1 million kcal burner2T with 1.5 million-2 million kcal burner | |||

| FUEL | Lead: coke, coalAluminum, copper: gas (natural gas, gas, liquefied petroleum gas), oil (diesel, gasoline, heavy oil)Electric furnace is recommended for brass because of its lower boiling point | |||

| FUEL LOSS | Burner to fuel loss 60-80kg / TNatural gas loss 60-80kg / m³10% coke for 1T lead | |||

| MELTING EFFICIENCY | Copper: 500KG, 1T, 2T / h | |||

| LENGTH, WIDTH AND HEIGHT | 3T:2800*2000*1900 6T:3410*2212*2640 10T:5100*2212*2640 | |||

Product comparison before and after smelting

Detailed images