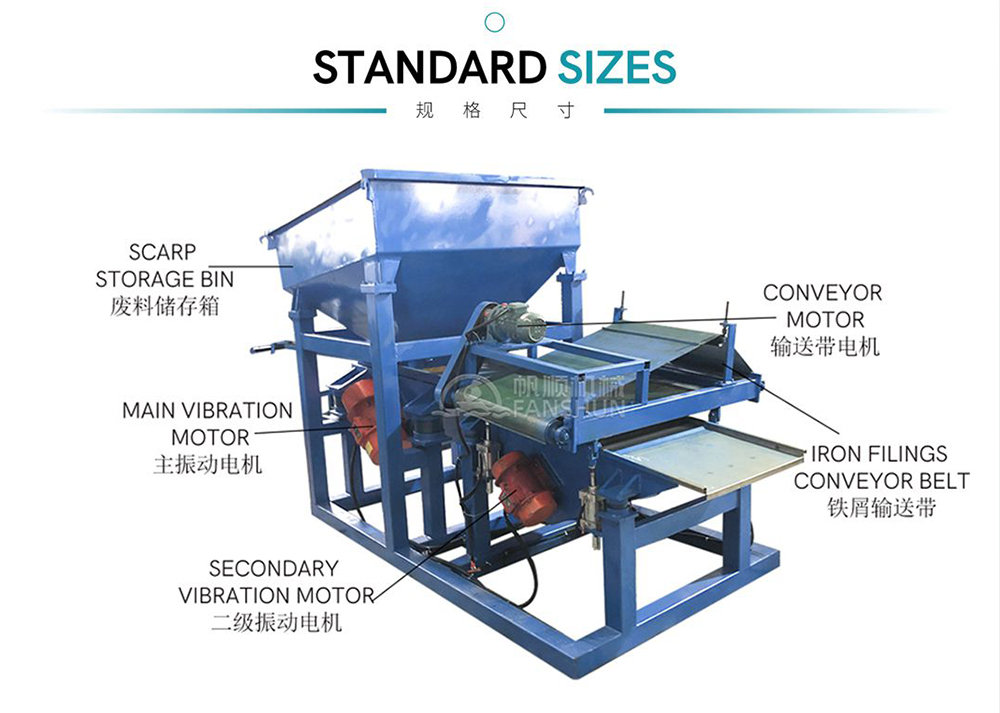

Product Size

A vibrating magnetic filter is an advanced solution designed to enhance magnetic filtration processes. Vibrating magnetic filter ’s primary function is to capture ferrous particles and contaminants from liquids, thus protecting equipment and improving magnetic filter system efficiency.

Working Principle: The magnetic filter system utilizes powerful magnets to attract and trap metal particles within the fluid. The magnetic filter system ensures that these particles are consistently agitated, which prevents clogging and facilitates their removal from the vibrating magnetic filter. The combination of magnetic strainer filter and boiler magnetic filter enhances the effectiveness of magnetic filtration, ensuring a cleaner and more efficient operation.

Advantages: This technology offers several key benefits. Magnetic filter significantly improves magnetic filtration efficiency by continuously removing metal contaminants, which reduces wear and tear on equipment. The magnetic filtration minimizes the risk of clogging and maintenance, while the magnetic filter system ensures even the smallest particles are captured. Additionally, magnetic strainer filter helps in extending the lifespan of system components and optimizing overall performance.

Applications: Vibrating magnetic filters are widely used in various industries. In boiler systems, they serve as a boiler magnetic filter. Boiler magnetic filter protecting against damaging ferrous particles. They are also valuable in HVAC systems, water treatment plants, and any application where fluid cleanliness is critical. By ensuring effective magnetic strainer filter operation, these magnetic filter systems contribute to improved system reliability and reduced downtime.

Overall, the vibrating magnetic filter is a vital component for efficient magnetic filtration and effective contamination control across multiple industrial applications.

Conveyor Magnetic Separator / Metal Recycling/ Iron Removal (overband magnet) offer superior strength and reliability and are designed for separation of ferrous metal from kinds of belt conveyed products. The advanced design and construction make overband magnets (crossbelt magnets) ideal for use in recycling, fire shredding, wood chip, and demolition applications.

Magnet System | Permanent Magnet |

Frame Material | Stainless Steel 304 |

Drum Bearing | UCFC |

Discharge Belt | EP100 10mm thickness |

Belt Cleats | Vacunized Rubber or SS 304 |

Gearbox | KA helical-bevel gear units |

Motor | IP 55 |

Standard Color | RAL 5015 |

Power Supply | Client's Site Specs |

Detailed images