Vibratory feeders are essential devices in various industrial processes, providing an efficient and reliable method for moving and controlling the flow of bulk materials. These feeders are widely used across industries such as manufacturing, mining, pharmaceuticals, and food processing. They ensure that materials are transported smoothly, precisely, and consistently, which is crucial for maintaining the quality and efficiency of the production process. This article explores the different types of vibratory feeders, including electromagnetic feeders, vibrating feeder hoppers, vibrating pan feeders, magnetic vibratory feeders, and vibro feeder machines, highlighting their roles and importance in material handling. Electromagnetic Feeder: Precision in MotionThe electromagnetic feeder is a type of vibratory feeder that uses electromagnetic energy to drive the movement of materials. This electromagnetic feeder is known for its precise control over material flow rates, making it ideal for applications where accuracy is critical. The electromagnetic feeder operates by generating vibrations through an electromagnetic drive, which moves the material along the feeder tray. This method allows for quick start and stop actions, providing a high level of control over the feeding process. Industries such as pharmaceuticals, where small amounts of material need to be dispensed accurately, often rely on electromagnetic feeders. Vibrating Feeder Hopper: A Versatile Material Handling SolutionA vibrating feeder hopper is a versatile component that combines the storage capabilities of a hopper with the controlled feeding of a vibratory feeder. This setup is commonly used in situations where large volumes of bulk materials need to be stored and then fed into a process line at a controlled rate. The vibrating feeder hopper ensures a consistent flow of material, preventing issues such as clogging or material buildup. Vibrating feeder hopper is particularly useful in industries like mining and construction, where handling large quantities of raw materials is common. Vibrating Pan Feeder: Smooth and Even DistributionThe vibrating pan feeder is designed to handle heavy loads and provide a smooth and even distribution of materials across a production line. Unlike other feeders that may use a trough or tube, the vibrating pan feeder features a flat, open surface that allows materials to be spread out evenly. This design is especially beneficial when working with materials that need to be separated or screened before further processing. The vibrating pan feeder is commonly used in industries such as mining, quarrying, and recycling, where large and abrasive materials are processed. Magnetic Vibratory Feeder: Controlled Material FlowA magnetic vibratory feeder operates similarly to the electromagnetic feeder, using magnetic forces to create vibrations that move materials along the feeder tray. However, magnetic vibratory feeders are often preferred in applications where a non-contact method of moving materials is desired. This type of feeder is ideal for handling delicate or sensitive materials that could be damaged by direct contact with mechanical parts. The magnetic vibratory feeder provides a consistent and controlled flow of material, making it suitable for use in the food and pharmaceutical industries. Vibro Feeder Machine: Efficiency in Bulk Material HandlingThe vibro feeder machine is a robust and efficient solution for bulk material handling. This vibro feeder machine of feeder is designed to handle a wide range of materials, from fine powders to large, coarse aggregates. The vibro feeder machine operates using vibration to move materials along the feeder tray, ensuring a steady and consistent flow. Vibro feeder machine versatility makes it a popular choice in industries such as mining, agriculture, and construction, where the ability to handle different types of materials is crucial. ConclusionVibratory feeders, including electromagnetic feeders, vibrating feeder hoppers, vibrating pan feeders, magnetic vibratory feeders, and vibro feeder machines, play a vital role in the material handling processes across various industries. Each type of feeder offers unique advantages, from precise control of material flow to the ability to handle heavy and abrasive materials. By understanding the specific functions and benefits of each vibratory feeder type, industries can optimize their material handling processes, leading to improved efficiency, reduced waste, and higher quality production outcomes. |

Production Overview

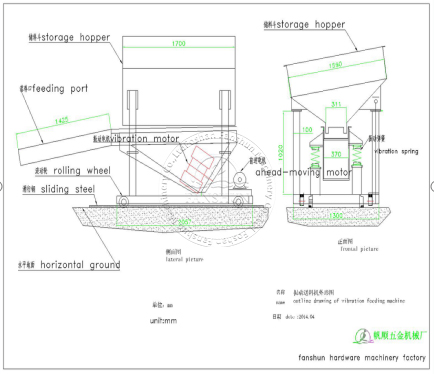

| The vibratory feeder is able to deliver lump, granular and powder materials from the storage bin or funnel to the furnace in an even and continuous manner. It feeds the material evenly according to the melting speed of the furnace, avoiding the oxidation of zinc to zinc ash at high furnace temperatures, increasing the melting speed and reducing energy consumption. |

Mainframe Structure

Parameter

| Motor | Power | Amount |

| Vibratory motor | MVM20-6,1.5KW | 2 |

| Forward motor | 3KW Pendulum needle | 1 |